Strukturele Versterking met Koolstofveselweefsel

Koolstofvezel masjeklaring speel 'n sleutelrol in moderne konstruksie deur die struktuur se dra- en lasvermoë aansienlik te verhoog. Dit versprei gewig gelykmatig deur die materiaal, wat die strukturele sterkte met tot 40% verhoog. Die integrasie van koolstofveselweefsel in geboue help om die veiligheid en veerkragtigheid te verbeter, wat noodsaaklik is vir duursame argitektuur.

Vergroting van Lasdraende Kapasiteit in Geboue

Op soek na maniere om geboue sterker te maak? 'n Redelik goeie benadering is koolstofveselgaas te kombineer met standaardboumateriale soos beton. Dit skep wat ingenieurs 'n saamgestelde sisteem' noem, wat werklik beter teen dinge soos aardbewings en sterk winde weerstaan. Ons het gesien hoe hierdie tegniek wonderwerk verrig op verskeie onlangse bouperse waar geboue baie groter stabiliteit oor tyd getoon het. Aannemers begin koolstofveselgaas nie meer sien as net nog 'n materiaalopsie nie, maar as iets wat werklik strukturele integriteit in moderne argitektuur kan transformeer.

Integrasie met Bestaande Strukturele Komponente

Die integrering van koolstofveselgaasdoek met bestaande komponente bied naadlose versterking sonder omfattende wysigings. Wat is die voordele daarvan? Hierdie benadering voordel stadsmilieus deur tydverlies en onderbrekings te minimeer. Die kompatibiliteit van koolstofveselgaas met verweerde beton verbeter die werkverrigting sonder uitgebreide herstellingswerk, wat die lewensduur van ouer infrastrukture verleng.

Verskeie suksesvolle stedelike gevallestudies toon verminderde koste en verlengde lewensduur vir strukture wat behandel is met koolstofveselgaas. Hoe verhoog hierdie materiaal die doeltreffendheid? Verhoogde kompatibiliteit versterk die doeltreffendheid, wat koolstofvesel geskik maak vir 'n wye verskeidenheid bouprojekte, en dit brei ingenieursgrense uit sonder om die gehalte of duursaamheid op te offer.

Betonherstel- en Rehabilitasiemetodes

Afskilfering en Spel Herstel

Koolstofveselmeshdoek lewer wonders uit wanneer dit gaan oor delamineringprobleme in ou betonkonstruksies. Die materiaal maak vinnige herstelwerk moontlik wat geboue sterk laat staan sonder dat alles uitmekaar geskeur moet word. 'n Groot voordeel is hoeveel vinniger hierdie werk gedoen word in vergelyking met tradisionele metodes, wat beteken dat besighede nie vir weke lank hul bedryf hoeft te sluit nie. Werklike toetse toon dat selfs na jare van blootstelling aan ekstreme weerstoestande, oppervlakke wat met koolstofvesel herstel is, hul sterkte en voorkoms behou. Kontrakteurs regoor die land keer toenemend na hierdie oplossing terug omdat dit eenvoudig sin maak vanuit 'n veiligheidsoogpunt sowel as 'n begrotingsperspektief.

Skeurvoorkoming en Struktuurbehoud

Koolstofveselmaas help verhoed dat beton soveel skeur. Wanneer bouers hierdie maas by hul mengsels voeg, verminder dit werklik die verergende skeure wat ontstaan terwyl die beton nog aan die uithard word is. Die materiaal werk deur die uitrekkraggte te weerstaan wat die beton wil laat uitmekaar trek. Werklike toetse toon dat geboue met koolstofveselmaas geneig is om ongeveer 30 persent minder te skeur nadat alles geset het. Dit beteken strukture wat langer hou. Navorsers ondersoek hierdie materiaal al jare lank, en hul bevindings wys steeds soortgelyke resultate. Vir enigiemand wat vandag met beton werk, is dit sinvol om van koolstofveselmaas te weet, want dit maak werklik 'n verskil in hoe goed projekte met die tyd hou.

Verbetering van Voorafgegote Betonelemente

Liggewigpanele en Verminderde Materiaalverbruik

Die koolstofvesel-mashef doek maak werklik 'n verskil wanneer dit by die vervaardiging van die lig gewig voorafgegote betonpaneel kom wat ons so baie sien in hierdie dae. Kontrakteurs hou daarvan omdat dit baie makliker is om te verskuif en aan te bring, wat die vervoerkoste en al die ekstra werk op die boupersele verminder. Sommige studies het getoon dat bouers hul materiaalbehoeftes werklik met ongeveer 25% kan verminder sonder om die sterkte van die panele te kompromitteer nie. En kom ons wees eerlik, hierdie soort innovasie ondersteun beslis die groen bou doelwitte. Die meeste argitekte van vandag wil hul omgewingsvoetdruk oral verminder waar dit moontlik is, en hierdie tegnologie help hulle om dit te bereik terwyl hulle steeds goeie resultate uit hul projekte verkry.

Ontwerp Buigsaamheid vir komplekse Argitektoniese Vorms

Argitekte wat aan ingewikkelde gebouontwerpe werk, vind koolstofveselmaas ongelooflik nuttig omdat dit hulle die nodige buigsaamheid bied. Die materiaal laat toe dat geboue gekke vorms en gedetailleerde patrone aanneem wat andersins onmoontlik sou wees om te bereik sonder dat die struktuur verloor aan sterkte. Wanneer argitekte saamwerk met ontwerpers wat hierdie materiaal verstaan, skep hulle ruimtes wat nie net goed lyk nie, maar ook sterk bly. Baie professionele mense in die veld gebruik koolstofveselmaas gereeld omdat dit die deur oopstoot vir kreatiewe ontwerpe wat hul sterkte en duursaamheid behou oor tyd.

Korrosiebestande Versterking vir Duursaamheid

Koolstofveselmaasdoek word toenemend aanvaar vir sy korrosiebestandheid in brugkonstruksie, wat onoortreflike duursaamheid bied. Dit is veral voordelig in streke met harde omstandighede, aangesien die lewensduur van koolstofveselversterkte brûe dikwels 100 jaar oorskry. Talle studies wys op beter werkverrigting as staal of beton.

Versterkingsmetodes vir Hoë-verkeersinfrastruktuur

Koolstofveselgaas het 'n gewilde materiaal geword vir die versterking van besige brûe regoor die land. Die manier waarop hierdie gaasse werk, is redelik eenvoudig – hulle help om die gewig beter te versprei en baie swaarder verkeer te hanteer as wat tradisionele materiale kan hanteer. Neem byvoorbeeld onlangse brugverbeteringe in stedelike gebiede. Ingenieurs het noemenswaardige verbeteringe in beide strukturele integriteit en algehele stabiliteit na installasie opgemerk. En kom ons wees eerlik, niemand wil hê dat hul reisroute vir maande lank ontwrig word nie. Dit is hoekom talle vervoerdepartemente nou na koolstofvesellosings kyk vir brugherstel. Hierdie materiale maak vinniger herstel moontlik sonder om heeltemal lane te sluit, wat beteken minder frustrasie vir bestuurders en 'n vinniger terugkeer na normale bedryf.

Seismiese Naverhardingsoplossings in Aardkwakhoekegebiede

Buigsame Versterking vir Strukturele Beweging

Die buigsaamheid van koolstofveselgaas speel 'n groot rol in hoe geboue aardbewings trotseer. Wanneer bewings optree, absorbeer hierdie materiale skokgolwe en versprei die energie deur die struktuur in plaas van dit in een punt te laat konsentreer. Veldtoetse wat in plekke soos Japan en Kalifornië gedoen is, toon dat die opgradering van ou geboue met koolstofvesel werklik skade verminder na groot aardbewings. Werk hierdie materiaal wanneer die grond begin beweeg? Beslis. Die materiaal laat geboue toe om net genoeg te beweeg sonder om heeltemal inmekaar te stort, wat beteken 'n veiliger omgewing vir mense binne, terwyl dit ook beskerm teen katastrofiese struktuurverswye oor tyd.

Gevallestudies in Seismiese Sone Konstruksie

Verskeie gevallestudies beklemtoon die doeltreffendheid van koolstofvesel in seismiese opgraderingsprojekte. Die konstruksie- en ingenieurswese-sektore verkry insigte oor beste praktyke uit hierdie studies en neem lesse oor toekomstige seismiese sone-konstruksie. Hoe dra koolstofvesel by? Dit speel 'n sleutelrol in holistiese katastrofevoorbereidingsstrategieë.

Voordele bo Tradisionele Versterkingsmateriale

Gewigvermindering teenoor Staalweefsel

Koolstofveselmaasdoek tree op as 'n alternatief vir tradisionele staalmaas weens sy ligter gewig. Hierdie verminderde gewig verlaag die algehele las en verbeter vervoer en installasie. Projekte profiteer deur verbeterde sterkte-teenoor-gewig-verhoudings, wat lei tot tot 70% gewigvermindering terwyl werkverrigting behou word.

Duurzaamheid in Swaar Omgewingstoestande

Wat maak koolstofveselmaas duursaam? Dit weerstaan roes en degradasie effektiewer as staal, wat dikwels die prooi van korrosie oor tyd word. Die veerkragtigheid van koolstofvesel ondersteun volhoubaarheid deur die frekwensie en koste van vervanging te verminder, wat dit 'n uitstekende keuse maak in rowwe omgewings.

FAQ

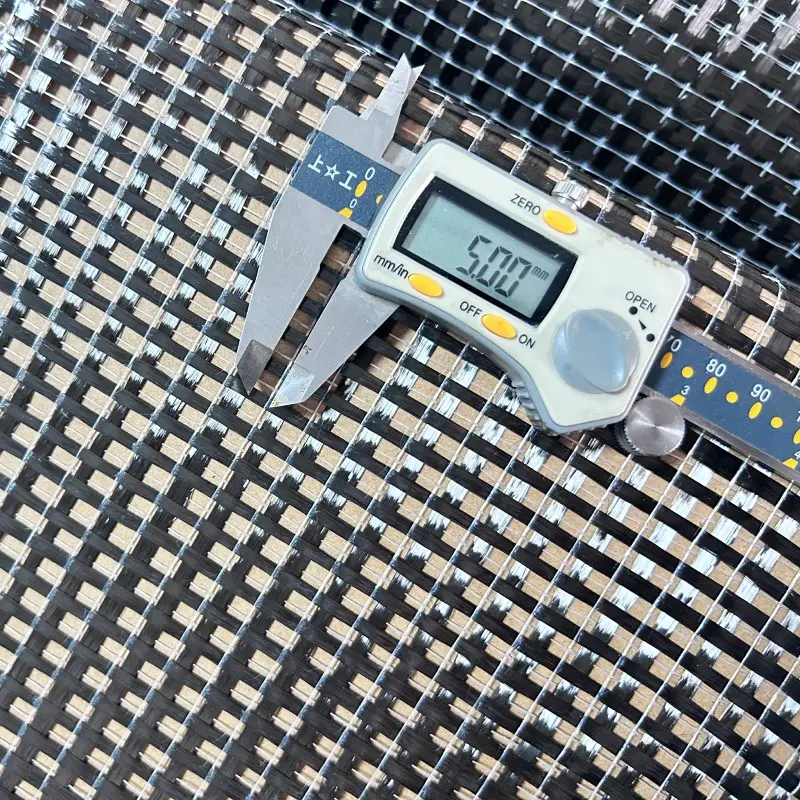

Wat is koolstofveselgaasdoek?

Koolstofveselmaasdoek is 'n versterkingsmateriaal wat in konstruksie gebruik word om strukturele sterkte en integriteit te verbeter.

Hoe help Koolstofveselmaas met dra-vermoë?

Dit versprei gewig gelykmatig, verhoog sterkte met tot 40% en verbeter veiligheid en veerkragtigheid in geboue.

Kan Koolstofveselmaas saam met ouer strukture geïntegreer word?

Ja, dit kan aan ou beton gebind word en die lewensduur verleng sonder omvangryke herstellingswerk.

Wat is die voordele van die gebruik van koolstofvesel in bruggestrukture?

Koolstofvesel bied korrosiebestandheid, verbeter die lewensduur, werking en openbare veiligheid.

Waarom is koolstofveselnet voordelig vir aardbewingsgebiede?

Sy buigsaamheid absorbeer seismiese kragte, behou die struktuur se integriteit en verminder die risiko van struktuurskade.

Inhoudsopgawe

- Strukturele Versterking met Koolstofveselweefsel

- Betonherstel- en Rehabilitasiemetodes

- Verbetering van Voorafgegote Betonelemente

- Korrosiebestande Versterking vir Duursaamheid

- Versterkingsmetodes vir Hoë-verkeersinfrastruktuur

- Seismiese Naverhardingsoplossings in Aardkwakhoekegebiede

- Voordele bo Tradisionele Versterkingsmateriale

- FAQ