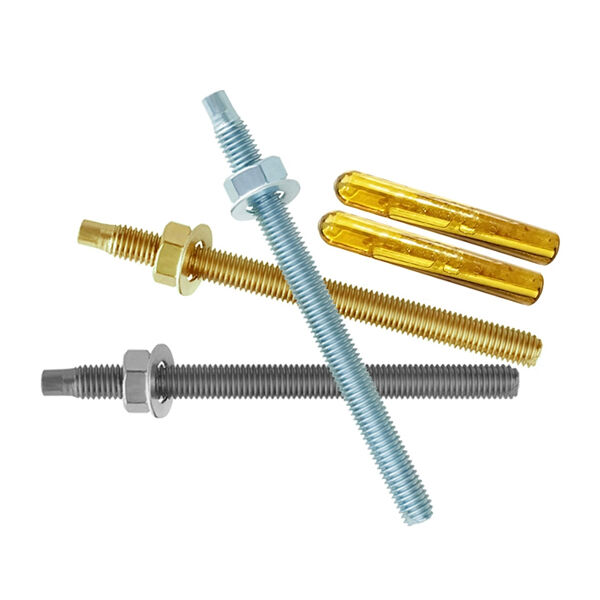

structural reinforcement adhesive free sample

Structural reinforcement adhesive free samples represent cutting-edge bonding technology designed to enhance structural integrity across various applications. These advanced adhesive solutions offer exceptional strength and durability, specifically engineered to create permanent bonds between different materials including metals, composites, and plastics. The formulation combines high-performance epoxy resins with specialized hardeners, delivering superior mechanical properties and resistance to environmental factors. These samples provide users with the opportunity to test the adhesive's remarkable load-bearing capabilities, thermal resistance, and chemical stability before committing to larger quantities. The technology behind these adhesives incorporates innovative cross-linking mechanisms that ensure optimal cure rates and minimal shrinkage during the bonding process. With working times tailored to various industrial applications, these samples demonstrate excellent gap-filling properties and the ability to bond substrates with different thermal expansion coefficients. The free samples typically come with comprehensive technical documentation, including application guidelines, surface preparation requirements, and performance data, enabling users to evaluate the adhesive's suitability for their specific needs.