Advanced Materials in Safety Apparel

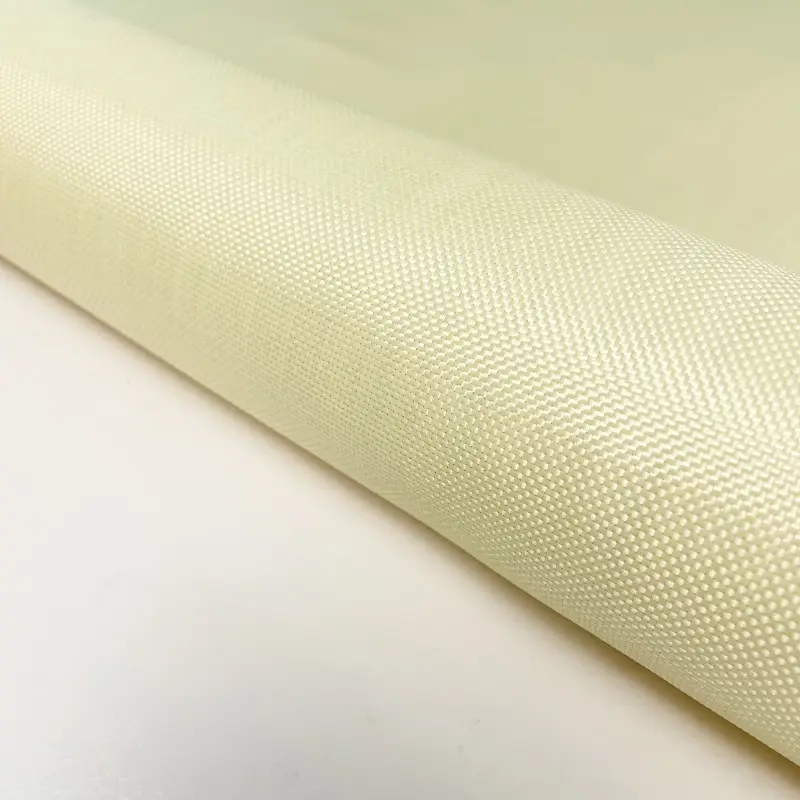

Protective clothing has experienced a significant evolution over the past few decades. Today’s protective garments are designed not only to safeguard the wearer but also to enhance comfort and performance in extreme environments. Modern professionals such as firefighters, industrial workers, and military personnel require materials that combine strength, flexibility, and resilience. Among these, Aramid Fiber Fabric has emerged as a leading material due to its unique characteristics. Its lightweight construction, high tensile strength, and remarkable thermal and chemical resistance make it an essential component in protective clothing across a variety of industries.

In addition to its physical properties, Aramid Fiber Fabric offers longevity and reliability, which reduce the need for frequent replacements, a crucial factor in professional environments where safety cannot be compromised. Manufacturers increasingly rely on aramid fiber fabrics to create garments that can withstand extreme conditions while remaining comfortable for extended wear.

Composition and Key Characteristics of Aramid Fiber Fabric

Molecular Structure and Exceptional Strength

Aramid Fiber Fabric is composed of aromatic polyamide chains, which align in highly organized structures. This molecular alignment is key to its exceptional tensile strength. Each fiber efficiently distributes applied forces, minimizing the risk of tearing or deformation under high stress. This property is especially critical in protective clothing, where the integrity of the material can mean the difference between safety and injury.

The superior strength of Aramid Fiber Fabric also allows designers to create thinner, lighter garments without sacrificing protection. This lightweight yet robust nature contributes to improved mobility and comfort, essential for professionals who need to move quickly and efficiently in hazardous environments.

Thermal Resistance and Chemical Stability

One of the most compelling features of Aramid Fiber Fabric is its resistance to extreme heat and chemical exposure. Unlike conventional textiles, aramid fibers do not melt or degrade easily when exposed to flames, sparks, or corrosive substances. This makes it an ideal choice for firefighters and industrial workers who encounter high temperatures or hazardous chemicals on a daily basis.

The fabric’s chemical stability ensures that it does not weaken or lose protective qualities over time, even under prolonged exposure to harmful substances. This durability is crucial in environments such as chemical plants, laboratories, or industrial manufacturing, where maintaining consistent protection is essential for worker safety.

Moisture and UV Resistance

In addition to heat and chemical resistance, Aramid Fiber Fabric exhibits excellent moisture and ultraviolet (UV) resistance. Unlike natural fibers that can degrade under sunlight or absorb moisture, aramid fibers maintain structural integrity and protective performance. This makes them suitable for outdoor applications where long-term exposure to environmental factors is inevitable.

Applications in Protective Clothing

Fire-Resistant Garments

Aramid Fiber Fabric is widely used in fire-resistant garments designed for firefighters, industrial workers, and emergency responders. These garments must withstand extreme heat, direct flames, and radiant energy without compromising safety.

The fabric’s exceptional thermal stability allows clothing made from aramid fibers to retain protective qualities even after prolonged exposure to fire or high temperatures. Multiple layers of aramid fiber fabric are often used in combination to enhance insulation, ensuring that wearers remain protected in the most dangerous scenarios. Its lightweight nature ensures that mobility and dexterity are not sacrificed, which is critical for emergency responders performing complex tasks under pressure.

Military and Law Enforcement Uniforms

Military and law enforcement personnel face unique threats, including ballistic impacts, explosions, and environmental hazards. Aramid Fiber Fabric is a preferred material for these uniforms because it offers superior impact resistance while remaining lightweight.

The ability of aramid fibers to absorb and distribute energy from projectiles and sharp objects enhances wearer protection. Additionally, the durability of aramid fiber fabrics ensures that uniforms maintain their performance under rigorous conditions, even during prolonged field operations.

Extreme Sports and Recreational Gear

Beyond professional use, Aramid Fiber Fabric is increasingly used in high-performance sports gear. Protective clothing for motorcyclists, rock climbers, and adventure athletes often incorporates aramid fibers to reduce the risk of injury. Its combination of strength, heat resistance, and abrasion resistance provides an added safety layer while allowing for flexible and lightweight designs suitable for active use.

Advantages Over Conventional Fabrics

High Strength-to-Weight Ratio

Aramid Fiber Fabric is renowned for its exceptional strength-to-weight ratio. Compared to traditional fabrics such as cotton or polyester, aramid fibers provide much higher tensile strength without adding bulk. This advantage is critical in protective clothing, where heavy materials can hinder mobility, reduce comfort, and lead to fatigue.

The lightweight nature of aramid fiber fabrics allows for garments that offer robust protection while remaining easy to wear for extended periods. Professionals in physically demanding fields benefit greatly from this combination of strength and agility.

Durability in Harsh Environments

Aramid Fiber Fabric excels in resisting wear, abrasion, and environmental degradation. Protective clothing constructed from aramid fibers maintains its structural integrity and protective qualities over time, even when subjected to repeated stress, UV exposure, or chemical contact.

Durability is a key factor in cost efficiency. Garments made from aramid fibers require less frequent replacement, which is particularly important in industries where worker safety is a priority and equipment must endure harsh conditions.

Resistance to Impact and Cutting

Another notable advantage of Aramid Fiber Fabric is its resistance to cutting and puncturing. This makes it suitable for applications such as gloves, protective sleeves, and other specialized gear where sharp objects may pose a threat. The fabric’s resilience adds an extra layer of safety that conventional materials cannot provide.

Integration with Modern Protective Gear

Layered Protective Systems

Protective clothing often incorporates Aramid Fiber Fabric as part of a layered design to maximize performance. These layered systems combine the benefits of aramid fibers with other materials to achieve optimal flame resistance, impact absorption, and comfort.

Each layer of aramid fiber fabric can serve a specialized function, such as thermal insulation, cut resistance, or moisture management. This modular approach allows designers to create garments tailored to specific occupational hazards while maintaining overall wearability.

Specialized Applications

Aramid Fiber Fabric is used in gloves, helmets, face shields, and padding, extending protection beyond standard uniforms. In these specialized applications, the fabric’s heat resistance, abrasion resistance, and mechanical strength enhance safety and durability.

For example, firefighting gloves made from aramid fibers protect hands from flames while preserving dexterity, while helmet linings incorporate aramid fabrics to absorb impact energy and reduce injury risks.

Industrial and Commercial Applications

Heavy Industry and Manufacturing

In heavy industry, manufacturing, and chemical processing, workers are often exposed to sparks, extreme temperatures, and abrasive surfaces. Protective garments made from Aramid Fiber Fabric offer a reliable barrier against these hazards.

The fabric’s combination of durability, heat resistance, and mechanical strength ensures that protective clothing can withstand daily exposure to harsh conditions without losing effectiveness. This reliability is crucial in minimizing workplace accidents and maintaining regulatory compliance.

Electrical and High-Voltage Environments

Aramid Fiber Fabric is also used in protective clothing for electrical workers and technicians. Its inherent resistance to heat and flames ensures that garments do not ignite or melt when exposed to sparks or electrical arcs.

By preventing burns and injuries in high-voltage environments, aramid fiber fabrics contribute to both safety and confidence for professionals working under dangerous conditions.

Advancements and Future Trends

Enhanced Composites and Blends

Recent innovations have focused on combining Aramid Fiber Fabric with other advanced materials to improve comfort, flexibility, and performance. These hybrid fabrics maintain the protective qualities of aramid fibers while enhancing moisture-wicking, breathability, and ergonomic fit.

Such innovations are especially important for industries where professionals must wear protective clothing for long shifts. Hybrid aramid fabrics reduce heat stress and improve mobility without compromising safety.

Smart Protective Clothing

The integration of smart textiles and wearable technology with Aramid Fiber Fabric is an emerging trend. Sensors embedded into aramid fibers can monitor heat exposure, impact forces, and other critical parameters in real-time.

This development has the potential to revolutionize protective clothing by providing data-driven insights, improving safety protocols, and allowing rapid response to emergencies. Aramid Fiber Fabric’s stability and durability make it an ideal substrate for these next-generation applications.

Sustainability and Recycling

With increasing focus on sustainability, research is exploring methods to recycle and reuse Aramid Fiber Fabric. Innovations in chemical recycling and fiber recovery could reduce environmental impact while maintaining the high performance standards required for protective clothing.

FAQ

Why is Aramid Fiber Fabric preferred in protective clothing?

Aramid Fiber Fabric offers unmatched tensile strength, heat resistance, and durability, making it highly suitable for protective garments in hazardous environments.

Can Aramid Fiber Fabric be used in fire-resistant, ballistic, and chemical-resistant clothing?

Yes, its versatile properties allow it to provide protection against heat, impacts, and chemical exposure, making it suitable across multiple protective applications.

How does Aramid Fiber Fabric compare to traditional fabrics?

Unlike cotton or polyester, Aramid Fiber Fabric maintains strength and stability under extreme heat, mechanical stress, and chemical exposure, providing superior long-term protection.

Is Aramid Fiber Fabric comfortable for long-term wear in industrial and emergency settings?

Yes, modern aramid fiber garments are designed for comfort, incorporating ergonomic design, breathability, and lightweight construction while retaining maximum protection.

What future innovations are expected in Aramid Fiber Fabric applications?

Advances include hybrid materials for better comfort, integration with smart sensors for real-time monitoring, and sustainable recycling methods to reduce environmental impact.

Table of Contents

- Advanced Materials in Safety Apparel

- Composition and Key Characteristics of Aramid Fiber Fabric

- Applications in Protective Clothing

- Advantages Over Conventional Fabrics

- Integration with Modern Protective Gear

- Industrial and Commercial Applications

- Advancements and Future Trends

-

FAQ

- Why is Aramid Fiber Fabric preferred in protective clothing?

- Can Aramid Fiber Fabric be used in fire-resistant, ballistic, and chemical-resistant clothing?

- How does Aramid Fiber Fabric compare to traditional fabrics?

- Is Aramid Fiber Fabric comfortable for long-term wear in industrial and emergency settings?

- What future innovations are expected in Aramid Fiber Fabric applications?