I. Carbon Fiber's "Force Philosophy": Weave as the Combat Code

Imagine carbon fiber tows as a highly trained elite force:

Frontal Assault (Tension): When force attacks along the fiber direction (parallel), the tightly connected soldiers display astonishing "tension muscles" (ultra-high tensile strength).

Flanking Attack (Shear): When force cuts in from the side (perpendicular), the unit's formation is easily disrupted (weaker shear strength). The wisdom of weave design lies in cleverly arranging the layout, transforming lateral impacts into the frontal resistance the fiber tows excel at!

II. The "Superpower Profiles" of Three Major Weaves: Structure Defines Battlefield Role

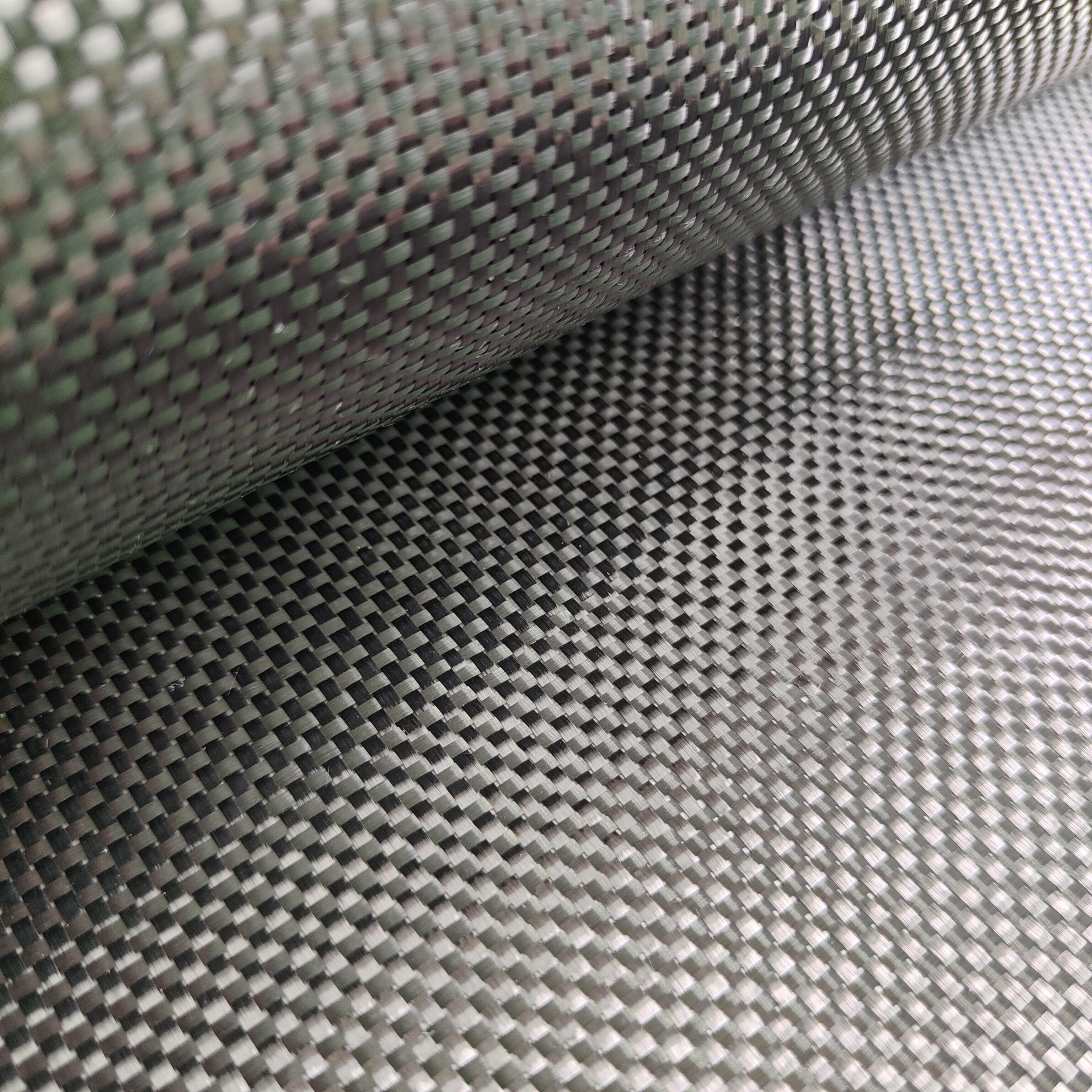

Plain Weave: The Orderly "Defensive Fortress"

Structural Secret: Warp and weft tows strictly follow the "one-over-one-under" rule, with dense crossover points like a checkerboard (think chessboard).

Trait Decoding:

Superb Stability: Rigid structure, minimal deformation, provides solid support.

Conformity Challenge: Lower bending/drapability; dense crossover points prone to slight "window effect" (eye holes) when covering complex curves.

Combat Arena: Fields demanding "rock-solid" performance – aerospace load-bearing structures, high-performance bicycle frames (extreme compression resistance & wear resistance).

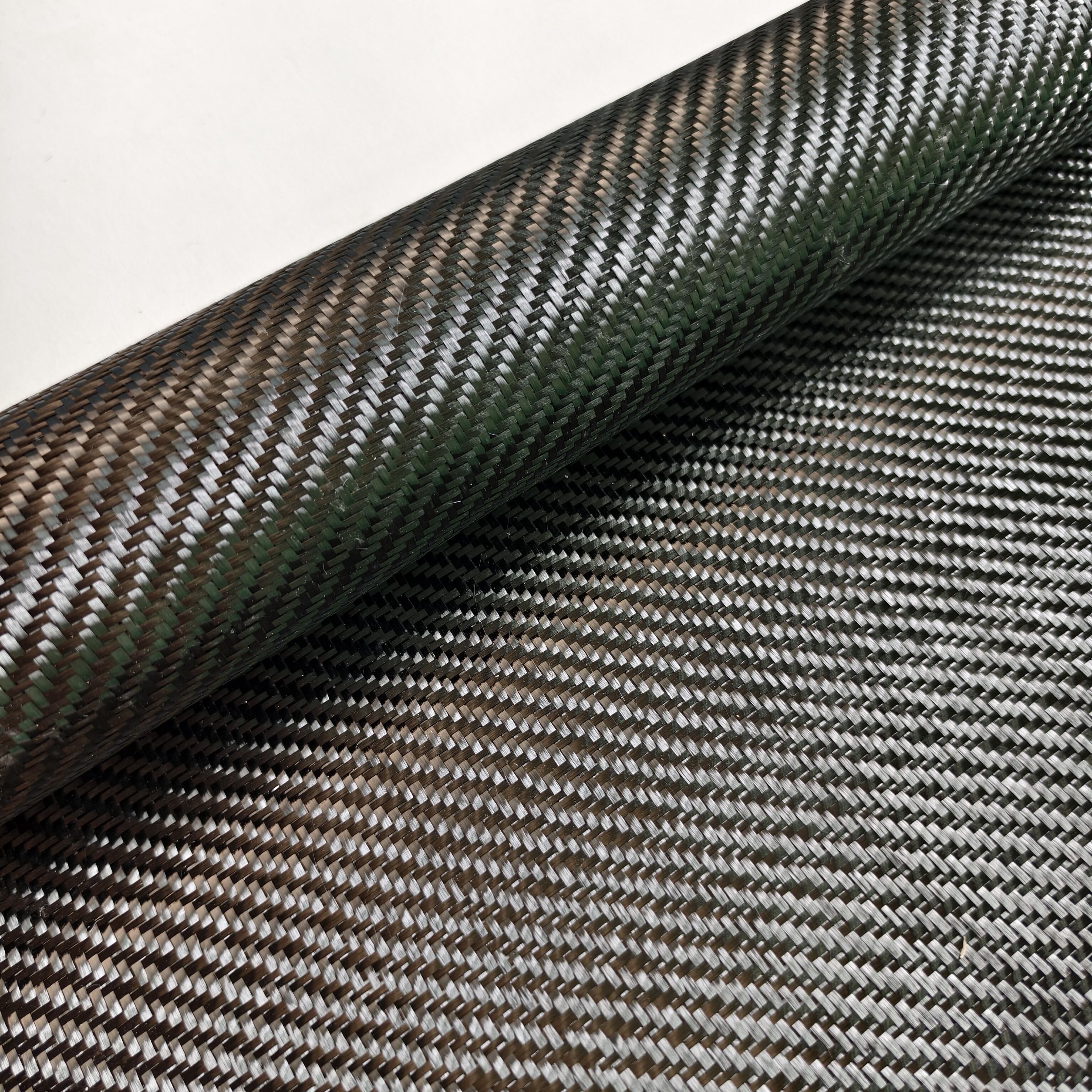

Twill Weave: The Agile "Rangers"

Structural Secret: Tows "step over" when interlacing (e.g., skip two before interlacing), forming distinctive continuous diagonal lines.

Trait Decoding:

Flexibility & Balance: Better drape and conformability than plain weave; performs better under tearing or impact (higher tear strength).

Visual Identity: Flowing diagonal lines create a unique 3D aesthetic.

Combat Arena: Intersection of automotive performance and aesthetics – hoods, aerodynamic spoilers (visual impact explosion!).

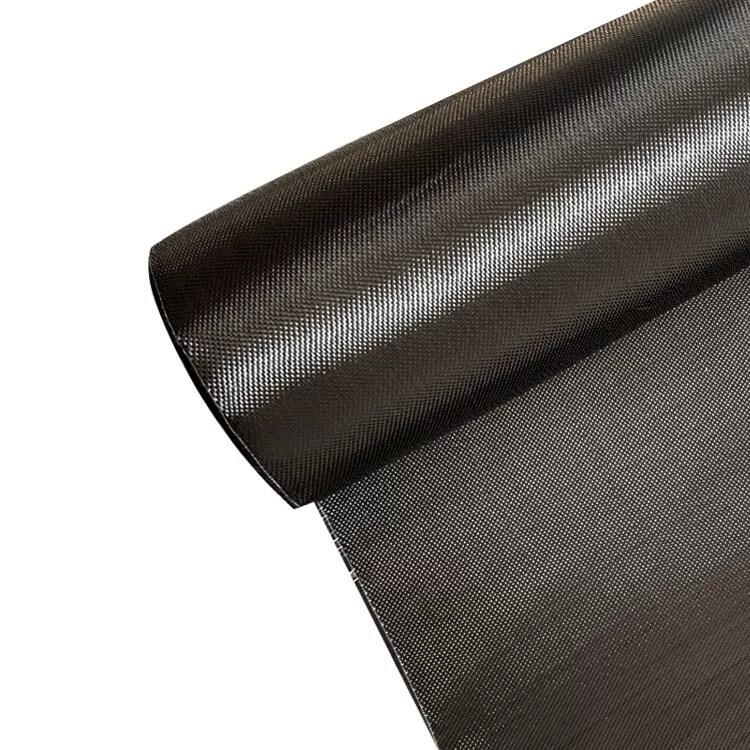

Satin Weave: The Elegant & Resilient "Special Forces"

Structural Secret: Tows perform "long-distance maneuvers" (e.g., interlace only after skipping 4 or more tows), creating long floats, resulting in an exceptionally smooth, flat surface.

Trait Decoding:

Curve Master: Excellent drape and conformability, easily mastering complex curves.

Smooth Aesthetic: Surface like silk or fine leather, presenting a premium matte-metal-like texture.

Strength Trade-off: Long floats mean relatively lower in-plane tensile strength, but interlayer bonding and impact resistance (burst resistance) are often superior.

Combat Arena: High-end applications & aesthetics-first domains – luxury yacht interiors, luxury accessories, components requiring an ultimate smooth surface.

III. More "Form Secrets": Expanding Performance Boundaries

Needled Felt: Three-dimensional fluffy "fiber cloud," excels at absorbing vibration and noise (e.g., automotive engine bay insulation).

Unidirectional Fabric / Non-Crimp Fabric (NCF): All tows aligned parallel, "united as one," locked by cured resin. Designed for extreme directional strength (e.g., rocket casings, high-performance tubes).

Hybrid Tech: Cleverly fuses different "spec soldiers" (e.g., 12K robust main force tows + 1K fine filler tows). Thick tows bear the load, fine tows fill the gaps, achieving breakthroughs in both strength and density!

Conclusion: Every Weave is a Precise Expression of Performance

Carbon fiber weave patterns are far from mere decoration; they are the core "combat posture" material engineers bestow upon products. Choosing the right weave means unlocking carbon fiber's unique "superpower," empowering your product to dominate on the journey of lightweighting.

Explore the "Light-Strong" Future! Dr. reinforcement provides high-performance carbon fiber bidirectional fabric solutions!

Contact our material experts immediately for samples & detailed technical specifications. Experience how carbon fiber weave magic empowers your product to:

Shatter weight limits

Define performance peaks

Win in every gram!

Dr. reinforcement – Your Trusted Lightweighting Partner

Email: [email protected]

WhatsApp: +86 191 2115 7199

Hot News

Hot News