In the field of carbon fiber reinforcement, "K-number" is often misunderstood as an indicator of strength. As a professional supplier of reinforcement materials, Shanghai Dr. Reinforcement clarifies the concept and reveals the core selection criteria for high-quality carbon fiber fabric – balancing advanced raw materials with exquisite craftsmanship.

I. K-Number Essence: The "Thickness Gauge" of Fiber Tows

Scientific Definition: K-number refers to the number of individual filaments contained in a single carbon fiber tow (1K = 1000 filaments). For example:

3K = 3,000 filaments/tow (finer texture)

12K = 12,000 filaments/tow (higher efficiency)

Core Impact: K-number determines the thickness of the fiber tow and the fabric's appearance, but does not directly determine strength.

Dr. Reinforcement Insight: Blindly pursuing a high K-number ≠ obtaining high-strength material! The key lies in the fiber grade and production process.

II. Strength Core: T-Value Grade is the Performance Cornerstone

Industry Gold Standard: T-value (e.g., T300, T700), established by Toray, is the core grade identifier for carbon fiber strength/modulus. A higher T-value indicates superior performance.

Key Understanding: Under the same T-value, filaments from different K-number fibers have identical performance.

Example: T300/3K and T300/12K filaments have the same strength; the higher strength of the 12K tow comes from the greater total fiber volume.

Dr. Reinforcement Core Advantage: We meticulously select imported high-grade T-value carbon filaments, fundamentally guaranteeing the material's mechanical performance ceiling.

III. The Code to Excellence: Process Barriers Beyond K-Number and T-Value

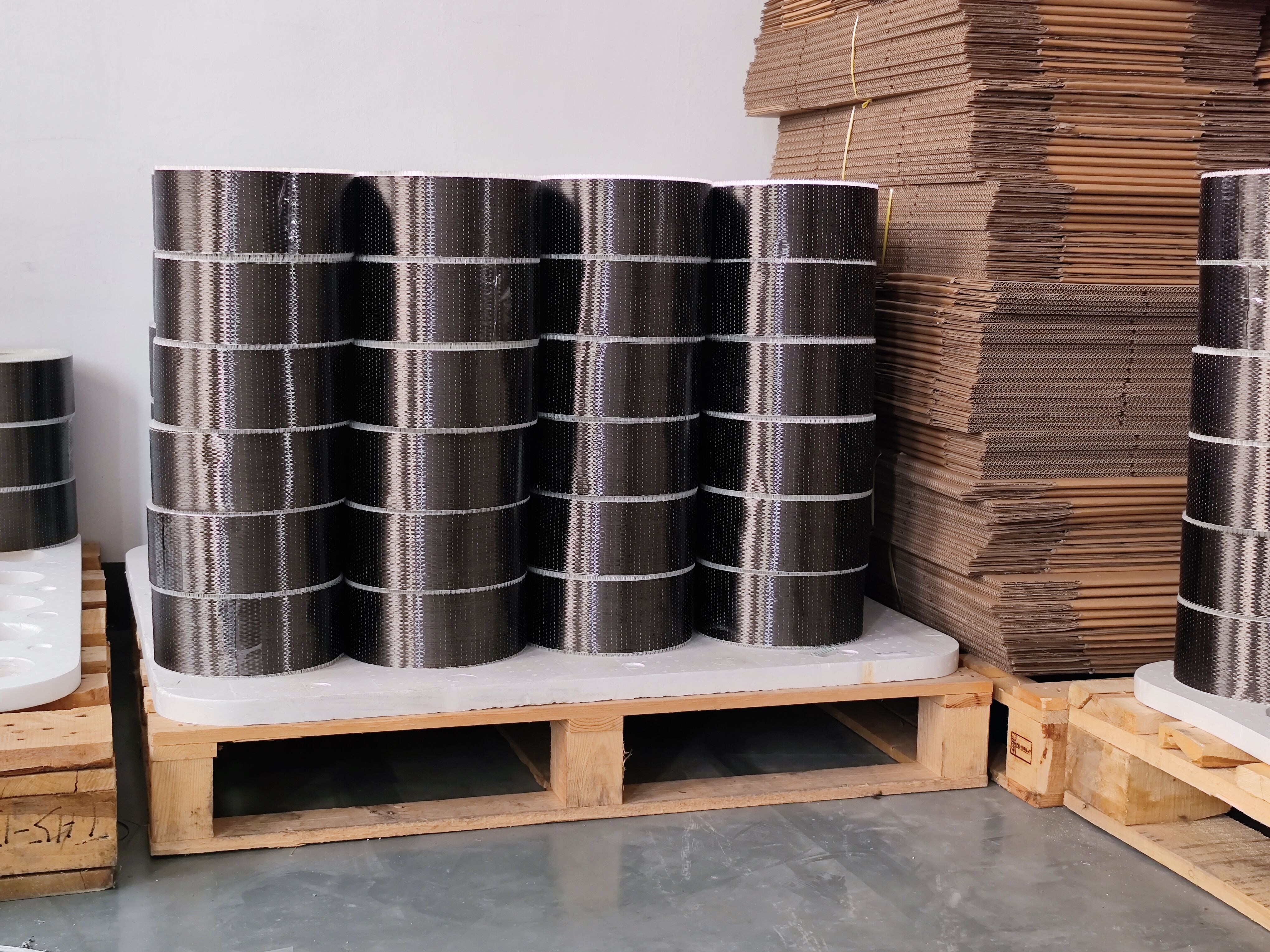

The final strength and reliability of carbon fiber fabric depend 50% on the fiber itself and 50% on the manufacturing process. Dr. Reinforcement builds every roll to aerospace standards:

Tow Science: Using 12K Small Tows

Better Impregnation: Compared to large-K tows, the 12K structure has more rational voids, ensuring resin fully envelops each filament, enhancing interlaminar strength and durability after compositing.

Lower Dispersion: More uniform fiber distribution ensures stable and reliable tensile performance.

Fiber Quality: Ultra-Long Continuous & Aerospace-Grade Precursor

Filament Length ≥ 5,000 meters: Guarantees continuity from the source.

100-meter rolls, no splices: Eliminates weak splice zones, ensuring uniform strength throughout the entire roll and worry-free construction. (Industry Pain Point: Splices are potential fracture points).

Weaving Pinnacle: Precision Engineering with German Dornier Looms

Extremely Stable Filament Output: Precise tension control system minimizes fuzz and broken filaments.

Uniform & Smooth Fabric Surface: Dense, flat weave structure facilitates resin flow and penetration, improving construction quality and final strength.

Strict Defect Control:

Near-Zero Defects: Strict control of fuzz, stains, and wrinkles eliminates weak points in strength.

Dr. Reinforcement Value Proposition: We not only provide high T-value carbon filaments but also convert theoretical strength into real-world high performance in engineering through our combination of scientifically optimal 12K tow structure + splice-free long filaments + German weaving technology.

Conclusion: Choose High-Quality Carbon Fabric, Trust Dr. Reinforcement Aerospace Standards

Debunk Myths: High K-number ≠ High strength! T-value is the strength benchmark; process is the performance guarantee.

Key Selection Criteria: Focus on: ① Carbon fiber T-value grade ② Rationality of tow structure ③ Manufacturing process level ④ Defect control capability.

Dr. Reinforcement Commitment: We specialize in high-end reinforcement materials, insisting on using:

Imported high T-value aerospace-grade carbon filaments

12K small tows for superior impregnation

5,000-meter long filaments woven into 100-meter rolls (no splices)

German Dornier precision weaving

Near-zero defect quality control

Choosing Dr. Reinforcement carbon fiber fabric means choosing: Aerospace-grade raw materials, German-crafted precision, stable and reliable high strength!

Contact Shanghai Dr. Reinforcement today to get your aerospace-grade carbon fiber reinforcement solution!

Email:[email protected]

Whats/Tel:+86 19121157199

Hot News

Hot News