Intellegendo Textum Carbonii Reticulatum

Compositio et Processus Fabricationis

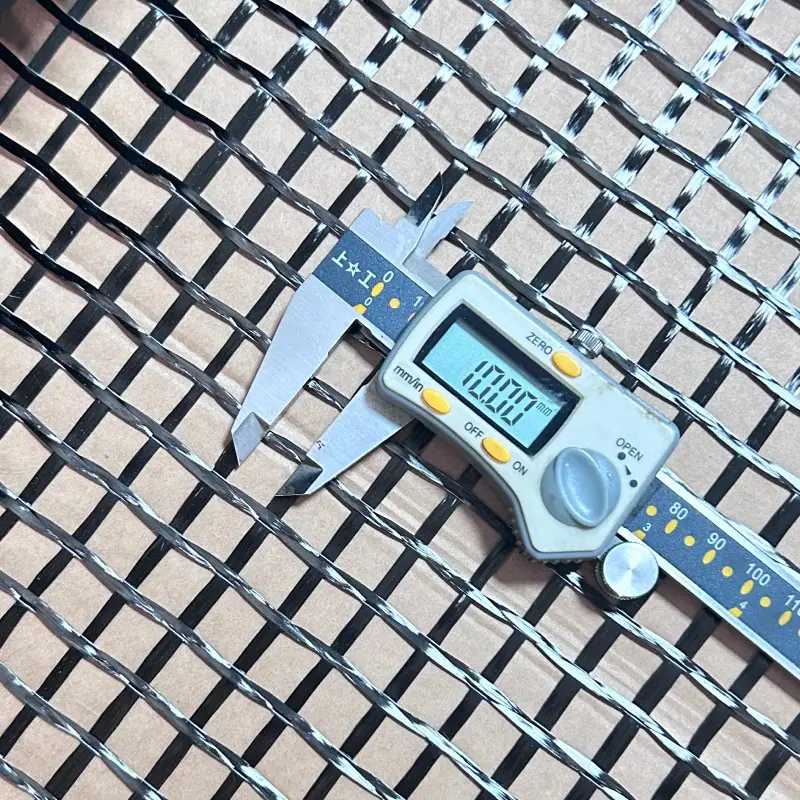

Textus ex carbonum fibris mirum vis attentionis habet quia valde fortis tamen levis est. Primum quidem incipit a carboni fibris quae in fila contorquentur. Deinde venit textura qua fila in figuras varie textas disponuntur pro functione materiae in futuro. Fabricare hanc rem non facile est. Primo, carboni filamenti in fila veras converti debent per artes speciales. Post texturam, varia tractamenta adhibentur ut tela contra vim sustineatur et bene operetur diuturno tempore. Saepius respublicae utuntur rebus sicut methodis infundendi resinam et calefactionis regulatae in productione ut ultimum opus vim additam adipiscatur. Praeterea, tegumenta superficialia etiam munere suo funguntur, ut carbonii textus facile coniungatur cum in structuris quae roborationem postulant utatur.

Proprietates Principales Textilis Carbonis

Textus ex carbonum fibris mirabilem rationem firmitudinis ad pondera ostendit, ita ut graves onus ferre possit sine multa magnitudine addita. Ideo ingeniatorum animos capit, cum aliquid roboris indigent sed non nimis grave esse debet. Alius magnus praetextus est, quomodo diuturne vim tolerantiam sustinet. Structurae ex hoc textu factae non facile rumpuntur, etiamsi post annos pressionis et remissionis cotidie constant. Parum dilatatur, cum temperatura mutatur, quod eam stabilem reddit, sive in frigoribus sive in calidis locis adhibeatur. Praeterea carbonum fibra valde bene electricitatem ducit, tamen caloris translationem minime promovet. Haec praecipua in multis artibus et fabricationibus, ut in aeronautica et automobilorum manufactura, ubi tum usus tum efficacia maxime ponderantur, sunt utilis.

Haec praerogativa capita faciunt ut textus ex carbonum fibris ad industrias necessarius sit, adiuvans aedificia et machinas caeli fabricandas. Eius varietas et fides structuras firmas et meliores efficere possunt, tutitudinem et expeditionem conservantes.

Commoda Textilis Carbonii Fibrosi in Molebus Roborandis

Altus Rationis Fortitudinis ad Ponderem

Rationes inter se fortis et levis textus carbonii fibrosi sunt ingenii novatores. Efficiunt ut aedificia leviora et utiliora sine periculo firmitatis molis construi queant, igitur constructiones transfigurantes. Itaque celeritas in aedificando ducit ad minores sumptus materiae et breviores tempora operis.

Resistentialis Corrosioni et Durabilis

Textus ex carbonum fibris praebet excellentem resistentiam ad corrosionem, quae est necesse pro applicationibus in locis umidis et chemice aggressivis. Obstinatio eius ad istas condiciones adversas significanter auget tempus vivendi structurarum armatarum, efficaciter minuendo frequentiam et sumptus coniunctos cum custodia.

Applicationes Texti Carbonii Fibrosi

Rehabilitatio Structurae Concretae

Textus carbonii fibrosi magis magisque adhibetur in reficiendis structuris concretis propter levi tamen fortis proprietates. Applicationes huius materiae saepe comprehendunt technicas ligandi superficiei quae integrationem omnimodam cum structuris existentibus firmant, ita robur earum augebant.

Retrofitting Seismica et Praeventio Calamitatum

Textus ex fibris carbonii reticulatus munere magno fungitur in restaurando structurae ad motus telluris resistendum, vim structurae ad onera sismica sustinenda augendo et ita tutitudinem ac perficientiam generalem meliorans. Artus critici et loca infirma roborando, textus ex fibris carbonii casum catastrophicum perimendi per eventus sismicos minuit.

Commentarius de Carbon Fiber Mesh Systems Instaurandis

Technicae Praeparationis Superficiem

Instauratio recta a diligenti praeparatione superficiei incipit ut coniunctio optima inter textum ex fibris carbonii et superficierum existentium fiant. Hoc comprehendit purgare superficiem ut omnis debris removeatur, emendare quasdam iniurias, et saepe praeparatoria adhibere ut vis adhaerendi meloretur.

In Matricibus Cementitiis Infigere

Carbon fiber mesh in matricibus cementitiis infigere necessarium est ad distributionem efficacem onerum et integritatem structuralem meliorem. Hoc processus mixtionem et applicationem cautam requirit ut dispersio uniformis fibrarum intra matricem obtineatur.

Comparatio Analytica: Rete Carbonii Fibrosi vs. Renovationes Tradicionales

Praestantia in Testibus Tensionis

Quando ad vim extensionis attinet, textus carbonii fibrosi constantius praestat quam tradicionalis roborationes ferreae. Studia demonstrant carbonium fibrosum vim extensionis superantem 2000 MPa attingere posse.

Costus Conservatus Longe-Term

Licet initialis impensae rete carbonii fibrosi formidabilis videatur, tamen longo tempore curae impensae multo minores sunt comparata cum materialibus tradicionalibus. Eius incredibilis durabilitas et resistentia corrosioni significat structuras carbonio fibroso roboratas minus curae per totam vitae span requirere.

Curatio et Securitas Qualitatis

Testis Resistentiae Ambientalis

Testis routine resistentiae ambientalis maximi momenti est ad qualitatem rete carbonii fibrosi servandam pRODUCTS per varia conditionum climaticarum. Hoc processu testis radiatio UV, humiditas, et variationes temperaturae subiiciuntur ut firmitas et durabilitas eius aestimetur.

Conformitas cum Normis Industriae

Ad normas industriales sicut ASTM vel ISO adhaerere necesse est ut carbofibrosi producti qualitatem et praestationem gaudeant. Haec normae directiones copiosas de testando et certificando praebent, quae ad probandum opus et praestandas praestationes diuturnas sunt necessariae.

Innovationes Futurae in Polymers Reforcatis Fibris

Integratio Retei Intelligentis

Futurum polymerorum reforcatorum fibris nitidum est, cum innovationibus magnis iam appropinquantibus, quae praecipue circa rete intelligentis integrationem versantur. Haec progressio sensorum technologias in textilibus carbonii fici systematibus condere vult, ut solutio "rete intelligens" creetur, quae valet structuralem sanitatem inspicere.

Methodi Productionis Sustentabiles

Impetus pro sostenibilitate in productione polymerorum reforcatorum fibris crescit, cum rationibus fabricandis amicis erga naturam insistatur. Methodi novi emergunt qui nituntur pedis vestigia carbonis minuere et materiales recyclatos in polymerorum reforcatorum matrices includere.

Sectio FAQ

Quid est pannus textilis carbonii fici?

Textus ex fibra carbonii est materialis fortis et levis, contextus e fibris carbonii textis, adhibitus in multis applicationibus structurae propter durabilitatem et praestantiam.

Cur preferatur textus ex fibra carbonii in aedificatione?

Textus ex fibra carbonii praefertur pro ratione altitudinis fortis ad levitatem, resistentia ad corrosionem, et excellentia in fessa, idoneus igitur ad roborandam structuram.

Quomodo textus ex fibra carbonii utitur in restaurando aedificio ad terremotum?

Textus ex fibra carbonii auget facultatem structurae onera terrae motus ferendi roborando iuncturas criticas et partes infirmas, ita tutelam generalem meliorem efficiens.

Quae sunt emolumenta usus texti ex fibra carbonii in renovatione tui cementi?

Usus texti ex fibra carbonii in renovatione tui cementi solutiones leves et durabiles praebet quae cum structuris existentibus integrantur, restituendo vim et vitam operativam prolongando.

Index Rerum

- Intellegendo Textum Carbonii Reticulatum

- Commoda Textilis Carbonii Fibrosi in Molebus Roborandis

- Applicationes Texti Carbonii Fibrosi

- Commentarius de Carbon Fiber Mesh Systems Instaurandis

- Comparatio Analytica: Rete Carbonii Fibrosi vs. Renovationes Tradicionales

- Curatio et Securitas Qualitatis

- Innovationes Futurae in Polymers Reforcatis Fibris

- Sectio FAQ