Verstaan die Grondslae van Koolstofveerkleed

Wat is koolstofdraadklere?

Koolstofveselklere steek uit as een van daardie gevorderde materiale wat gemaak word van koolstofvesels wat met spesiale polimeerhars gemeng word. Wanneer vervaardigers hierdie vesels saamweef en dit in hars week, skep hulle komposiete wat sterkte met verbasend lae gewig kombineer. Die vervaardiging van hierdie materiaal behels verskeie stappe, insluitend weefprosesse waar die veseloplyning baie belangrik is vir die verkryging van maksimum sterkte, asook stollingsfase wat alles op sy plek sit. Wat aan die einde daarvan uitkom, is eintlik weefsel met 'n paar ongelooflike eienskappe - lig genoeg om te hanteer, maar taai soos 'n spyker wanneer dit by trekragte kom en redelik styf ook. As gevolg van hierdie uitstekende balans tussen sterkte en gewig, koolstofvezel klaring het dit gewild geraak in baie nywe wat presteerdermateriale benodig, veral in die lugvaart- en motorbedrywe waar elke gram tel.

Gemeenskaplike Toepassings Oor Verskeie Bedrywe

Koolstofveselstof het baie gewild geraak in baie verskillende velde weens die eienskappe wat dit uniek maak. Die lugvaartbedryf gebruik dit wyd vir die vervaardiging van ligter komponente soos vleuels en die beweegbare vleueldele wat ailerons genoem word. Hierdie komponente help vliegtuie om brandstof te spaar terwyl hulle algehele beter vlieg. Motorvervaardigers verkies ook om met koolstofveselmateriaal te werk wanneer hulle hul voertuie wil laat vinniger beweeg of veiliger maak. Hulle gebruik dit vir dinge soos motorrame en die strukture binne-in waar sterkte die belangrikste is. Die vervaardigers van sporttoerusting is ook nie ver agter nie; dink aan tennisslae wat sterker gemaak word sonder om gewig te vermeerder. Selfs alledaagse items bevat nou koolstofveselmateriaal waar duursaamheid belangrik is. Ons sien ook dat die markte vinnig uitbrei. Al meer besighede klim op die koolstofvesel-trein toe, veral in die vliegtuig- en motorbedrywe, aangesien almal besef hoeveel beter die presteer wanneer dit van hierdie materiaal gemaak is. pRODUKTE presteer wanneer dit van hierdie materiaal gemaak is.

5 Kritieke Prestasie-Indikatoren vir Hoogkwaliteit Kohlefaser-Kleed

Trekhardheid en belastingsdra-vaardigheid

Wanneer 'n mens kyk na hoe materiale presteer onder spanning, speel treksterkte 'n groot rol, veral in dinge wat gewig moet dra. Basies vertel dit ons watter soort trek krag 'n materiaal kan hanteer voordat dit knap. Koolstofveselklere blink werklik uit in vergelyking met tradisionele metale soos aluminium of staal as gevolg van hul indrukwekkende treksterkte. Dit beteken dat onderdele wat van koolstofvesel gemaak is, sterk en duursaam bly, selfs wanneer dit aan swaar lasse onderwerp word. Neem die lugvaartbedryf as voorbeeld, waar vliegtuigkomponente geweldige kragte moet weerstaan tydens vlug. Op soortgelyke wyse vertrou motorvervaardigers op koolstofveselonderdele wat hul integriteit behou, ten spyte van konstante vibrasies en impakte. Laboratoriumtoetse oor die jare heen wys konsistens uit dat koolstofvesel ander materiale in spanningstoetse oortref. Daarom wend soveel ingenieurs hul tot koolstofvesel wanneer hulle iets nodig wat 'n kombinasie van ongelooflike sterkte en minimale gewig vereis.

Weefkonsistensie en Stofintegriteit

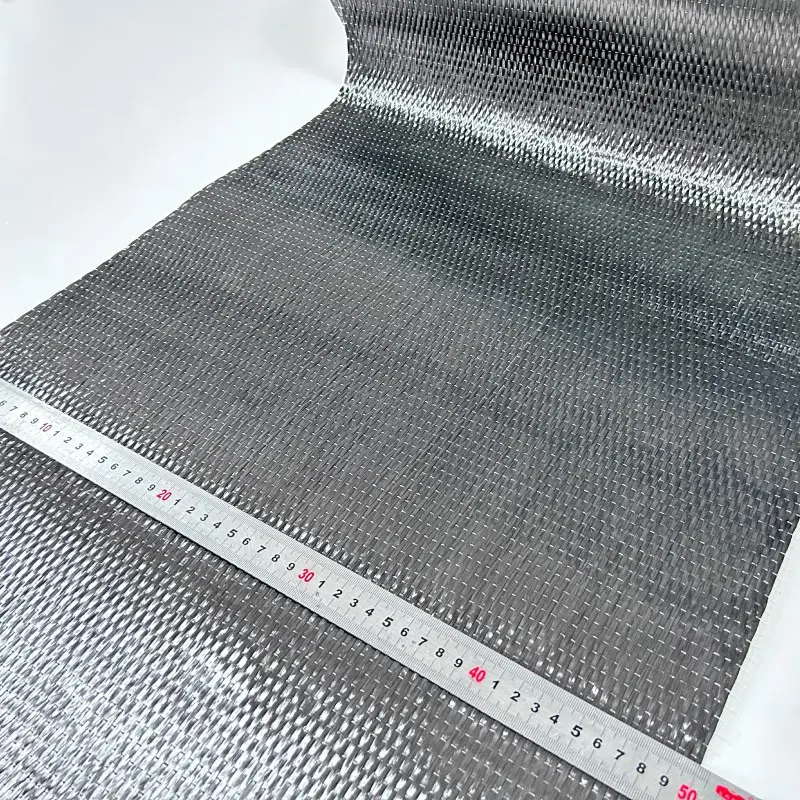

Gestadige weefwerk speel 'n sleutelrol in die handhaving van die strukturele sterkte van koolstofveselklere. Wanneer vesels eenvormig oor die materiaal geweef word, versprei hulle die sterkte gelykmatig deur die materiaal. Dit help om swak plekke te vermy wat andersins in kritieke areas kan voorkom. Swak weefwerk kan werklike probleemgebiede skep waar die materiaal nie so sterk is nie, wat veroorsaak dat komponente onder spanning faal of vroeër as verwagte uiteenval. Enigeen wat koolstofvesel koop, moet tyd spandeer om die weefpatroon van naby te ondersoek. Soek vir die regte sertifiseringsmerke wat bevestig dat die vervaardiger kwaliteitsstandaarde tydens produksie nagekom het. Vir sektore waar veiligheid van uiterste belang is, soos motorvervaardiging en vliegtuigbou, is dit absoluut noodsaaklik dat die weefpatrone gestadig is. Hierdie nywers moet verseker dat elke komponent betroubaar onder ekstreme toestande presteer sonder enige onaangename verrassings.

Kompatibiliteit met Koolstofvezelliem

Klime speel 'n regtig belangrike rol wanneer daar met koolstofvesel gewerk word, want dit bepaal eintlik hoe sterk en duursaam daardie gekleefde verbindings sal wees. Die regte tipe klimsel vir koolstofveselwerk te kies, is nie net iets om oor na te dink nie; dit is absoluut noodsaaklik as ons goeie binding in komposietmateriale wil hê. Daar is allerhande verskillende kliemselsoorte beskikbaar, elk met sy eie eienskappe. Sommige werk beter as ander, afhangend van die tipe omgewing waaraan hulle blootgestel word of die hoeveelheid stres wat hulle moet hanteer. Die regte klimsel by die spesifieke koolstofveselproduk pas, maak al die verskil in om goeie resultate te kry. Neem lugvaartkomponente as voorbeeld; hierdie komponente benodig dikwels spesiale kliemselsoorte wat 'n bietjie kan buig sonder om te breek, terwyl dit steeds uiterste temperature en vog kan weerstaan. Dit is dus hoekom dit so belangrik is om sorgvuldig te kies; dit is nie 'n geval van een grootte pas almal nie.

Optimale gewig-teen-sterkte-verhouding

Wanneer 'n mens kyk na hoe materiale presteer in verhouding tot hul gewig, steek koolstofvesel uit die massa uit. In vergelyking met ou vertroue soos glasvesel en verskeie metale, lewer koolstofvesel indrukwekkende sterkte terwyl dit goed lig op die skaal hou. Ons sien hierdie voordeel duidelik in werklike toepassings waar dit die meeste saak maak om gewig te verminder sonder om strukturele integriteit te kompromitteer. Dink aan voorbeelde soos vleuel van vliegtuie of raamwerke van renfietsen. Hoe ligter hierdie komponente is, hoe beter is hul algehele prestasie. Daar kom ook nog 'n ander voordeel by wat te min besproke is, naamlik energiebesparing oor die algemeen. Dit is hoekom soveel nywerhede wat gefokus is op om meer waarde vir hul geld te kry, oorskakel na koolstofveseloplossings wanneer hulle produkte ontwerp wat beide krag en doeltreffendheid benodig.

Omgewingstandvastigheid

Wanneer 'n mens kyk na hoe materiale hou in verskillende omgewings, veral goed soos koolstofveselklere, moet ons toets hoe hulle dit hanteer, soos sonbeskadiging, waterblootstelling en groot temperatuurswings. Poliëre-laagwerk kom uit bo meeste ander beskermende afwerwing omdat dit regtig beskerm teen moeilike omgewingsomstandighede. Hierdie lae help materiale om langer te hou sonder afbreek. Navorsing wys dat koolstofvesel baie beter werk wanneer dit gekombineer word met die regte soort laag. Die materiaal bly sterk selfs nadat dit aan rowwe behandeling oor tyd onderwerp is. Dit tel baie in sekere sektore waar onderdele gereeld aan brute toestande blootgestel word. Dink aan konstruksie terreine of boot op die oseaan. Sonder die regte beskerming sou hierdie komponente veel vroeër as verwagte misluk, probleme en ekstra koste veroorsaak.

Vergelyking tussen Koolstofvezelkleed en Plaat en Ander Komposiete

Verskille Tussen Koolstofvezelkleed en Koolstofvezelplaat

Koolstofveselklere en -plate speel verskillende maar verwante rolle in baie nywe industrieë as gevolg van hul samestelling. Koolstofveselklere bestaan uit gevlegte koolstofvesels wat dit opmerklik buigsaam maak en in staat stel om aan ingewikkelde vorms aan te pas. Dit maak dit veral geskik vir goed soos sporttoerusting waar komplekse krommes belangrik is, of motorinterieurpanele wat spesifieke kontoere moet volg. Terselfdertyd het koolstofveselplate 'n heel ander karakter. Hulle is baie stywer en vorm stewige, plat oppervlakke wat nodig is vir onderdele wat swaar lasse moet dra. Dink aan vliegtuigkomponente of fietsrame waar sterkte en styfheid van kritieke belang is. Die kontras tussen hierdie materiale wys waarom vervaardigers hulle dikwels in saamgestelde strukture kombineer vir optimale werkverrigting.

Koolstofveselklere werk baie goed wanneer dit gebruik word op gekromde oppervlaktes en komplekse vorms omdat dit so buigsaam is, terwyl die stywe aard van koolstofveselplate hulle beter geskik maak vir plat areas wat maksimum strukturele integriteit benodig. Neem fietskomponente as 'n voorbeeld: vervaardigers kies gewoonlik vir klere wanneer hulle aangepaste saals maak wat die vorm van die ruiter se liggaam volg, maar gebruik soliede plate vir dele van die raam wat intensiewe kragte moet hanteer tydens die ry. Dit is belangrik om hierdie verskil reg te kry wanneer jy die regte materiaal vir 'n spesifieke projek kies. Die meeste ingenieurs sal jou vertel dat die besluit gewoonlik daarop neerkom of hulle iets buigbaars of iets styfs nodig het vir die komponent waaraan hulle tans werk.

Rolle van liemmiddele in samegestelde stelsels

Dit is baie belangrik om die regte gom te kry wanneer daar met koolstofveselstof gewerk word in komposietsisteme, omdat dit direk beïnvloed hoe goed alles aanmekaar vashou. Wanneer 'n gom gekies word, kom verskeie aspekte in die oorweging in, soos of dit goed met die koolstofveselmateriaal werk, watter tipe bindingskrag nodig is vir die taak, watter soort omgewing die finale produk sal trotseer, en enige spesiale vereistes van die betrokke toepassing. Vir die meeste ernstige toepassings maak die gebruik van hoë-kwaliteit gomme 'n reuseverskil. Hierdie beter gomme skep sterker bindings wat langer hou onder spanning en hou die hele struktuur intact, selfs wanneer dit oor tyd aan harde toestande blootgestel word.

Die kies van die regte gom vir koolstofvesels saamgesteld uit verskeie sleutelaspekte soos die vinnigheid waarmee dit uithard, of dit hitte en chemikalieë kan weerstaan, en of dit goed met ander materiale in die mengsel werk. Die manier waarop ons hierdie komponente aan mekaar heg, is ook baie belangrik—oppervlakvoorbereiding en behoorlike uitharding maak 'n wêreld van verskil in hoe sterk en duursaam die eindproduk sal wees. Goeie gomme moet die werklike vereistes van die toepassing ontmoet. Dink aan waar dit gebruik sal word—buiteomstandighede teenoor beheerde omgewings, en hoeveel gewig of stres dit moet ondersteun. Sterk verbindings hou koolstofveselsamestellinge heel en behoorlik werkend, wat uiteindelik die hele struktuur sterker en betroubaarder maak in werklike toepassings.

Hoe om Kwaliteit te Verifieer Voordat Jy Koolstofvezelklote Koop

Onderhoud van Rol Uniformiteit

Wanneer jy koolstofveselstofrolle koop, is dit regtig belangrik om dit goed te bekyk voordat jy dit koop, om seker te maak dat jy 'n hoë kwaliteit produk kry. Die eerste ding om te toets? Kleurkonstansie oor die hele rol. Heldere, eenvormige kleur dui gewoonlik op beter kwaliteit materiaal, terwyl enigiets wat dof of vlekke het, dikwels wys op 'n laer gehalte produk. Dit is ook die moeite werd om die werklike afmetings te meet teenoor die wat op die verpakking aangedui word, aangesien verskille in grootte meer algemeen voorkom as wat mense besef. Gewigtoetse is ook belangrik, omdat beide die akkuraatheid van die afmetings en die korrekte gewig 'n direkte invloed het op hoe goed die stof in verskeie toepassings in die toekoms sal werk.

Hier is 'n paar lysse waaraan potensiële kopers aandag moet gee:

- Kleur en Heldering : Echte rolle lyk helder en het 'n konsekwente kleur.

- Tekstuur en Veerkragtigheid : Kontroleer die tekstuur; die stof moet sag voel, maar stevig, wat kwaliteit koolstofvezelmateriaal aandui.

- Rolafmetings en Gewig : Verseker dat afmetings presies volgens spesifikasies is vir suksesvolle implementering.

- Defekte en Foute : Soek na enige opvallende gebreke of onregmatighede.

Sommige hulpbronne vir toetsingsuitrusting of tegnieke kan insluit die gebruik van gespesialiseerde ligtemmers om kleurkonsekwensie te verifieer en weegskaalse vir presiese metings. Hierdie stappe kan kopers help om inferieure karbonveerkleedrolle te vermy.

Sleutelakkrediterings en Toetingsstandaarde

Verstaan akkrediterings en toetingsstandaarde is van lewensbelang om die kwaliteit van karbonveerkleed te verifieer en om die betroubaarheid en veiligheid van die materiaal te verseker. Akkrediterings soos ISO 9001 help verseker dat karbonveerkleed internasionale kwaliteitsbestuursstandaarde voldoen, wat robuuste vervaardigingsprosesse aandui.

Dit is baie belangrik om die regte sertifisering te kry, aangesien dit werklike vertroue bied oor hoe goed materiale presteer, hul duursaamheid oor tyd en hul veiligheid onder spanning. Dit word veral krities wanneer daar aan projekte gewerk word waar 'n fout kan lei tot ernstige probleme in die toekoms. Enige iemand wat materiale koop, moet kyk na dinge soos ASTM-sertifisering vir toetssprosedures. Sektor-spesifieke standaarde is ook belangrik, afhangende van die presiese gebruik van die materiaal. Byvoorbeeld, bou-spesifikasies verskil van dié wat in die lugvaartnywerheid gebruik word. Deur hierdie faktore in ag te neem, kan verseker word dat die aankope beide gehoor word aan gehaltesverwagtinge sowel as regulerende vereistes, sonder onnodige risiko's.

Hier is 'n paar aanbevelings oor watter sertifikate om na te soek:

- ISO 9001 : Sertifiseer kwaliteitsbestuursstelsels.

- ASTM Standaarde : Verseker kompliansie met spesifieke kwaliteit- en prestasie-norme.

- Bedryfsspesifieke Standaarde : Afhanklik van jou bedryf, kan spesifieke standaarde kompatibiliteit en prestasie verseker.

Deur aandag te skenk aan hierdie sertifikate, kan kopers selfvertrouer wees oor die sterkte en lewensduur van die karbonweefselrolle wat hulle koop.

Vrae wat dikwels gevra word

Wat maak karbonweefsel so gewild in hoë-prestasie toepassings?

Karbonweefsel word nagevra in hoë-prestasie toepassings weens sy ligwaterige aard, hoë treksterkte en uitstekende sterkte-gewig verhouding, wat die prestasie en doeltreffendheid van komponente oor verskeie bedrywe verbeter.

Waarom is weefkonsistensie belangrik in karbonweefsel?

Weefkonsistensie verseker dat karbonweefsel uniforme sterkte oor sy struktuur behou, swak plekke voorkom wat laai-vermoë kan kompromitteer en lei tot vroegtydige mislukking.

Hoe beïnvloed lijmstoffe die prestasie van koolstofvezelkomposiete?

Lijmstoffe bepaal die sterkte en duurzaamheid van voegsels in koolstofvezelkomposiete. Die keuse van die regte lijm op grond van die materiaal se eienskappe en omgewingsvoorwaardes is krities vir die versekering van langdurige prestasie en strukturele integriteit.

Wat is die voordele van koolstofvezelweefsel oor tradisionele materialen?

In vergelyking met tradisionele materialen soos aluminium of staal bied koolstofvezelweefsel superieure treksterkte, veerkrachtigheid en 'n beter gewig-teen-sterkte-verhouding, wat dit ideaal maak vir toepassings wat sowel sterkte as ligwaterigheidsvoordele vereis.

Hoe kan iemand die kwaliteit van koolstofvezelweefsel verifieer voordat hy dit koop?

Kwaliteit kan deur inspeksie vir rol uniformiteit, toets van kleur, tekstuur, afmetings, en deur soek na sertifikate soos ISO 9001 en ASTM-standaarde wat betroubare vervaardigingsprosesse en materiaalprestasie aandui, bevestig word.

Inhoudsopgawe

- Verstaan die Grondslae van Koolstofveerkleed

- 5 Kritieke Prestasie-Indikatoren vir Hoogkwaliteit Kohlefaser-Kleed

- Vergelyking tussen Koolstofvezelkleed en Plaat en Ander Komposiete

- Hoe om Kwaliteit te Verifieer Voordat Jy Koolstofvezelklote Koop

-

Vrae wat dikwels gevra word

- Wat maak karbonweefsel so gewild in hoë-prestasie toepassings?

- Waarom is weefkonsistensie belangrik in karbonweefsel?

- Hoe beïnvloed lijmstoffe die prestasie van koolstofvezelkomposiete?

- Wat is die voordele van koolstofvezelweefsel oor tradisionele materialen?

- Hoe kan iemand die kwaliteit van koolstofvezelweefsel verifieer voordat hy dit koop?