Entendendo os Fundamentos do Tecido de Fibra de Carbono

O que é Tecido de Fibra de Carbono?

O tecido de fibra de carbono destaca-se como um desses materiais avançados feitos a partir de fibras de carbono misturadas com resinas poliméricas especiais. Quando os fabricantes entrelaçam essas fibras e as imergem em resina, criam compósitos que combinam resistência com um peso surpreendentemente baixo. A produção desse material envolve várias etapas, incluindo processos de tecelagem onde o alinhamento das fibras é muito importante para obter a máxima resistência, além de estágios de cura que fixam tudo no lugar. O resultado final é basicamente um tecido com características impressionantes — leve o suficiente para ser manipulado, mas muito resistente quando submetido a forças de tração e bastante rígido também. Graças a esse excelente equilíbrio entre resistência e peso, tecido de fibra de carbono tornou-se popular em diversos setores industriais que necessitam de materiais de desempenho, especialmente na indústria aeroespacial e automotiva, onde cada grama conta.

Aplicações comuns em todos os setores

O tecido de fibra de carbono tornou-se bastante popular em diversas áreas devido às suas características especiais. O setor da aviação utiliza-o amplamente para a fabricação de peças mais leves, como os flaps e as asas móveis chamadas ailerons. Essas partes ajudam as aeronaves a economizar combustível enquanto melhoram o desempenho geral. Os fabricantes de automóveis também adoram trabalhar com materiais de fibra de carbono quando desejam que seus veículos sejam mais rápidos ou seguros. Eles utilizam esse material em componentes como a carroceria e estruturas internas, onde a resistência é essencial. Os produtores de equipamentos esportivos também estão na corrida: pense em raquetes de tênis mais resistentes sem aumento de peso. Até mesmo itens do dia a dia agora incorporam materiais de fibra de carbono em situações onde a durabilidade é importante. Estamos vendo os mercados se expandirem rapidamente nos últimos tempos. Cada vez mais empresas estão adotando soluções com fibra de carbono, especialmente em aeronaves e automóveis, já que todos parecem reconhecer o quanto essas peças se tornam melhores feitas com esse material. produtos desempenho quando fabricadas com esse material.

5 Indicadores Críticos de Desempenho para Tecido de Fibra de Carbono de Alta Qualidade

Resistência à Tração e Capacidade de Suporte de Carga

Ao analisar o desempenho dos materiais sob tensão, a resistência à tração desempenha um papel fundamental, especialmente em estruturas que precisam suportar peso. Basicamente, ela indica qual tipo de força de puxão um material consegue suportar antes de se romper. O tecido de fibra de carbono se destaca bastante em comparação com metais tradicionais, como alumínio ou aço, graças à sua impressionante resistência à tração. Isso significa que peças fabricadas em fibra de carbono permanecem resistentes e duráveis, mesmo quando submetidas a cargas pesadas. Tome como exemplo a indústria aeroespacial, onde componentes de aeronaves precisam suportar forças imensas durante o voo. Da mesma forma, fabricantes de automóveis contam com peças de fibra de carbono que mantêm sua integridade apesar das vibrações constantes e impactos. Testes em laboratório ao longo dos anos mostram consistentemente que a fibra de carbono supera outros materiais nos testes de tração. É por isso que muitos engenheiros recorrem à fibra de carbono quando precisam de algo que combine uma força incrível com requisitos mínimos de peso.

Consistência do Tecido e Integridade do Pano

Uma tecelagem consistente desempenha um papel fundamental na manutenção da integridade estrutural do tecido de fibra de carbono. Quando as fibras são tecidas uniformemente ao longo do material, elas distribuem a resistência de maneira equilibrada em toda sua extensão. Isso ajuda a evitar pontos fracos que poderiam surgir em áreas críticas. Uma tecelagem inadequada pode criar zonas problemáticas onde o material não é tão resistente, resultando em peças que falhem sob tensão ou se desgastem mais rapidamente do que o esperado. Qualquer pessoa que compre fibra de carbono deve dedicar tempo para examinar de perto o aspecto do tecido. Procure por marcas de certificação adequadas que garantam que o fabricante seguiu padrões de qualidade durante a produção. Em setores onde a segurança é prioritária, como na indústria automotiva e na construção aeronáutica, ter padrões uniformes na tecelagem é absolutamente essencial. Essas indústrias necessitam que cada componente funcione com confiabilidade sob condições extremas, sem imprevistos.

Compatibilidade com Adesivo de Fibra de Carbono

Adesivos desempenham um papel realmente importante ao trabalhar com fibra de carbono, pois basicamente determinam quão resistentes e duráveis serão essas juntas coladas. Escolher o tipo correto de adesivo para trabalhos com fibra de carbono não é apenas algo a se considerar, é absolutamente necessário se quisermos uma boa adesão em materiais compostos. Existem todos os tipos de adesivos por aí, cada um com suas próprias características. Alguns têm desempenho superior a outros, dependendo do tipo de ambiente a que forem expostos ou do nível de tensão que precisarem suportar. Associar o adesivo certo ao produto específico de fibra de carbono faz toda a diferença para obter resultados decentes. Tome como exemplo componentes aeroespaciais, que frequentemente necessitam de adesivos especiais capazes de flexionar um pouco sem quebrar, mantendo-se resistentes a temperaturas extremas e à umidade. Por isso a seleção cuidadosa é tão importante — não se trata de uma solução única válida para todos os casos.

Relação Peso-Resistência Ótima

Ao analisar o desempenho dos materiais em relação ao seu peso, as fibras de carbono se destacam claramente. Em comparação com materiais tradicionais, como fibra de vidro e diversos metais, a fibra de carbono oferece uma resistência impressionante mantendo um peso reduzido. Essa vantagem é claramente visível em aplicações práticas, onde a redução de peso é essencial sem comprometer a integridade estrutural. Considere, por exemplo, as asas de aviões ou os quadros de bicicletas de corrida. Quanto mais leves forem essas peças, melhor será o desempenho geral. Além disso, há outro benefício que raramente é mencionado: economia de energia generalizada. É por isso que tantas indústrias que buscam obter mais eficiência estão adotando soluções em fibra de carbono ao projetar produtos que exigem potência e eficiência.

Durabilidade Ambiental

Ao analisar como os materiais resistem em diferentes ambientes, especialmente coisas como tecido de fibra de carbono, é necessário verificar como eles suportam danos causados pelo sol, exposição à água e grandes variações de temperatura. Os revestimentos de poliureia se destacam em comparação com a maioria dos outros acabamentos protetores, pois oferecem uma proteção eficaz contra condições ambientais adversas. Esses revestimentos ajudam os materiais a durarem mais sem se degradarem. Pesquisas mostram que a fibra de carbono funciona muito melhor quando combinada com o tipo adequado de revestimento. O material permanece forte mesmo após ser submetido a condições rigorosas ao longo do tempo. Isso é extremamente relevante em certos setores onde peças estão regularmente expostas a condições severas. Pense em canteiros de obras ou embarcações no oceano. Sem proteção adequada, esses componentes falhariam muito mais cedo do que o esperado, causando problemas e custos adicionais no futuro.

Comparando Tecido de Fibra de Carbono com Placas e Outros Compostos

Diferenças entre Tecido de Fibra de Carbono e Placas de Fibra de Carbono

Tecidos e placas de fibra de carbono desempenham papéis distintos, mas relacionados, em diversas indústrias, devido à forma como são construídos. O tecido de fibra de carbono é composto por fibras de carbono entrelaçadas, o que lhe confere flexibilidade notável e a capacidade de se adaptar a formas complexas. Isso o torna especialmente adequado para itens como equipamentos esportivos, onde curvas complexas são importantes, ou painéis internos de carros que precisam se ajustar a contornos específicos. Por outro lado, as placas de fibra de carbono possuem um caráter completamente diferente. Elas são muito mais rígidas e formam superfícies planas sólidas, necessárias para peças que devem suportar cargas pesadas. Considere componentes de aviões ou quadros de bicicletas, onde resistência e rigidez são absolutamente críticas. O contraste entre esses materiais destaca o motivo pelo qual os fabricantes frequentemente os combinam em estruturas compostas para obter um desempenho ideal.

O tecido de fibra de carbono funciona muito bem ao lidar com superfícies curvas e formas complexas, graças à sua grande flexibilidade, enquanto a natureza rígida das placas de fibra de carbono as torna mais adequadas para áreas planas que exigem máxima integridade estrutural. Tome como exemplo os componentes de bicicletas: os fabricantes geralmente optam pelo tecido ao produzir selins sob medida que se adaptam ao corpo dos ciclistas, mas utilizam placas sólidas para partes do quadro que precisam suportar forças intensas durante o uso. Compreender essa diferença é muito importante ao escolher materiais para projetos específicos. A maioria dos engenheiros dirá que a decisão normalmente se resume a saber se é necessário um material flexível ou rígido para a peça em questão.

Papel dos Adesivos em Sistemas Compostos

Escolher o adesivo correto é muito importante ao trabalhar com tecido de fibra de carbono em sistemas compostos, pois isso afeta diretamente a eficiência da união dos materiais. Na seleção de um adesivo, diversos fatores entram em consideração, como a sua compatibilidade com o material de fibra de carbono, o nível de resistência da união necessário para a aplicação em questão, o tipo de ambiente ao qual o produto final será exposto, além de possíveis requisitos específicos da aplicação. Para a maioria das aplicações mais exigentes, optar por adesivos de alta qualidade faz toda a diferença. Esses adesivos de melhor qualidade criam ligações mais fortes, que resistem por mais tempo sob esforço, mantendo toda a estrutura intacta, mesmo quando submetida a condições adversas ao longo do tempo.

Escolher o adesivo certo para compósitos de fibra de carbono envolve analisar diversos aspectos importantes, como a velocidade de cura, se é capaz de resistir ao calor e a produtos químicos e se apresenta compatibilidade com outros materiais na mistura. O método utilizado para unir esses componentes também é muito relevante – o preparo da superfície e a cura adequada fazem toda a diferença quanto à resistência e durabilidade do produto final. Os bons adesivos devem atender às exigências reais da aplicação. Considere onde serão utilizados: em ambientes externos ou controlados, e quanto peso ou estresse precisam suportar. Ligações resistentes mantêm os compósitos de fibra de carbono intactos e funcionando corretamente, tornando toda a estrutura mais forte e confiável em situações reais.

Como Verificar a Qualidade Antes de Comprar Rolos de Tecido de Fibra de Carbono

Inspeção da Uniformidade do Rolo

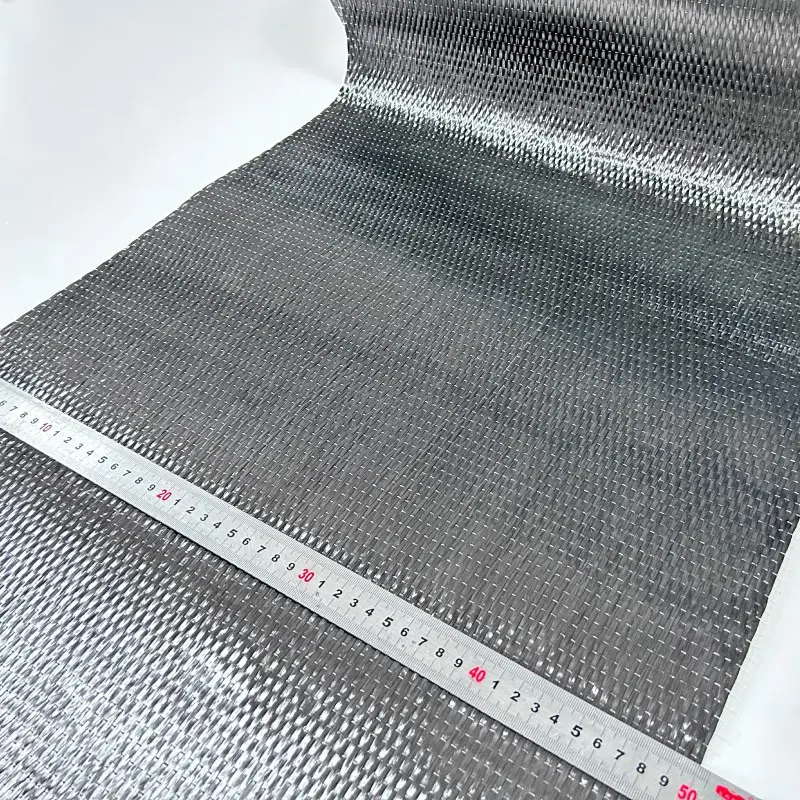

Ao comprar rolos de tecido de fibra de carbono, examiná-los cuidadosamente antes da compra é essencial para garantir a qualidade do material. A primeira coisa a verificar? A consistência da cor em todo o rolo. Cores brilhantes e uniformes geralmente indicam material de melhor qualidade, enquanto cores opacas ou irregulares costumam apontar para produtos de qualidade inferior. Também é importante medir as dimensões reais e compará-las com as listadas na embalagem, já que discrepâncias de tamanho ocorrem com mais frequência do que as pessoas imaginam. A verificação do peso também é relevante, pois tanto a precisão das dimensões quanto o peso adequado afetam diretamente o desempenho do tecido em diversas aplicações futuras.

Aqui estão algumas listas de verificação que compradores potenciais devem considerar:

- Cor e Brilho : Rolos genuínos parecem brilhantes e têm uma cor consistente.

- Textura e Flexibilidade : Verifique a textura; o tecido deve se sentir macio, mas forte, indicando materiais de fibra de carbono de qualidade.

- Dimensões e Peso da Bobina : Garanta que as dimensões estejam precisas conforme as especificações para uma implantação bem-sucedida.

- Defeitos e Falhas : Procure por qualquer imperfeição ou inconsistência visível.

Alguns recursos para testar equipamentos ou técnicas podem incluir o uso de medidores de luz especializados para verificar a consistência de cor e balanças para medições precisas. Esses passos podem ajudar os compradores a evitar a compra de rolos de tecido de fibra de carbono de qualidade inferior.

Certificações e Padrões de Teste Chave

Entender certificações e padrões de teste é vital para verificar a qualidade do tecido de fibra de carbono e garantir a confiabilidade e segurança do material. Certificações como ISO 9001 ajudam a garantir que o tecido de fibra de carbono atenda aos padrões internacionais de gestão de qualidade, indicando processos de fabricação sólidos.

Obter as certificações adequadas é muito importante, já que elas transmitem confiança real em relação ao desempenho dos materiais, à durabilidade ao longo do tempo e à segurança sob tensão. Isso torna-se especialmente crítico ao trabalhar em projetos onde algo saindo do controle possa causar problemas sérios no futuro. Qualquer pessoa que compre materiais precisa verificar itens como a certificação ASTM para procedimentos de teste. Também são importantes os padrões específicos da indústria, dependendo do uso exato que será feito do material. Por exemplo, as especificações para construção diferem daquelas utilizadas na fabricação aeroespacial. Levar esses fatores em conta ajuda a garantir que o que for comprado atenda tanto às expectativas de qualidade quanto aos requisitos regulatórios, sem envolver riscos desnecessários.

Aqui estão algumas recomendações sobre quais certificações procurar:

- ISO 9001 : Certifica sistemas de gestão da qualidade.

- Padrões ASTM : Garante conformidade com benchmarks específicos de qualidade e desempenho.

- Padrões específicos do setor : Dependendo do seu setor, padrões específicos podem garantir compatibilidade e desempenho.

Ao prestar atenção a essas certificações, os compradores podem ter mais confiança na resistência e durabilidade das bobinas de tecido de fibra de carbono que adquirem.

Perguntas frequentes

O que torna o tecido de fibra de carbono desejável em aplicações de alto desempenho?

O tecido de fibra de carbono é procurado em aplicações de alto desempenho devido à sua natureza leve, alta resistência à tração e excelente relação força-peso, que melhoram o desempenho e a eficiência dos componentes em várias indústrias.

Por que a consistência do entrelaçamento é importante no tecido de fibra de carbono?

A consistência do entrelaçamento garante que o tecido de fibra de carbono mantenha uma força uniforme em sua estrutura, evitando pontos fracos que poderiam comprometer a capacidade de carga e levar a falhas prematuras.

Como os adesivos afetam o desempenho de compostos de fibra de carbono?

Adesivos determinam a força e durabilidade das junções em compostos de fibra de carbono. Escolher o adesivo certo com base nas propriedades do material e nas condições ambientais é crucial para garantir um desempenho de longa duração e integridade estrutural.

Quais são as vantagens do tecido de fibra de carbono sobre materiais tradicionais?

Em comparação com materiais tradicionais como alumínio ou aço, o tecido de fibra de carbono oferece uma força de tração superior, flexibilidade e uma melhor relação peso-resistência, tornando-o ideal para aplicações que exigem tanto força quanto benefícios leves.

Como alguém pode verificar a qualidade do tecido de fibra de carbono antes de comprar?

A qualidade pode ser verificada inspecionando a uniformidade da bobina, conferindo cor, textura, dimensões e procurando certificações como ISO 9001 e normas ASTM que indicam processos de fabricação confiáveis e desempenho do material.

Sumário

- Entendendo os Fundamentos do Tecido de Fibra de Carbono

- 5 Indicadores Críticos de Desempenho para Tecido de Fibra de Carbono de Alta Qualidade

- Comparando Tecido de Fibra de Carbono com Placas e Outros Compostos

- Como Verificar a Qualidade Antes de Comprar Rolos de Tecido de Fibra de Carbono

-

Perguntas frequentes

- O que torna o tecido de fibra de carbono desejável em aplicações de alto desempenho?

- Por que a consistência do entrelaçamento é importante no tecido de fibra de carbono?

- Como os adesivos afetam o desempenho de compostos de fibra de carbono?

- Quais são as vantagens do tecido de fibra de carbono sobre materiais tradicionais?

- Como alguém pode verificar a qualidade do tecido de fibra de carbono antes de comprar?