chemical anchor fastener hilti

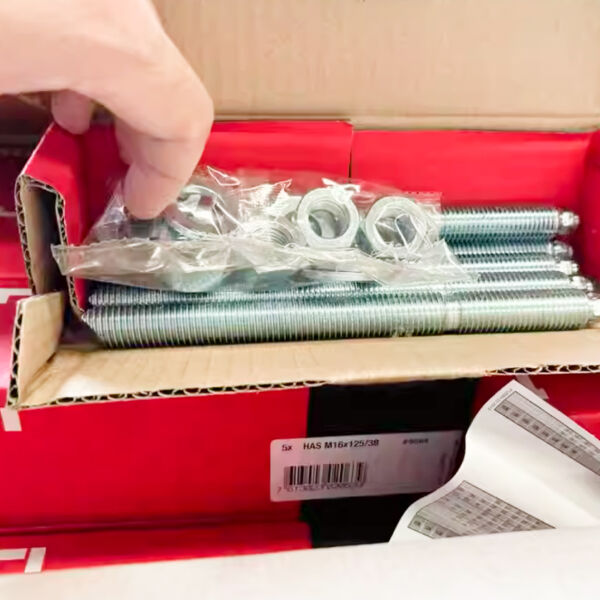

The chemical anchor fastener Hilti represents a cutting-edge solution in construction and industrial fastening technology. This advanced anchoring system combines high-performance epoxy resins with precisely engineered components to create exceptionally strong and reliable connections in various base materials. The system works by utilizing a two-component adhesive that, when mixed, creates a powerful chemical bond between the anchor rod and the base material. The chemical anchor fastener Hilti is specifically designed to provide superior performance in both cracked and non-cracked concrete, making it ideal for heavy-duty applications. The system features controlled cure times and can be used in a wide range of temperatures, ensuring optimal installation flexibility. What sets this system apart is its ability to distribute loads evenly throughout the base material, reducing stress concentrations and enhancing overall structural integrity. The chemical anchor can be used with various anchor rod sizes and materials, including stainless steel and hot-dip galvanized options, offering versatility for different project requirements. Its advanced formulation provides excellent resistance to chemicals, weathering, and temperature variations, ensuring long-term durability and reliability in demanding environments.