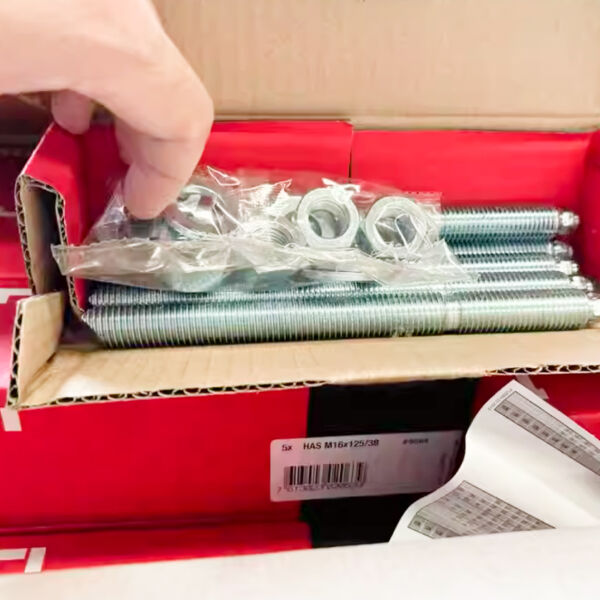

hilti chemical bolt m16

The Hilti Chemical Bolt M16 represents a cutting-edge anchoring solution designed for heavy-duty structural applications. This advanced fastening system combines a high-strength steel bolt with specialized chemical adhesive technology to create exceptional bond strength in various base materials. The M16 size offers optimal load-bearing capacity for medium to large-scale installations, making it particularly suitable for structural connections, industrial equipment mounting, and heavy machinery installations. The system consists of a threaded rod manufactured from premium-grade steel, paired with Hilti's proprietary chemical adhesive formulation that ensures superior performance even in challenging environmental conditions. The chemical anchoring technology creates a void-free bond with the base material, effectively distributing loads and minimizing stress concentrations. With its precise engineering and robust design, the Hilti Chemical Bolt M16 provides outstanding resistance to dynamic loads, vibrations, and seismic forces, while maintaining exceptional pull-out strength and shear resistance. The system is ETA approved and complies with international building codes and standards, ensuring reliability and safety in critical applications.