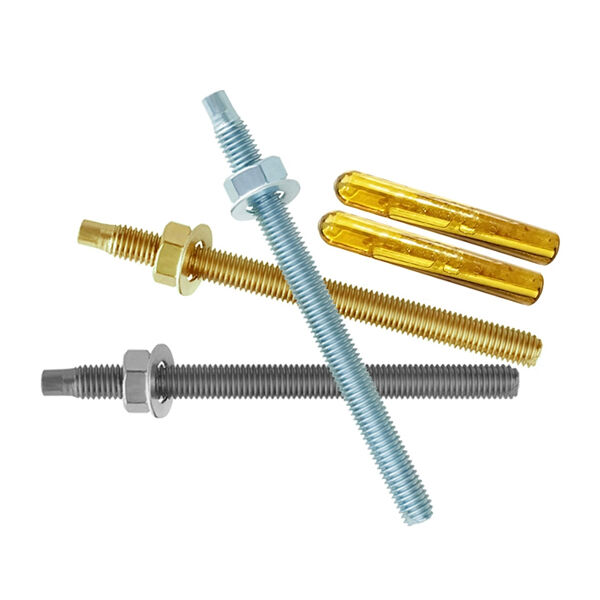

fan anchor bolt

A fan anchor bolt is a specialized fastening device designed specifically for securing industrial fans, HVAC equipment, and heavy machinery to various mounting surfaces. These high-strength components combine the reliability of traditional anchor bolts with unique features tailored for vibration-intensive applications. The bolt consists of a threaded shaft, an expansion mechanism, and a specially designed head that provides optimal load distribution. Fan anchor bolts are manufactured from premium-grade steel, often featuring corrosion-resistant coatings to ensure longevity in demanding environments. They employ a dual-action securing mechanism that provides both vertical and lateral stability, crucial for equipment that generates continuous vibration. The design incorporates advanced threading patterns that maintain grip integrity even under constant motion, while the expansion section creates a robust connection with the mounting surface. These bolts are available in various sizes and configurations to accommodate different load requirements and installation scenarios, making them versatile solutions for both industrial and commercial applications. The engineering behind fan anchor bolts prioritizes safety and reliability, incorporating features like stress-distribution channels and precision-machined surfaces that enhance overall performance and longevity.