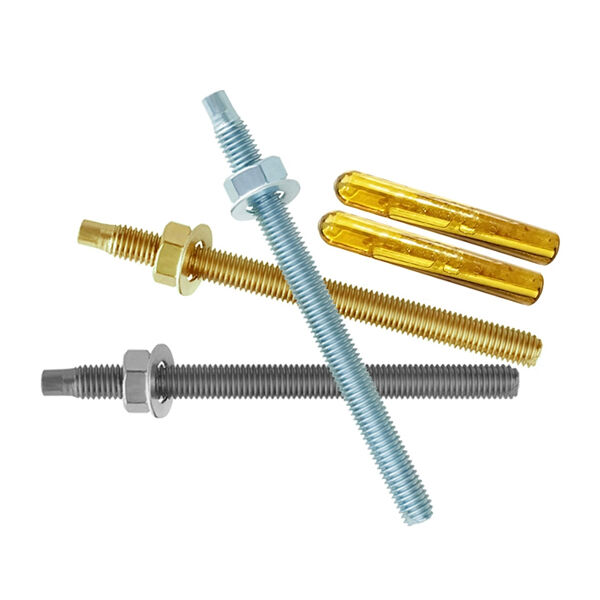

resin anchor bolts

Resin anchor bolts represent a cutting-edge fastening solution that combines chemical adhesion with mechanical strength to create superior anchoring in various construction materials. These innovative fasteners consist of a threaded rod or bolt that works in conjunction with a specialized resin compound, typically a two-component epoxy or polyester resin system. When installed, the resin fills the annular space between the bolt and the base material, creating a robust chemical bond that distributes loads evenly throughout the connection. The installation process involves drilling a hole, cleaning it thoroughly, injecting the resin, and inserting the anchor bolt. The resin then cures, forming a solid matrix that securely holds the bolt in place. These anchors excel in applications requiring high load capacity, resistance to vibration, and superior performance in both cracked and uncracked concrete. They are particularly valuable in structural engineering projects, heavy machinery mounting, and scenarios where traditional mechanical anchors might not provide adequate support. The versatility of resin anchor bolts extends to their ability to perform effectively in various environmental conditions, including underwater applications and exposure to chemical agents.