Revolutionizing Industrial Applications with Advanced Composite Materials

The industrial landscape is experiencing a remarkable transformation with the widespread adoption of carbon fiber mesh cloth across various sectors. This versatile material, characterized by its exceptional strength-to-weight ratio and durability, is reshaping manufacturing processes and enabling groundbreaking innovations. As industries continue to seek lighter, stronger, and more sustainable materials, carbon fiber mesh cloth has emerged as a game-changing solution that combines cutting-edge technology with practical applications.

Understanding Carbon Fiber Mesh Cloth Technology

Composition and Manufacturing Process

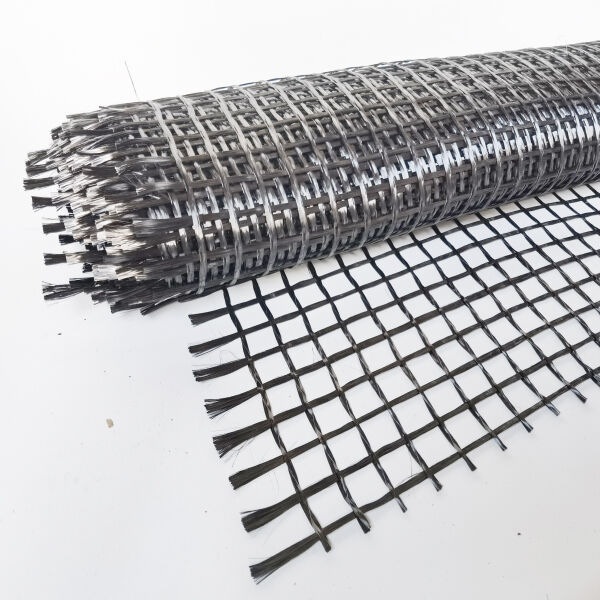

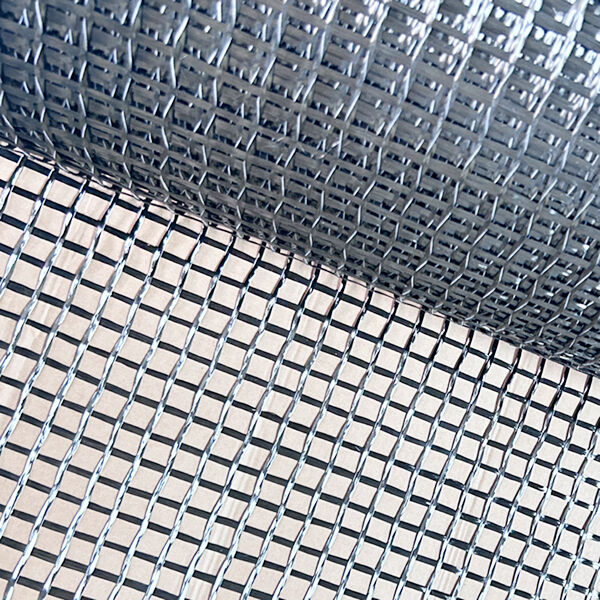

Carbon fiber mesh cloth consists of interwoven carbon fiber strands arranged in a precise grid pattern. The manufacturing process begins with the creation of carbon fiber filaments through the carbonization of organic precursor materials, typically polyacrylonitrile (PAN). These filaments are then woven into a mesh structure, creating a material that combines flexibility with extraordinary strength. The resulting cloth features uniform spacing between fibers, allowing for consistent performance across its entire surface area.

The weaving patterns and fiber density can be customized to meet specific application requirements. Manufacturers can adjust the mesh size, fiber thickness, and weave configuration to optimize the material's properties for particular uses. This versatility in production enables carbon fiber mesh cloth to serve diverse industrial needs effectively.

Key Material Properties and Advantages

The exceptional characteristics of carbon fiber mesh cloth make it an ideal choice for demanding industrial applications. Its outstanding strength-to-weight ratio surpasses traditional materials like steel and aluminum, while maintaining remarkable flexibility and dimensional stability. The material exhibits excellent resistance to corrosion, chemicals, and environmental factors, ensuring long-term performance in challenging conditions.

Furthermore, carbon fiber mesh cloth demonstrates superior thermal conductivity and electromagnetic shielding properties. These attributes, combined with its natural resistance to fatigue and wear, make it particularly valuable in applications requiring durability and reliable performance under stress.

Industrial Applications and Implementation

Aerospace and Aviation Solutions

The aerospace industry has embraced carbon fiber mesh cloth as a crucial component in aircraft construction and maintenance. Its lightweight nature contributes significantly to fuel efficiency, while its strength ensures structural integrity. Aircraft manufacturers utilize this material in wing components, fuselage reinforcement, and interior structures, achieving substantial weight reduction without compromising safety standards.

Modern spacecraft and satellite designs also incorporate carbon fiber mesh cloth in thermal protection systems and structural reinforcement. The material's ability to withstand extreme temperature variations and maintain stability in space environments makes it invaluable for aerospace applications.

Construction and Infrastructure Enhancement

In the construction sector, carbon fiber mesh cloth has revolutionized structural reinforcement techniques. Engineers employ this material for concrete strengthening, seismic retrofitting, and bridge rehabilitation projects. The cloth's high tensile strength and corrosion resistance provide superior alternatives to traditional steel reinforcement, extending the lifespan of infrastructure while reducing maintenance requirements.

Modern architectural designs increasingly feature carbon fiber mesh cloth in innovative ways, from lightweight facade elements to structural supports in high-rise buildings. The material's versatility allows architects to create bold, sustainable structures while meeting strict building codes and safety requirements.

Environmental Impact and Sustainability

Lifecycle Assessment and Carbon Footprint

While the production of carbon fiber mesh cloth requires significant energy input, its long-term environmental benefits often outweigh initial manufacturing impacts. The material's durability and resistance to degradation result in fewer replacement cycles, reducing overall resource consumption. Additionally, its lightweight properties contribute to reduced fuel consumption in transportation applications, leading to lower carbon emissions throughout its service life.

Manufacturers are continuously developing more sustainable production methods, including the use of renewable energy sources and recycled materials in the manufacturing process. These initiatives are gradually reducing the environmental impact of carbon fiber mesh cloth production while maintaining its superior performance characteristics.

Recycling and Material Recovery

The industry is making significant strides in developing effective recycling methods for carbon fiber mesh cloth. Advanced recycling technologies can recover valuable carbon fibers from end-of-life products, which can be repurposed for various applications. This circular approach to material management helps minimize waste and supports sustainable industrial practices.

Research institutions and manufacturers are collaborating to improve recycling efficiency and develop new applications for recycled carbon fiber materials. These efforts are crucial for establishing a more sustainable lifecycle for carbon fiber mesh cloth products.

Future Trends and Innovations

Advanced Manufacturing Technologies

The future of carbon fiber mesh cloth production is being shaped by emerging technologies such as automated fiber placement and advanced weaving techniques. These innovations promise to improve manufacturing efficiency while enabling more complex mesh patterns and specialized material properties. Integration of smart manufacturing principles and Industry 4.0 technologies is expected to further optimize production processes.

Research into nano-enhanced carbon fibers and hybrid mesh materials continues to push the boundaries of material performance. These developments may lead to next-generation products with enhanced strength, conductivity, and functionality.

Emerging Applications and Market Growth

New applications for carbon fiber mesh cloth continue to emerge across various industries. The renewable energy sector is exploring its use in wind turbine blades and solar panel supports, while the automotive industry is increasing its implementation in lightweight vehicle components. Medical technology applications are also expanding, particularly in prosthetics and rehabilitation equipment.

Market analysts project sustained growth in the carbon fiber mesh cloth industry, driven by increasing demand for high-performance materials and growing awareness of sustainability benefits. This growth is expected to accelerate as manufacturing costs decrease and new applications are developed.

Frequently Asked Questions

How does carbon fiber mesh cloth compare to traditional materials in terms of strength and durability?

Carbon fiber mesh cloth typically offers superior strength-to-weight ratios compared to traditional materials like steel and aluminum. It demonstrates exceptional durability, resistance to fatigue, and minimal degradation over time, often outlasting conventional materials in demanding applications while maintaining its structural integrity.

What are the primary considerations when selecting carbon fiber mesh cloth for specific applications?

Key factors include the required strength characteristics, environmental conditions, load requirements, and cost considerations. Engineers must also consider mesh size, fiber orientation, and surface treatment options to ensure optimal performance for the intended application. Consultation with material specialists is recommended for proper selection.

Can carbon fiber mesh cloth be recycled or repurposed at the end of its life cycle?

Yes, carbon fiber mesh cloth can be recycled through specialized processes that recover the carbon fibers for reuse in various applications. While recycling technologies continue to evolve, current methods can successfully reclaim valuable materials, contributing to more sustainable industrial practices and circular economy initiatives.