Innovation in Aerospace Materials: Combining Lightweight and High Performance

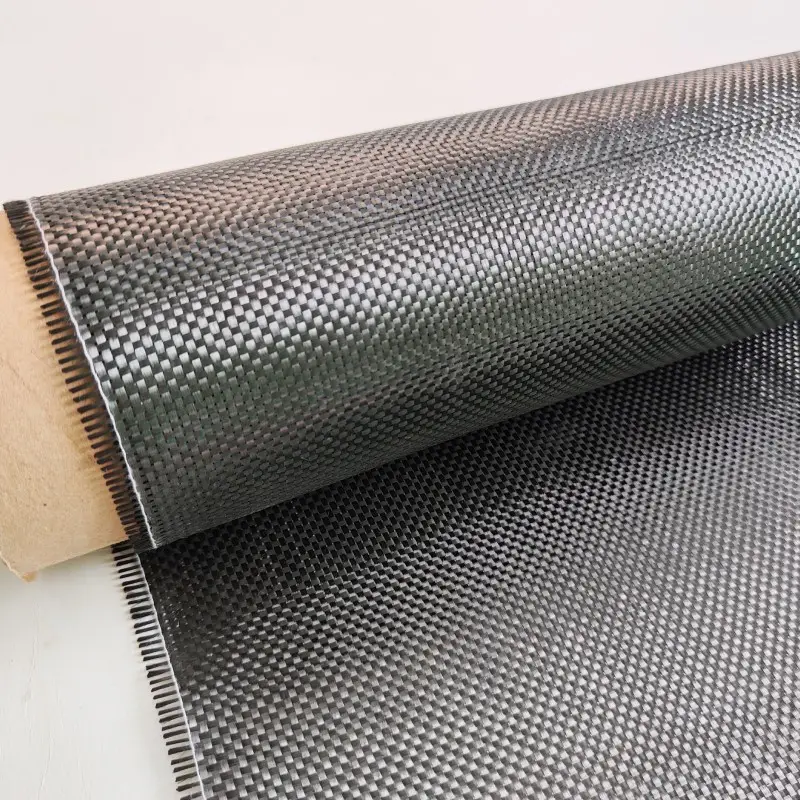

In the modern aerospace industry, material selection plays a crucial role in determining aircraft performance. As the demand for lightweight and high-strength components increases, traditional metal materials often struggle to meet the complex design and performance requirements of advanced aircraft. Carbon Fiber Bidirectional Fabric has emerged as a leading solution in aerospace manufacturing due to its exceptional strength, durability, and versatility. This article explores the applications of Carbon Fiber Bidirectional Fabric in aerospace and highlights the numerous advantages it brings to the industry.

Material Properties and Performance Advantages

High Strength and Lightweight

Carbon Fiber Bidirectional Fabric offers an excellent strength-to-weight ratio, making it ideal for aerospace structures where reducing overall weight is critical. Compared to conventional aluminum alloys, Carbon Fiber Bidirectional Fabric not only provides superior strength but also demonstrates remarkable toughness. Engineers can strategically orient the fibers in multiple directions to optimize load-bearing capacity while maintaining a lightweight design. This combination of properties enables enhanced fuel efficiency, improved payload capacity, and greater overall aircraft performance.

Exceptional Fatigue Resistance

Aircraft components experience repeated stress cycles during flight, which demands materials with outstanding fatigue resistance. Carbon Fiber Bidirectional Fabric maintains its integrity under multidirectional stress without significant crack propagation. This ensures that wings, fuselage frames, and other critical structures can achieve longer service life and require less maintenance. The durability of Carbon Fiber Bidirectional Fabric under cyclic loading conditions makes it a reliable choice for critical aerospace applications.

Manufacturing Flexibility and Design Versatility

Multidirectional Load-Bearing Capability

The bidirectional weave of Carbon Fiber Bidirectional Fabric provides aerospace designers with increased flexibility in structural optimization. Fibers aligned in different directions can be tailored to match the specific load paths of components, enhancing overall structural stability and safety. This property is particularly beneficial for complex curves and asymmetrical geometries, enabling innovative aircraft designs without compromising strength or safety.

Ease of Composite Fabrication

Carbon Fiber Bidirectional Fabric integrates seamlessly with resin systems, offering excellent wet-out and forming characteristics. Whether using hand lay-up, vacuum bag molding, or automated fiber placement techniques, this material ensures uniform distribution and minimizes voids or defects. The excellent processability of Carbon Fiber Bidirectional Fabric not only improves manufacturing efficiency but also guarantees consistent mechanical performance and structural reliability in the final product.

Thermal Performance and Environmental Resistance

Outstanding High-Temperature Resistance

Aircraft operate under extreme temperature variations at high altitudes. Carbon Fiber Bidirectional Fabric exhibits remarkable thermal stability, maintaining structural integrity even in high-temperature environments. Components located near engines or exposed to direct sunlight on the aircraft surface retain their mechanical properties without warping or degradation. This heat resistance makes Carbon Fiber Bidirectional Fabric suitable for applications that demand both performance and safety under thermal stress.

Corrosion and Chemical Resistance

One of the challenges in aerospace materials is exposure to harsh environmental conditions, including moisture, UV radiation, and chemicals. Carbon Fiber Bidirectional Fabric resists corrosion and chemical degradation, unlike many traditional metallic materials. This resistance contributes to longer service life, reduced maintenance costs, and greater overall reliability of aircraft components. Its ability to withstand environmental stressors makes it ideal for structural panels, control surfaces, and other aerospace parts that face demanding conditions.

Mechanical Advantages in Aerospace Applications

High Stiffness and Dimensional Stability

A key advantage of Carbon Fiber Bidirectional Fabric is its high stiffness, which ensures dimensional stability under load. Aerospace components made from this fabric exhibit minimal deformation, even under extreme forces encountered during flight maneuvers. The predictable mechanical behavior of Carbon Fiber Bidirectional Fabric allows engineers to design more precise structures and maintain aerodynamic efficiency.

Energy Absorption and Impact Resistance

Aircraft safety requires materials that can absorb energy and resist impact effectively. Carbon Fiber Bidirectional Fabric demonstrates excellent energy absorption capacity while maintaining structural integrity under impact. This property is crucial for components such as leading edges, fuselage sections, and internal structural supports, where both safety and performance are paramount.

Cost Efficiency and Lifecycle Benefits

Reduced Maintenance and Lifecycle Costs

While the initial cost of Carbon Fiber Bidirectional Fabric may be higher than traditional metals, its superior durability and reduced maintenance needs translate to long-term cost savings. Components made from this fabric require fewer repairs, have longer service intervals, and can extend overall aircraft lifespan. This lifecycle advantage makes it an economically viable choice for commercial and military aerospace applications.

Weight Reduction and Fuel Efficiency

The lightweight nature of Carbon Fiber Bidirectional Fabric contributes to significant fuel savings over an aircraft's operational life. Reducing weight lowers fuel consumption, enhances payload capacity, and minimizes environmental impact. Airlines and manufacturers benefit from improved operational efficiency and reduced carbon emissions, making Carbon Fiber Bidirectional Fabric an environmentally and economically strategic material choice.

Aerospace Design Applications

Structural Components

Carbon Fiber Bidirectional Fabric is widely used in primary and secondary structural components. From wing spars and fuselage frames to interior panels, its high strength and stiffness ensure reliable performance under flight loads. Engineers often choose this fabric for critical areas where weight savings and mechanical properties are essential.

Non-Structural and Interior Applications

Beyond structural components, Carbon Fiber Bidirectional Fabric finds applications in non-structural and interior parts, such as cabin panels, flooring, and cargo areas. Its lightweight and corrosion-resistant nature makes it ideal for these applications, contributing to overall aircraft efficiency without compromising passenger safety or comfort.

Future Trends and Technological Advancements

Integration with Smart Composites

Emerging aerospace technologies are exploring the integration of Carbon Fiber Bidirectional Fabric with smart sensors and embedded systems. This combination allows real-time monitoring of structural health, stress distribution, and temperature fluctuations, further enhancing aircraft safety and performance.

Sustainability and Recycling Potential

As the aerospace industry emphasizes sustainability, research is focusing on recycling and reusing Carbon Fiber Bidirectional Fabric. Advances in resin systems and recovery techniques may enable more environmentally friendly manufacturing while preserving the material’s mechanical advantages. These trends position Carbon Fiber Bidirectional Fabric as a forward-looking solution for modern aerospace challenges.

FAQ

What makes Carbon Fiber Bidirectional Fabric suitable for aerospace applications?

Carbon Fiber Bidirectional Fabric combines high strength, low weight, and excellent fatigue resistance, making it ideal for aircraft structures that require durability and lightweight performance.

Can Carbon Fiber Bidirectional Fabric withstand extreme temperatures?

Yes, the fabric exhibits outstanding thermal stability, maintaining structural integrity under high and low temperature conditions commonly encountered at high altitudes.

How does Carbon Fiber Bidirectional Fabric improve fuel efficiency?

Its lightweight nature reduces overall aircraft weight, which lowers fuel consumption, increases payload capacity, and contributes to more efficient flight operations.

Is Carbon Fiber Bidirectional Fabric easy to manufacture into complex components?

Yes, its bidirectional weave allows for flexible fiber orientation, and it integrates well with various resin systems, enabling efficient composite fabrication for complex geometries.

Table of Contents

- Innovation in Aerospace Materials: Combining Lightweight and High Performance

- Material Properties and Performance Advantages

- Manufacturing Flexibility and Design Versatility

- Thermal Performance and Environmental Resistance

- Mechanical Advantages in Aerospace Applications

- Cost Efficiency and Lifecycle Benefits

- Aerospace Design Applications

- Future Trends and Technological Advancements

-

FAQ

- What makes Carbon Fiber Bidirectional Fabric suitable for aerospace applications?

- Can Carbon Fiber Bidirectional Fabric withstand extreme temperatures?

- How does Carbon Fiber Bidirectional Fabric improve fuel efficiency?

- Is Carbon Fiber Bidirectional Fabric easy to manufacture into complex components?