Overview: purpose and performance

Carbon Fiber Bidirectional Fabric is widely used where strength, stiffness and multi-directional load resistance are required. Rather than relying on fibers aligned in just one direction, this fabric weaves carbon filaments into an orthogonal pattern so parts can resist loads from multiple axes. Engineers choose Carbon Fiber Bidirectional Fabric when they need a balanced combination of tensile strength, dimensional stability, and good formability. This article explains what gives Carbon Fiber Bidirectional Fabric its mechanical advantages, compares it to common alternatives, describes manufacturing and design implications, and gives practical guidance for specifying and using it.

What Carbon Fiber Bidirectional Fabric is

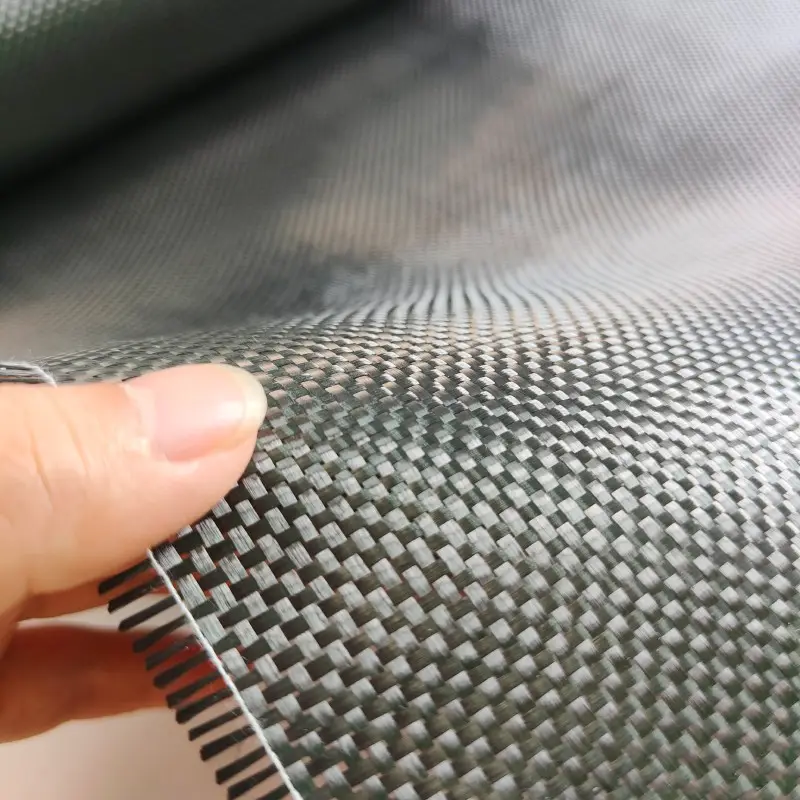

Weave architecture and basic mechanics

Carbon Fiber Bidirectional Fabric typically comes as a woven cloth in which continuous carbon fibers run in both the warp and weft directions. Common weaves include plain, twill and satin patterns; each affects drape, surface finish and local fiber packing. Because fibers are present in two major directions, laminates built from Carbon Fiber Bidirectional Fabric distribute tensile, compressive and shear loads more evenly across a plane than single-direction systems. The result is improved off-axis performance and reduced sensitivity to misaligned loads.

Material constituents and variables that matter

The fabric itself is only one element. The final composite’s performance depends on fiber type (standard, intermediate or high modulus), tow size, sizing chemistry, resin selection (epoxy, vinyl ester, polyester), and fiber volume fraction in the cured laminate. Saying “Carbon Fiber Bidirectional Fabric” implies a textile architecture; designers must pair it with a compatible resin system and processing route to realize the expected mechanical properties.

Mechanical performance: tensile, compression and shear

Tensile behavior and multi-axis strength

In tension, Carbon Fiber Bidirectional Fabric laminates provide reliable strength in both principal in-plane directions. Compared to unidirectional laminates, which peak in one direction only, Carbon Fiber Bidirectional Fabric shows less variation in stiffness and strength when loads rotate or spread. That reliability makes it preferable for panels, fairings and structural skins that face uncertain or combined load paths.

Compression, buckling and shear resistance

Compression strength and buckling resistance are influenced by laminate thickness, resin toughness and consolidation quality. Woven Carbon Fiber Bidirectional Fabric can reduce local buckling tendencies because the weave stabilizes fibers and resists local micro-buckling. Interlaminar shear strength is often improved by the mechanical interlock inherent in the weave, though resin toughness and void content remain controlling factors for out-of-plane performance.

Comparison with unidirectional carbon and other fibers

When unidirectional carbon is superior

If an application carries a dominant, well-defined axial load (for example a tension strap or a unidirectional spar), unidirectional carbon fiber laminates can achieve the highest specific tensile strength per weight along that axis. In contrast, Carbon Fiber Bidirectional Fabric sacrifices some single-axis peak performance to achieve balanced behavior across two axes. The choice hinges on whether loads are predictable and primarily one-directional or more varied.

Fiberglass and aramid alternatives

Fiberglass fabrics are cheaper and tougher in impact scenarios, but they are heavier and much less stiff than Carbon Fiber Bidirectional Fabric for the same thickness. Aramid (Kevlar) gives excellent energy absorption and impact resistance but has lower compressive stiffness and poorer UV resistance compared with carbon. Designers often use hybrid stacks — for example, Carbon Fiber Bidirectional Fabric for stiffness with an outer aramid layer for impact resilience — to balance properties.

Manufacturing and processing effects on strength

Layup method and consolidation quality

The manufacturing route—hand layup, vacuum bag, resin infusion or autoclave cure—has a major effect on final strength. Higher pressure and temperature consolidation (vacuum bag plus heat or autoclave) reduce voids and increase fiber volume fraction, unlocking more of the theoretical strength in Carbon Fiber Bidirectional Fabric. Poor consolidation leaves voids that act as crack initiation sites and degrade fatigue life.

Prepregs and resin control

Prepreg Carbon Fiber Bidirectional Fabric (pre-impregnated with controlled resin content) is commonly used where repeatable mechanical performance is required. Prepregs ensure consistent resin fraction, simpler layup handling and cleaner processing, which helps achieve the target fiber volume and minimize resin-rich regions that lower specific strength.

Design strategies to maximize benefit

Ply stacking and orientation choices

Even with Carbon Fiber Bidirectional Fabric, the stacking sequence matters. Engineers often mix bidirectional plies with unidirectional plies to place maximum strength exactly where needed while keeping multidirectional toughness elsewhere. Finite element analysis combined with laminate theory identifies where Carbon Fiber Bidirectional Fabric yields the best tradeoffs for weight and stiffness.

Hybrid and sandwich constructions

Pairing Carbon Fiber Bidirectional Fabric skins with a lightweight core (foam or honeycomb) produces sandwich panels with very high bending stiffness for minimal mass. In such assemblies, Carbon Fiber Bidirectional Fabric resists in-plane loads while the core resists shear and increases the moment of inertia, which is especially valuable in aerospace and high-performance automotive structures.

Durability and failure modes

Fatigue performance and crack propagation

When properly consolidated and cured, Carbon Fiber Bidirectional Fabric laminates typically show good fatigue life. The woven architecture helps blunt crack tips and distribute cyclic stresses, delaying catastrophic propagation relative to poorly processed or overly brittle laminates. However, fatigue performance is sensitive to void content, resin toughness and environmental exposure.

Impact behavior and delamination risk

Woven Carbon Fiber Bidirectional Fabric tends to tolerate low-energy impacts better than stiff UD layups because fibers interlace and hinder crack growth. Nonetheless, carbon composites are generally less ductile than metals; high-energy impacts may still cause localized crushing, matrix cracking or delamination. Designers mitigate this with tougher matrices, interleaves, core materials or hybrid outer plies.

Testing, standards and real-world verification

Standardized mechanical tests

Acceptable comparisons rely on standardized tests—ASTM tensile, compression and interlaminar shear protocols—applied to representative laminate layups. Because Carbon Fiber Bidirectional Fabric’s properties depend on resin, fiber volume and processing, direct apples-to-apples testing is essential when comparing it to other materials.

Service validation and qualification

For critical applications (aerospace, defense), traceability of material lots, process control and part testing are prerequisites. Carbon Fiber Bidirectional Fabric must be validated not just in lab coupons but in full-scale components under representative loading to certify performance and lifetime.

Practical recommendations and selection guidance

Match fabric to load and shape

Choose Carbon Fiber Bidirectional Fabric when part geometry or loading is multidirectional or when surface finish and dimensional stability matter. If loads are strictly uniaxial and weight optimization is paramount, supplement or replace with unidirectional laminates in key orientations.

Manufacturing capability and cost considerations

If you have access to autoclave or reliable prepreg processes, Carbon Fiber Bidirectional Fabric will deliver predictable, high performance. For budget or low-volume projects, consider vacuum infusion with carefully controlled layup, or combine bidirectional fabric with lower-cost fibers where appropriate.

FAQ

How does Carbon Fiber Bidirectional Fabric compare with unidirectional carbon in strength?

Carbon Fiber Bidirectional Fabric provides strong, balanced tensile and shear properties across two axes, making it superior in applications with multi-directional loads. Unidirectional carbon can surpass bidirectional fabric in peak one-axis tensile strength, but only when loads align with the fiber orientation.

Is Carbon Fiber Bidirectional Fabric suitable for impact-prone applications?

Carbon Fiber Bidirectional Fabric offers improved resistance to minor impacts compared to stiff unidirectional laminates because its woven architecture helps distribute energy. For high-energy impacts, combining Carbon Fiber Bidirectional Fabric with tougher interlayers or hybrid fibers (e.g., aramid) improves overall damage tolerance.

Can I use Carbon Fiber Bidirectional Fabric for curved, complex shapes?

Yes — choose a weave with good drape (twill or satin) and employ careful layup techniques. For tight radii, use multiple smaller plies and consider combining bidirectional plies with unidirectional reinforcements where needed.

What are the best practices to ensure Carbon Fiber Bidirectional Fabric achieves advertised strength?

Use certified material from reputable suppliers, control fiber volume fraction (prefer prepreg if possible), minimize void content through proper consolidation, select an appropriate resin system, and follow validated cure cycles. Quality control and standardized testing post-manufacture are essential.

Table of Contents

- Overview: purpose and performance

- What Carbon Fiber Bidirectional Fabric is

- Mechanical performance: tensile, compression and shear

- Comparison with unidirectional carbon and other fibers

- Manufacturing and processing effects on strength

- Design strategies to maximize benefit

- Durability and failure modes

- Testing, standards and real-world verification

- Practical recommendations and selection guidance

-

FAQ

- How does Carbon Fiber Bidirectional Fabric compare with unidirectional carbon in strength?

- Is Carbon Fiber Bidirectional Fabric suitable for impact-prone applications?

- Can I use Carbon Fiber Bidirectional Fabric for curved, complex shapes?

- What are the best practices to ensure Carbon Fiber Bidirectional Fabric achieves advertised strength?