De Carbonis Fibrae Reticulo Tela Basi Cognoscenda

Quid est pannus textilis carbonii fici?

Textus ex carbonis fibris textilis constat e fibris carbonis textis, quae aliquid mirabile creant - textum qui simul esse potest durus et flexibilis. Hanc rem homines amant quia non multum ponderis habet sed tamen magnam vim ostendit, quod explicat cur in multis artibus et fabricis adhibeatur cum opus est ad solida fundamenta. Quod in primis de hac re notabile est, est eius vis sine pondere addito, quod fabricatores valde curant cum conantur totalem ponderis minutionem adipiscisci. Aliud magnum praetervisum? Potest variis asperis chemicae et temperaturis resistere sine dissolutione. Hac de causa invenitur ubique, ab aeroplanorum partibus ad automobilorum componentes, praesertim ubi ingeniarii opus habent quibusdam quae non ruant etiam cum in asperis conditionibus versentur.

Principales Proprietates et Commoda

Cur carbonis fibrae textilia tantum specialem? Ad specicationes attende: vim mirabilem extensionis habet dum tamen levis est, praeterea flectitur sine rumpendo. Haec combinatio aditum adhibet ad omnia genera applicationum, cogita ab aedificiis levioribus ad solidiorem fabricam bicycli. Non solum ad alliganda sed etiam ad mutandam industriam rationem. Cum aedificatores ad materia leviora convertunt, pecuniam in transporto mercium conservant et totalem energiae consumptionem in processibus fabrefactis minuunt. Et loquamur de durabilitate. Aliter ac ferrum aut alluminium, fibra carbonis non tam cito fatiscit sub onere. Doctrina demonstrat haec materia posse decenniis plus durare quam antiqua genera antequam signa fatiscitationis appareant. Pro manufactoribus quaerentibus pecuniae conservationem per tempus, ad carbonis fibram conversio iam non solum de pondere minuendo agit sed facta est sapientis investitionis ratio trans aeria, automotive, et constructionis ramos.

Factores Necessarii in Carbonis Fibrosi Telae Qualitate

Compositio Materialis et Schema Texturae

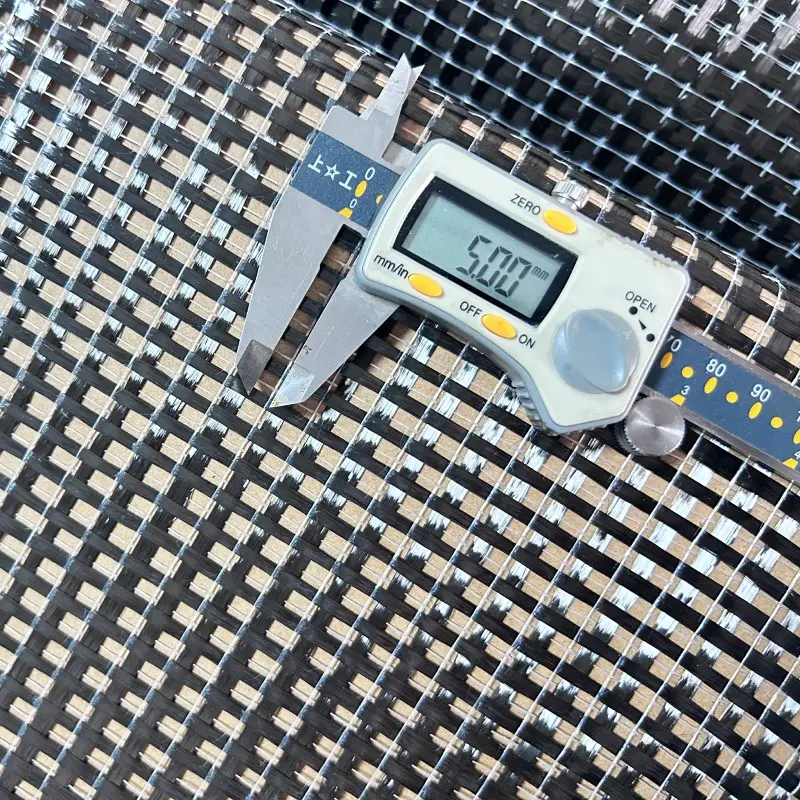

Cur carbon fiber mesh cloth bonum sit qualitatem maxime pendent ex materiae quae in eum ingredientur et ex modo quo illae fibrae intertexantur. Fabricatores varia genera carbonii filorum eligunt propter id quod opus ultimum facturus sit, quod omnia afficit a fortitudine ad flexibilitatem qua tandem evenit. Tria sunt genera texturae quae in mercato hodie conspicua sunt: textura plana, textura twill, et textura satura. Quisque sua habet praestantia. Textura plana stabilitatem praebet praeteritam et visu aequaliter factam videtur cum absoluta. Textura twill efficit superficiem leviorem cum meliore flexione pro quibusdam usibus. Textura satura notabilis est quod superficiem praegranditer leviorem producit tamenque maxime flectibilem remanet. Haec coniunctio optime facta esse necesse est, quia haec elementa mox efficiunt ut textura mechanice in variis usibus bene operetur. Periti nostri iuncturam certarum compositionum fibri cum opportunis texturis ducere in meliores resultatos, id quod in sectoribus ut aeroespacialis aut in apparatis medicinalibus maxime necessarium sit, ubi rem exacte recte factam esse non solum optabile sed omnino necessarium est.

Vis Tensionis vs. Flexibilitas

Ad inspiciendum textum ex fibra carbonis opus est intellegere quomodo vis tensilis coniunctim cum flexibilitate fungeretur. Materiae cum magna vi tensili valde necessariae fiunt in campis ut manufactura aeronautica et productio automobilorum quia aliquid durabile indigent sed levigatum ut vehicula melius performent. Ex altera parte, pRODUCTS aliqua laxitas necessaria est, ut in instrumentis sportivis vel apparatis medicinalibus specialibus, quae melius operantur cum materia flexibilis sine rumpendo. Numeri quoque interessent. Diversae series texti ex fibra carbonis varias vires tensiles habent. Profectus industriales saepe requirunt satis validas ut statim basicae securitatis leges implerentur. Quedam praecipua materiae transiliunt 600 KSI in vi tensili, qua in apertum ferebantur ad conditiones extremas quas nemo turbare vellet. Hanc aequilibrium recte consequi significat textum adiunctum ad applicationem realem aptare, ut nihil rumpatur sub pressione et tamen motum ubi necesse est permittat.

Carbonium Fibrosum vs. Fibra Vitrea

Si intueamur textum ex carbonio contra textum ex vitro, notabiles differentiae emergunt, prae ceteris in fortitudine comparata ad pondus et in generibus operum, in quibus optimum efficiunt. Carbonium excellit quodquam validum est, sed vix ullum pondus habet, idque explicat, cur multae artes ad altum pertinentes id malint. Rerum aerariarum ars carbonium diligit pro partibus aeroplanorum, quia uncia quaeque in caelo ponderatur, et manufactores carrorum id sequuntur, cum materiae leves magis prodesse incipiant. Textum ex vitro aliam tamen historiam narrat. Est crassius et gravius universum, itaque, quamquam opus efficere potest, plerumque electum est, cum ratio pecuniae magis quam summa fortitudo spectatur. Aedificia et naves manufacturae sunt loca consueta, ubi textum ex vitro aeque ac economicum sinitur, etiamsi specifica carbonii non attingit.

Ratio Fortitudinis ad Pondus: Carbonium excellit ratione fortitudinis ad pondus multo altiore, idoneum pro applicationibus quae exigiunt materia levia et durabilia.

Idoneitas Applicationis: Carbonium saepe eligitur pro vehiculis ad altam praestantiam et instrumentis sportivis. Vitrum autem applicatur in industria navali ob oeconomiam.

Tendunt Mercati: Periti saepe praefertionem creacentem in fibris carbonis in regionibus magnae tensionis commemorant, interea quia fibra vitrea ubi limites pecuniae sunt, manet in usu.

Commoda in Applicationibus Magnae Tensionis

Rete fibrae carbonis praecipua commoda in applicationibus magnae tensionis praebet trans artes varias, ut in aeronautica, automobilica, et mercatura sportiva. Proprietates excellentes, sicut vis tensilis summa et flexibilitas, eum permittunt ut sub onere alios materiales superet.

Industria Aeronautica: Rete fibrae carbonis in aedificatione partium aeroplanorum propter levitatem et vim utitur, efficaciam in usu carburis et durabilitatem augens.

Sectorem Automobilicum: Rete saepe in fabrica partium leviu sed fortium utitur, quae ad currus certandi et vehiculos praestantiae sunt necessariae.

Mercatura Sportiva: Materia instrumenta sportiva ut racquetas tennisi et clavos golfici meliorat, praestationem et manubrium emendata offerens.

Incorporatio in Regionibus Magnae Tensionis

Rete carbonii fibrosi saepe ostendit se potius quam pleraeque alternativae in duris conditionibus agere melius secundum varia experimenta in rebus gestis. Exempli gratia, in automobilis, quaestiones indicant vehicula, quae hunc materiam utuntur, minus damnum pati per tempus et multo diutius viae durare quam optiones vulgares. Numeri etiam vera dicunt: haec inventa ad carbonii fibrosi retis problemata praesentia solvere et ianuas aperire ad novas possibilitates in artificiis quae a materialibus suis praestationem summam postulant. Fabricatores hoc iam incipiunt agnoscere: haec res non modo bona est, sed fortasse necessaria erit ad manufacturam progressam consequendam.

Applicationes Texti Carbonii Fibrosi

Casus Utilis Renovationis Structuralis

Textus ex carbonio fibroso mirabiliter adhibetur in multis muneribus consolidationis structurae. Ingeniarii eum adhibent ab antiquis pontonum tabulis roborandis usque ad racquetas tennisi leviores tamen fortiores reddendas. Quod hunc materiem praecipue commendat, est durabilitatem et aetatem structurae auctam praebere. Exempli gratia, aedificia ex lapide caementario – cum textu carbonio fibroso incluso, melius contra aeris inclemencias et alias pressiones resistunt quae alioqui aetatem earum minuerent. Doctrina ostendit aliquas structuras fere semis amplius durare cum consolidatione carbonii fibrosi quam cum methodis communibus. Ferrum fortasse adhuc saepe utitur, sed tandem rubefactatur, dum carbonium fibrosum per annos manet validum. Praeterea, manufactores fibri fortitudinis proprietates variare possunt pro varietate oneris vel pressionis quas productum ultimum sustinere debet, qua de causa multi propositi de rebus infrastructurae iamdudum solutiones carbonii fibrosi postulant.

Applicationes Industriales Speciales

Textus ex carbono fibroso praecipue in variis applicationibus industrialibus in sectoribus variis, ut fabricatio automobilorum, aeronautica, et maritima, versatur. In vehiculis huiusmodi textus adhibetur, ut partes fiant leves et fortes, qua ex re consumptio carburantis minuitur et melioratur actio vehiculorum. Ad aeronavium et navium spatii usus, textus carbono fibrosus ingeniarios adiuvat ut structuras construant quae vim retineant sine pondere superfluo, id quod ad progressum technologiae volandi necessarium est. Etiam applicationes maritimae iuvantur, quia textus in condicionibus asperis maris diutius manet et in aquis salsis melius agit. Exempla realia sunt, ut iacula maria velocissima quae certamina superant ob carinae textu carbono fibroso roboratae diuturnitatem. Periti saepe commemorant, non solum vim excedere, sed etiam pecuniam conservare in longo aere per productionem celeriorem et novas formaturas productorum in pluribus campis aperire.

Quomodo Eligere Ius Textum Carbonis Pro Tuo Negotio

Evaluando Conditiones Ambientales

Legere iusum textum fibrae carbonis incipit a scientia qua variae conditiones ambientales influant in proprietates operativas. Variabiles ambientales ut fluctuationes tempestatum, gradus humiditatis, et expositiones chemicas omnes partes magnas agunt in determinando quinam typus texti optime valeat. Exempli gratia, in locis ubi alta humiditas contingit, ubi necessariae sunt optiones resistentes umori, ut vitentur damna diuturna ab absorptione aquae. Conditones chemicae aliud problema offerunt, quod tegumenta specialia in quibusdam textibus requirent, ut substantias corrosivas sustineant nihilominus integritatem structuralem compromittentes. Antequam de electione texti deliberetur, profectus est ut prius condicionibus loci specificis accurate inspiciantur. Circumstantiae loci aeque valent ac res ipsa quam textus praestabit in praxi. Illi qui hunc adagium sequuntur, plerumque materiales adipiscuntur quae ad suas particulas necessitates aptantur, potius quam aliquid generale suscipiant.

Quomodo Adaptare Specifica Texti Ad Onus Requisita

Antequam eligas carbonis texturam pro iis rebus, multum iuvat scire quantitatem ponderis quod structura ferre debet. Quanta massa materiae sit, numeri de fortitudine texturae, et quam crassus texturae fila sint, omnia convenire debent cum eo quod in opere concreto exigitur. Si hoc praetermittas, fortasse postea res male gesta erit, cum pressura addatur. Exempli gratia, pontes et aedificia publica texturam requirent, quae vim gravem sustinere possit, quia pondera ingentia ferunt. Alia tamen est ratio apud instrumenta sportiva: ibi melius sunt materiae leviorem, quia athletae opus habent rebus quae flectuntur nec rumpuntur et onus non addunt. Tabulae specificarum vel schemata a manufactore edita adiuvare possunt, ut scias quae textura ad certum usum idonea sit. Haec ratione exacte tractata inter successum et defectum interponunt, ut ingeniosi artifices virtutes mirabiles carbonis texturae adhibeant et tamen rem utilem et tutam reddant.

Conservatio et Diuturnitas Carbonis Fibrae Texturae

Optimae Purificationis et Custodiae Rationes

Ut carbonis fibrae retis bene fungantur, cura et custodia propria multum interest. Cum munda sunt, adhibe saponem mitis vel producta ad hoc confecta pro materia carbonis fibrae, quia chemicals asperae retis noceunt. Pilae mollis sunt optima pro lavando, nam materia aspera superficiem laedit. Post munda, arida esse debet penitus quia humores residui problemata creant. Retis in loco frigido et arido servandum est, ne in sole directo vel apud res quae aerem polluunt. Humiditas et caliditas hostes sunt, quae materiam celerius dissolvunt. Plurimi fabricatores mandata de cura subnectunt cum venditione productorum suorum, itaque tempus legendi haec proficit. Haec basica sequendo, tam diuturnitas quam efficacia carbonis fibrae retis componentium servatur.

Signa Usus et Tempus Replacementis

Fibrae carbonis texturae inspicere saepe iuvat praecoces signa usu sentire priusquam problemata graviora fiant. Attende ad res sicut marginis rapti, locorum ubi materia durior quam oportet sentitur, aut rimas et distorsiones quae visu notabiles sunt. Cum haec mala apparent, saepe significat texturam non amplius optime functionem et igitur examinanda pro possibili mutione. Quam saepe inspiciendum sit, pendet ex usu texturae et ex condicione qua cotidie continetur. Plures technici censent inspectionibus instituendis ut wear non subrepat insciis. Ante manutenentia providere iuvat proiectis inopinatis dilationibus sublatis et texturae carbonis fibrae ut constanter operari per tempus.

Industria trends et Innovations

Progressus in Fabricatione Sustentabili

Magnas quidem mutationes videmus in fabrica fibrae carbonis hodie. Coepere aliae societates uti rationibus melioribus, verbi gratia, solis utendi et vias reperiendi ut sordes minuantur in productione. Curiosum est quod haec conversio tandem meliorem qualitatem producti finiti praebet pro fibra carbonis texta dum in rem texit. Aspice quae nunc in officinis fiunt - usus energiae 30% fere minuendus est comparatus cum rationibus antiquis, et sordes multo minores in solo deponuntur. Commodity duplex est: diuturno tempore negotia pecuniam conservant dum tamen partem suam pro planeta agunt. Plurimi fabricatores intellegunt se viridem iter sequi non solum bonis moribus inservire, sed etiam rationem negotii praebere cum de productione fibrae carbonis textae sermo fit.

Nanocomposita Augmenta in Textiliologia Reticulata

Industria textilis carbonii fibrosi testatur magnas mutationes per nanocomposita, quae emendationes in proprietatibus materiae efficiunt sine onere addito. Laboratoria investigationis per orbem terrarum nitebantur ut haec minuta composita in processus fabricandi iam existentes integrarent, efficiens quoddam medium inter antiqua et futura. Hoc notabile redditur quod modo fabricae possunt carbonii fibrosi producta fortiora sed leviora producere simpliciter per componentes nano-dimensionales in productione additos. Plurimi incolarum sectoris credunt progressum huius in partes futuras directionem carbonii fibrosi technologiae determinaturum esse. iam primum videre applicationes in variis campis, praecipue in partibus aeronauticis et vehiculorum potens ubi omnis grammo salvatus magni ponderis est.

FAQ

Quid est textilis carbonis fibrosae vestis usus?

Textilis carbonis fibrosae vestis ad varia usus, inter quae aeris navigium, automotiva, et sportus rebus commodis, ubi levitas et fortitudo idonea sunt.

Quomodo textilis carbonis fibrosae vestis prodesse aedificandi negotiis?

Textus ex carbonio fibroso structuris durabilitatem et firmitatem meliorat minuendoque pondere ad efficienciam meliorem energiae.

Quae sunt praevantiones usus textus carbonii fibrosi prae vitro fibroso?

Textus carbonii fibrosi excellit propter rationem fortitudinis ad pondus altiorem, idoneum reddens pro industriae ubi prestantia et pondus sunt crucialia.

Quomodo textura retis carbonii fibrosi proprietates afficit?

Textura, ut plana, twill, aut serica, fortitudinem, flexibilitatem, et stabilitatem textus carbonii fibrosi afficit, idoneitatem pro applicationibus certis influens.

Quae praecepta curandi textum carbonii fibrosi sunt optanda?

Curatio optima pulsatilis munditias cum detergents lenibus, idoneas conditiones servandi, et inspectiones cotidianas ad textum diuturnitatem et prestantiam servandam includit.

Index Rerum

- De Carbonis Fibrae Reticulo Tela Basi Cognoscenda

- Factores Necessarii in Carbonis Fibrosi Telae Qualitate

- Carbonium Fibrosum vs. Fibra Vitrea

- Applicationes Texti Carbonii Fibrosi

- Quomodo Eligere Ius Textum Carbonis Pro Tuo Negotio

- Conservatio et Diuturnitas Carbonis Fibrae Texturae

- Industria trends et Innovations

-

FAQ

- Quid est textilis carbonis fibrosae vestis usus?

- Quomodo textilis carbonis fibrosae vestis prodesse aedificandi negotiis?

- Quae sunt praevantiones usus textus carbonii fibrosi prae vitro fibroso?

- Quomodo textura retis carbonii fibrosi proprietates afficit?

- Quae praecepta curandi textum carbonii fibrosi sunt optanda?