The answer lies in the fact that they not only possess mechanical properties comparable to those of traditional thermoset materials but also offer core advantages such as recyclability and ease of processing, perfectly aligning with the urgent global demand for sustainable development. At Dr. Reinforcement, with 13 years of deep expertise in the carbon fiber field, we fully understand the importance of material innovation—it is precisely through our keen insight into industry trends that we have taken the lead in the R&D and production of thermoplastic carbon fiber plates, committed to providing customers with more efficient, environmentally friendly, and economical solutions. Today, let’s explore this future-leading material technology together and see how it can inject new momentum into your projects!

Unique Advantages of Thermoplastic Carbon Fiber Composites

1、Revolutionary Processing Advantages: High Speed, Low Cost

Short Cycle, High Efficiency: The processing of thermoplastic composites is a physical melting-cooling process, reducing molding time to just a few minutes or even dozens of seconds, significantly boosting production efficiency. At Dr. Reinforcement, we utilize advanced processes to achieve rapid mass production, helping you substantially lower unit costs and respond faster to market demands.

Reprocessability and Repairability: Thermoset materials are often difficult to repair once damaged, while thermoplastic materials support localized heating for repair, greatly enhancing product maintainability and service life. Defective products and scraps generated during production can also be recycled and reused, further reducing waste—this aligns perfectly with Dr. Reinforcement’s ongoing commitment to "green manufacturing."

2、Outstanding Performance

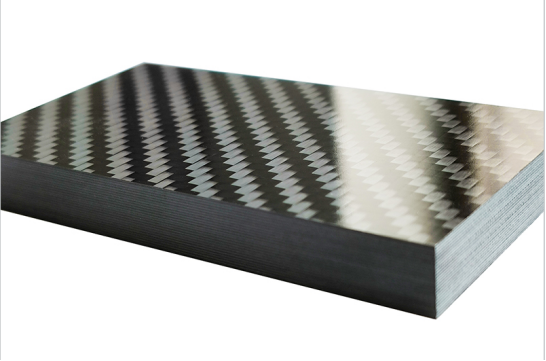

High Toughness and Impact Resistance: Thermoplastic carbon fiber composites exhibit superior toughness and impact resistance, making them suitable for high-safety scenarios. The thermoplastic carbon fiber plates provided by Dr. Reinforcement maintain high strength while significantly improving resistance to brittle fracture.

Chemical Corrosion and Fatigue Resistance: Using high-performance resins such as PEEK and PPS, our materials maintain long service life even in harsh environments like automotive engine bays and chemical settings.

Unlimited Shelf Life: Thermoplastic prepregs require no refrigeration and have no storage time limitations, simplifying supply chain management—Dr. Reinforcement ensures stable supply throughout, helping you seamlessly align production plans.

3、Green and Sustainable: An Inevitable Choice for the Future

Recyclability: Against the backdrop of global carbon neutrality efforts, thermoplastic composites enable the separation and recycling of carbon fibers and resins, complying with circular economy principles. Choosing Dr. Reinforcement means not only selecting a material but also embracing a commitment to environmental responsibility.

Broad Application Areas, Empowering Industry Innovation

Leveraging these advantages, thermoplastic carbon fiber composites are widely used in aerospace, automotive manufacturing, sports equipment, and many other fields:

In aerospace, they are applied to components like fuselages and wings, reducing weight, improving fuel efficiency, and enhancing fatigue resistance.

In the automotive industry, many of Dr. Reinforcement’s customers use them for body frames, seat skeletons, and more, achieving lightweighting and safety unification.

In sports products such as golf clubs and bicycle frames, their high stiffness and lightweight properties significantly enhance performance and user experience.

Additionally, they show broad prospects in medical devices, rail transportation, and other sectors.

Facing Challenges? Dr. Reinforcement Offers Mature Solutions

Although thermoplastic carbon fiber offers significant advantages, its widespread application still faces challenges such as the high cost of high-performance resins, the need for high-temperature and high-pressure processing environments, and stricter interface bonding requirements. However, these are precisely the areas where Dr. Reinforcement continues to make breakthroughs—leveraging 13 years of technical expertise and the production capacity of our 8,000㎡ factory, we have developed multiple cost-effective thermoplastic carbon fiber plates and provide comprehensive process guidance and service support to help customers effectively address technical challenges related to temperature, pressure, and fiber bonding.

Choose Dr. Reinforcement, Choose a Reliable Future

We are certified with ISO 9001 Quality Management System and CE EU certifications, ensuring strict quality control and reliable performance for every batch of carbon fiber fabrics and thermoplastic carbon fiber plates. Over the past 13 years, serving over a million customers, we have developed a deep understanding of market needs and customer expectations. If you are looking for a stronger, lighter, more environmentally friendly, and recyclable new material, contact us! Dr. Reinforcement is not just your supplier but also your partner on the path to innovation.

Let’s join hands to set the next industry benchmark with thermoplastic carbon fiber materials!

Click to inquire for customized solutions and competitive quotes.

Whatsapp:+86 19121157199

Email:[email protected]

Hot News

Hot News