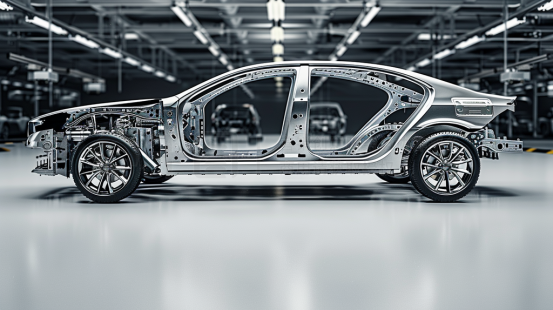

In today’s automotive manufacturing industry, where efficiency and high quality are continuously pursued, development cycles for new vehicle models are increasingly compressed, and demands for part precision and reliability are constantly rising. As a core inspection tool in the development process, the automotive functional master model’s performance directly impacts vehicle assembly quality and development efficiency. Established 13 years ago, Dr.reinforcement has always been dedicated to the R&D and manufacturing of carbon fiber materials, providing high-strength carbon fiber cloth products to over a million customers worldwide, including 200,000 loyal repeat clients—a testament to our expertise and credibility in the field of materials.

Traditionally, dummy blocks in functional master models were commonly made of aluminum alloy. Although aluminum alloy offers a certain level of strength, its high density often necessitates increased wall thickness to meet structural requirements. This results in a significant increase in overall weight compared to actual parts, leading to deviations when installed in actual vehicles and limiting its application scope.

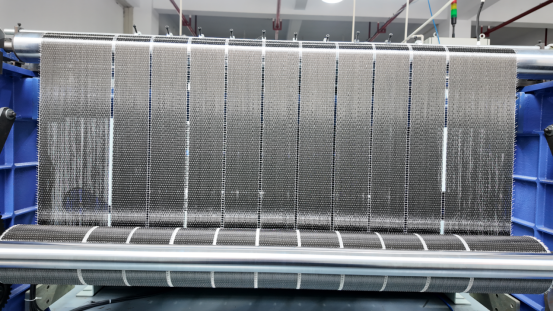

Leveraging 13 years of technical expertise, Dr.reinforcement employs German Dornier weaving equipment to ensure uniform tension and a drum-free finish in carbon fiber cloth. Combined with an experienced weaving team, we produce carbon fiber modules that are both lightweight and high-strength. This material not only perfectly meets the usage requirements of automotive functional master models but can also be directly installed on actual vehicles for real-car matching analysis, completely overcoming the limitations of traditional materials.

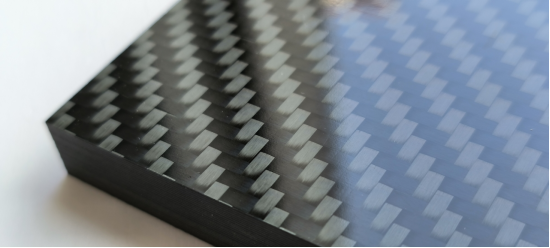

Carbon fiber materials offer significant advantages such as light weight, high strength, corrosion resistance, and high-temperature resistance. Dr.reinforcement’s carbon fiber cloth products are ISO-9001 and CE certified, ensuring stable and reliable quality. When applied to automotive master models, they not only substantially reduce the weight of dummy blocks but also enhance overall rigidity, wear resistance, impact resistance, and fatigue resistance. Additionally, carbon fiber’s excellent electromagnetic shielding properties effectively protect in-vehicle electronic devices from interference.

By incorporating Dr.reinforcement’s carbon fiber materials into automotive functional master models, automakers can significantly improve model precision and stability, thereby optimizing overall vehicle quality and performance. This material transformation also helps reduce comprehensive production costs, enhance development efficiency, and deliver substantial economic benefits and competitive advantages to the automotive manufacturing industry.

Looking ahead, as carbon fiber application technology continues to mature, Dr.reinforcement will further leverage its 8,000-square-meter in-house production base and advanced manufacturing processes to deepen innovative applications of materials in the automotive sector. We look forward to collaborating with more industry partners to jointly advance the development of automotive functional master model technology, empowering the automotive manufacturing industry to move toward a new stage of higher quality and efficiency.

Email:[email protected]

Whatsapp:+86 19121157199

Hot News

Hot News