The construction industry stands at the threshold of a revolutionary transformation, driven by advanced materials that promise to redefine structural engineering standards. Among these groundbreaking innovations, reinforced carbon fiber cloth emerges as a game-changing solution that addresses the growing demands for stronger, lighter, and more durable building materials. This advanced composite material combines the exceptional strength-to-weight ratio of carbon fibers with the flexibility and ease of application that modern construction projects require. As infrastructure ages and new construction challenges arise, reinforced carbon fiber cloth offers unprecedented opportunities to enhance structural integrity while reducing overall project costs and construction timelines.

Understanding the Fundamentals of Advanced Carbon Fiber Technology

Material Composition and Manufacturing Excellence

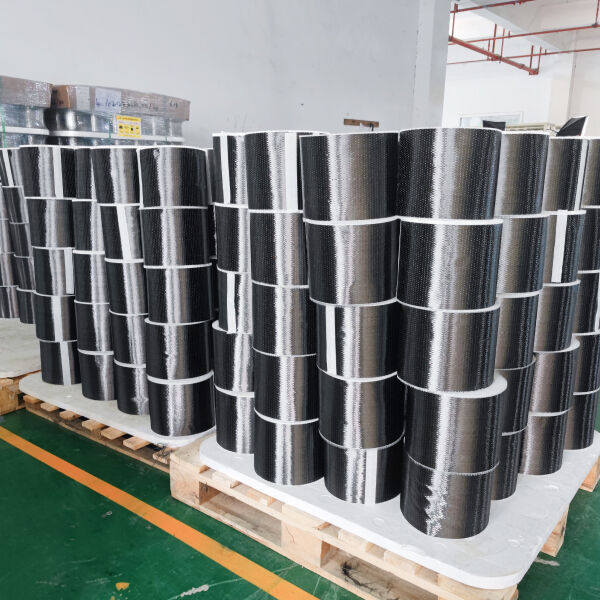

Reinforced carbon fiber cloth represents the pinnacle of composite material engineering, consisting of thousands of carbon filaments woven together to create an exceptionally strong and lightweight fabric. The manufacturing process involves carbonizing organic precursor materials at extremely high temperatures, typically exceeding 1000 degrees Celsius, which transforms the base materials into pure carbon fibers. These individual fibers possess tensile strength that can exceed steel by up to five times while weighing approximately 75% less. The weaving pattern and fiber orientation significantly impact the final performance characteristics of reinforced carbon fiber cloth, with bidirectional weaves providing optimal strength distribution for construction applications.

The integration of specialized resin systems during the manufacturing process creates the reinforcement matrix that gives reinforced carbon fiber cloth its unique properties. Advanced epoxy formulations ensure proper fiber-to-matrix adhesion while maintaining flexibility during installation. Quality control measures throughout production guarantee consistent fiber alignment and uniform thickness, critical factors that directly influence the material's performance in real-world construction environments. Modern manufacturing facilities employ automated weaving techniques and precision cutting systems to deliver reinforced carbon fiber cloth products that meet stringent industry specifications and quality standards.

Mechanical Properties and Performance Characteristics

The mechanical properties of reinforced carbon fiber cloth surpass traditional construction materials in multiple critical areas, making it an ideal choice for structural strengthening applications. Tensile strength values typically range from 3000 to 4000 MPa, significantly exceeding conventional steel reinforcement while maintaining excellent fatigue resistance over extended service periods. The elastic modulus of reinforced carbon fiber cloth approaches 230 GPa, providing exceptional stiffness that translates to reduced deflection in structural elements. These superior mechanical characteristics enable engineers to achieve remarkable load-bearing capacity improvements with minimal additional weight or thickness.

Environmental resistance represents another crucial advantage of reinforced carbon fiber cloth, particularly in harsh construction environments where traditional materials may deteriorate rapidly. The inherent corrosion resistance eliminates concerns about rust or chemical degradation, ensuring long-term structural integrity without requiring extensive maintenance programs. Temperature stability allows reinforced carbon fiber cloth to maintain its properties across wide temperature ranges, from extreme cold to elevated temperatures commonly encountered in industrial applications. Chemical inertness prevents reaction with concrete alkalinity, chlorides, and other aggressive substances that typically compromise conventional reinforcement materials over time.

Revolutionary Applications in Modern Construction Projects

Structural Strengthening and Rehabilitation Solutions

The application of reinforced carbon fiber cloth in structural strengthening projects has transformed how engineers approach building rehabilitation and upgrade requirements. Existing concrete structures can achieve significant load-bearing capacity increases through strategic placement of reinforced carbon fiber cloth systems, often eliminating the need for costly demolition and reconstruction activities. Bridge strengthening projects particularly benefit from this technology, as the lightweight nature of carbon fiber cloth minimizes additional dead load while providing substantial flexural and shear capacity enhancements. The external bonding method allows for rapid installation with minimal disruption to ongoing operations, making it ideal for critical infrastructure projects where downtime must be minimized.

Seismic retrofitting applications showcase the exceptional performance of reinforced carbon fiber cloth in enhancing structural resilience against earthquake forces. The material's high strength and flexibility provide excellent confinement effects for concrete columns and walls, improving ductility and preventing brittle failure modes during seismic events. Wrapping techniques using reinforced carbon fiber cloth can increase the axial load capacity of concrete columns by up to 100% while significantly improving their ability to withstand lateral forces. These applications have proven particularly valuable in regions with high seismic activity, where upgrading existing structures to current earthquake resistance standards requires innovative strengthening solutions.

New Construction Integration and Design Innovation

Forward-thinking construction projects increasingly incorporate reinforced carbon fiber cloth during initial design phases to optimize structural performance from the ground up. Hybrid reinforcement systems combining traditional steel reinforcement with strategically placed carbon fiber cloth elements achieve superior performance characteristics while reducing overall material consumption. This integrated approach allows designers to create lighter structural elements without compromising strength or durability requirements. The reduced weight translates to smaller foundation requirements and lower seismic forces, creating cascading benefits throughout the entire structural system design.

Architectural applications of reinforced carbon fiber cloth enable innovative design solutions that were previously impossible with conventional materials. Complex curved surfaces and intricate geometric forms become achievable through the flexibility and conformability of carbon fiber cloth systems. The material's transparency to electromagnetic waves makes it ideal for applications where radio frequency transmission must be maintained, such as communication towers and specialized industrial facilities. These unique properties expand the creative possibilities for architects while ensuring structural performance meets or exceeds traditional design standards.

Economic Impact and Cost-Benefit Analysis

Initial Investment Considerations and Long-Term Value

While the initial material cost of reinforced carbon fiber cloth typically exceeds traditional reinforcement options, comprehensive lifecycle cost analysis reveals significant economic advantages that justify the investment. The rapid installation process reduces labor requirements and project duration, translating to substantial savings in construction overhead and indirect costs. Projects utilizing reinforced carbon fiber cloth often complete strengthening work in days rather than weeks, minimizing business disruption and associated revenue losses for commercial facilities. The elimination of heavy lifting equipment and complex formwork further reduces installation costs while improving job site safety conditions.

Maintenance cost reductions represent a major economic benefit of reinforced carbon fiber cloth systems throughout the service life of treated structures. The corrosion resistance eliminates periodic replacement cycles associated with steel reinforcement, while the durability characteristics minimize inspection and repair requirements. Insurance benefits may also apply to structures strengthened with reinforced carbon fiber cloth, as improved structural performance can reduce risk profiles and associated premium costs. These long-term economic advantages often result in payback periods of less than five years for many applications, making reinforced carbon fiber cloth a financially attractive option for building owners and infrastructure managers.

Market Trends and Industry Adoption Patterns

The global market for reinforced carbon fiber cloth in construction applications continues expanding rapidly, driven by increasing awareness of its performance benefits and growing acceptance among engineers and contractors. Industry surveys indicate adoption rates have increased by over 200% in the past decade, with particular growth in infrastructure rehabilitation projects where traditional methods prove inadequate or economically unfeasible. Government initiatives promoting sustainable construction practices and infrastructure resilience contribute to market expansion, as reinforced carbon fiber cloth aligns with environmental goals while delivering superior performance characteristics.

Regional market variations reflect different infrastructure needs and regulatory environments, with developed countries leading adoption for rehabilitation projects while emerging markets show strong growth in new construction applications. Professional education and certification programs have accelerated industry acceptance by ensuring proper installation techniques and quality control measures. The establishment of standardized testing protocols and design guidelines provides engineers with confidence in specifying reinforced carbon fiber cloth systems for critical structural applications. Market forecasts predict continued strong growth as infrastructure aging accelerates globally and performance demands increase across all construction sectors.

Installation Methodologies and Technical Excellence

Surface Preparation and Application Techniques

Successful implementation of reinforced carbon fiber cloth systems requires meticulous attention to surface preparation and installation procedures that ensure optimal bond strength and long-term performance. Concrete surface preparation typically involves mechanical grinding or sandblasting to remove contaminants and create the proper surface profile for maximum adhesion. Crack injection and surface repair work must be completed prior to reinforced carbon fiber cloth installation to ensure uniform load transfer and prevent stress concentrations. Environmental conditions during installation significantly impact cure rates and final bond strength, requiring careful monitoring of temperature, humidity, and wind conditions throughout the application process.

The wet layup application method represents the most common installation technique for reinforced carbon fiber cloth, involving the impregnation of dry fabric with resin systems during installation. Proper resin-to-fiber ratios ensure complete saturation while avoiding excess resin that can compromise mechanical properties. Rolling techniques eliminate air bubbles and ensure uniform thickness across the entire application area. Quality control measures include regular testing of mixed resins and monitoring of cure progression to verify proper chemical reactions. Advanced installation crews utilize specialized tools and monitoring equipment to maintain consistent application quality and achieve specified performance requirements.

Quality Assurance and Performance Verification

Comprehensive quality assurance programs ensure that reinforced carbon fiber cloth installations meet design specifications and performance requirements through systematic testing and inspection protocols. Pull-off adhesion testing verifies bond strength at predetermined intervals across the installation area, providing quantitative data on system integrity. Visual inspection procedures identify potential defects such as air bubbles, dry spots, or fiber misalignment that could compromise performance. Documentation requirements include photographic records, test results, and installation parameters that provide complete traceability for future reference and warranty purposes.

Long-term monitoring programs track the performance of reinforced carbon fiber cloth systems over extended service periods, providing valuable data for future design optimization and maintenance planning. Strain gauge installations can provide real-time monitoring of structural response and load distribution, enabling predictive maintenance strategies. Regular inspection schedules identify any changes in system condition and allow for timely intervention if necessary. These comprehensive monitoring approaches ensure that reinforced carbon fiber cloth systems continue delivering expected performance throughout their design service life while providing data for continuous improvement of installation and design methodologies.

Future Technological Developments and Industry Evolution

Advanced Material Innovations and Next-Generation Products

Research and development efforts continue advancing reinforced carbon fiber cloth technology through innovative fiber treatments and resin formulations that enhance performance characteristics beyond current capabilities. Nanotechnology integration promises to create hybrid materials with self-healing properties and enhanced environmental resistance. Smart fiber systems incorporating sensors and monitoring capabilities will enable real-time structural health monitoring directly within reinforced carbon fiber cloth installations. These technological advances will further expand application possibilities while reducing lifecycle costs through improved durability and predictive maintenance capabilities.

Manufacturing innovations focus on reducing production costs while maintaining or improving quality standards, making reinforced carbon fiber cloth more accessible for mainstream construction applications. Automated manufacturing processes and improved precursor materials contribute to cost reductions that enhance market competitiveness. Recycling technologies for carbon fiber materials address sustainability concerns while creating circular economy opportunities within the construction industry. These developments position reinforced carbon fiber cloth as an increasingly attractive option for a broader range of construction projects and budget constraints.

Integration with Emerging Construction Technologies

The convergence of reinforced carbon fiber cloth technology with digital construction methodologies creates unprecedented opportunities for precision application and performance optimization. Building Information Modeling systems now incorporate carbon fiber strengthening designs, enabling accurate quantity calculations and installation planning. Robotic application systems under development promise to improve installation consistency while reducing labor requirements for large-scale projects. Augmented reality systems assist installers in achieving precise placement and alignment of reinforced carbon fiber cloth systems according to design specifications.

Artificial intelligence applications analyze structural performance data from reinforced carbon fiber cloth installations to optimize future designs and predict maintenance requirements. Machine learning algorithms process vast databases of installation and performance information to identify patterns and improve design methodologies. These technological integrations will accelerate adoption rates while ensuring optimal performance and cost-effectiveness for reinforced carbon fiber cloth applications across diverse construction projects. The synergy between advanced materials and digital technologies positions the construction industry for transformational improvements in efficiency, sustainability, and performance.

FAQ

How long does reinforced carbon fiber cloth last in construction applications

Reinforced carbon fiber cloth systems typically provide service lives exceeding 50 years when properly installed and maintained. The inherent corrosion resistance and chemical stability of carbon fibers ensure long-term performance without degradation from environmental exposure. Regular inspection and maintenance of the resin matrix can extend service life even further, with many installations showing no significant performance decline after decades of service in harsh construction environments.

What are the main advantages of reinforced carbon fiber cloth over steel reinforcement

The primary advantages include exceptional strength-to-weight ratio, complete corrosion resistance, rapid installation capabilities, and minimal structural modification requirements. Reinforced carbon fiber cloth weighs approximately 75% less than equivalent steel reinforcement while providing superior tensile strength and fatigue resistance. The elimination of corrosion concerns significantly reduces long-term maintenance costs and extends structural service life compared to traditional steel reinforcement systems.

Can reinforced carbon fiber cloth be used in all climate conditions

Reinforced carbon fiber cloth performs excellently across a wide range of climate conditions, from arctic cold to tropical heat and humidity. The material maintains its mechanical properties at temperatures ranging from -40°C to +150°C, making it suitable for virtually all construction environments. UV resistance treatments protect against solar degradation in outdoor applications, while moisture resistance ensures performance in high-humidity conditions without compromising structural integrity.

What training is required for contractors installing reinforced carbon fiber cloth

Professional installation of reinforced carbon fiber cloth requires specialized training covering material handling, surface preparation, mixing procedures, and application techniques. Most manufacturers offer certification programs that provide hands-on training and testing to ensure installers understand proper procedures and quality control requirements. Continuing education programs keep certified installers updated on new products, techniques, and industry standards to maintain installation quality and performance standards.

Table of Contents

- Understanding the Fundamentals of Advanced Carbon Fiber Technology

- Revolutionary Applications in Modern Construction Projects

- Economic Impact and Cost-Benefit Analysis

- Installation Methodologies and Technical Excellence

- Future Technological Developments and Industry Evolution

-

FAQ

- How long does reinforced carbon fiber cloth last in construction applications

- What are the main advantages of reinforced carbon fiber cloth over steel reinforcement

- Can reinforced carbon fiber cloth be used in all climate conditions

- What training is required for contractors installing reinforced carbon fiber cloth