The aerospace industry continues to push the boundaries of material science, seeking solutions that deliver exceptional strength while maintaining minimal weight. Among the most transformative materials driving this evolution is reinforced carbon fiber cloth, a composite material that has become indispensable in modern aircraft manufacturing. This advanced textile combines carbon fiber filaments with specialized weaving patterns to create a material that offers unprecedented strength-to-weight ratios, making it ideal for critical aerospace applications where performance and reliability are paramount.

The revolutionary impact of reinforced carbon fiber cloth extends far beyond its impressive mechanical properties. This material has fundamentally altered how engineers approach aircraft design, enabling the creation of lighter, more fuel-efficient aircraft while maintaining the structural integrity required for safe operation. The adoption of reinforced carbon fiber cloth has led to significant improvements in fuel economy, reduced emissions, and enhanced performance characteristics that were previously impossible with traditional materials like aluminum and steel.

Understanding the Composition and Structure of Reinforced Carbon Fiber Cloth

Carbon Fiber Fundamentals

Reinforced carbon fiber cloth begins with individual carbon fibers, each measuring just a few micrometers in diameter. These fibers are produced through a complex process that involves heating precursor materials, typically polyacrylonitrile or pitch, to extremely high temperatures in controlled environments. The resulting carbon fibers exhibit exceptional tensile strength and modulus, with strength levels often exceeding 3,000 MPa while maintaining remarkable lightness.

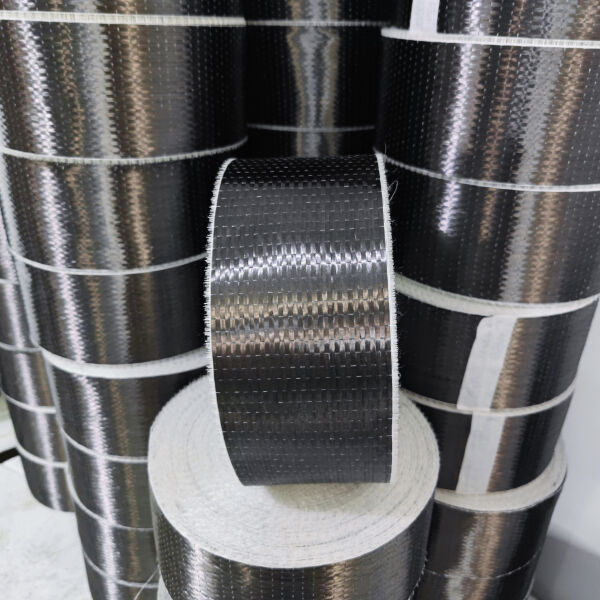

The manufacturing process of reinforced carbon fiber cloth involves weaving these individual carbon fibers into various patterns, including plain weave, twill weave, and satin weave configurations. Each weaving pattern imparts different characteristics to the final cloth, affecting properties such as drapability, surface finish, and mechanical performance. The choice of weaving pattern depends on the specific application requirements and the manufacturing processes that will be used to create the final composite part.

Reinforcement Mechanisms

The reinforcement in reinforced carbon fiber cloth comes from the strategic arrangement of carbon fibers in multiple directions within the fabric structure. This multidirectional orientation allows the material to resist loads from various angles, providing superior mechanical performance compared to unidirectional fiber arrangements. The cloth format also facilitates easier handling during manufacturing processes, making it more practical for complex geometric shapes common in aerospace applications.

Advanced reinforced carbon fiber cloth often incorporates hybrid constructions that combine carbon fibers with other high-performance fibers such as aramid or glass fibers. These hybrid configurations can provide enhanced impact resistance, improved damage tolerance, or reduced manufacturing costs while maintaining the primary benefits of carbon fiber reinforcement. The integration of different fiber types requires careful consideration of compatibility and processing requirements to ensure optimal performance.

Manufacturing Processes and Quality Control

Production Techniques

The production of high-quality reinforced carbon fiber cloth requires sophisticated manufacturing equipment and precise process control. Modern weaving machines capable of handling carbon fiber filaments operate under controlled tension and environmental conditions to prevent fiber damage and ensure consistent fabric properties. The weaving process parameters, including warp and weft fiber tensions, beat-up force, and loom speed, significantly influence the final cloth characteristics.

Quality control during reinforced carbon fiber cloth manufacturing involves continuous monitoring of fiber alignment, fabric weight, and weave pattern consistency. Advanced inspection systems using optical scanning and image analysis detect defects such as broken filaments, incorrect weave patterns, or variations in fabric density. These quality measures ensure that the reinforced carbon fiber cloth meets the stringent specifications required for aerospace applications where material reliability is critical.

Surface Treatment and Sizing

Surface treatment of reinforced carbon fiber cloth plays a crucial role in optimizing the interface between the carbon fibers and the matrix resin used in composite manufacturing. The sizing applied to carbon fibers during cloth production must be compatible with the intended resin system to achieve maximum adhesion and load transfer efficiency. Different sizing formulations are available for various resin types, including epoxy, bismaleimide, and thermoplastic systems commonly used in aerospace applications.

The application of sizing to reinforced carbon fiber cloth also serves to protect the carbon fibers during handling and processing operations. Without proper sizing, carbon fibers can be susceptible to mechanical damage that reduces their strength and creates stress concentrations in the final composite part. The sizing formulation must balance handleability requirements with the need for complete removal or dissolution during the composite curing process to avoid compromising the fiber-matrix interface.

Aerospace Applications and Performance Benefits

Aircraft Structure Applications

Reinforced carbon fiber cloth has found extensive application in primary aircraft structures, including wing skins, fuselage panels, and control surfaces. The material's exceptional stiffness-to-weight ratio enables the design of thinner, lighter structural components that maintain the load-carrying capacity required for safe operation. This weight reduction translates directly into improved fuel efficiency and increased payload capacity, making reinforced carbon fiber cloth invaluable for commercial and military aircraft manufacturers.

The use of reinforced carbon fiber cloth in aircraft structures also provides opportunities for innovative design approaches that were not feasible with traditional metallic materials. The ability to tailor fiber orientations within the cloth structure allows engineers to optimize load paths and reduce stress concentrations, leading to more efficient structural designs. Additionally, the excellent fatigue resistance of carbon fiber composites made from reinforced carbon fiber cloth results in longer service intervals and reduced maintenance requirements.

Engine Component Integration

Modern aircraft engines increasingly incorporate components manufactured from reinforced carbon fiber cloth, particularly in non-rotating applications such as nacelles, bypass ducts, and acoustic panels. The high-temperature performance of certain carbon fiber grades enables their use in moderately heated engine environments while providing significant weight savings compared to metallic alternatives. The thermal stability of reinforced carbon fiber cloth makes it suitable for applications where dimensional stability under temperature cycling is critical.

The acoustic properties of reinforced carbon fiber cloth contribute to noise reduction in aircraft engines, as the material can be engineered to provide specific sound absorption characteristics. By incorporating perforated patterns or specialized weave structures, reinforced carbon fiber cloth can function as both a structural component and an acoustic treatment, reducing overall system complexity and weight while improving passenger comfort and regulatory compliance.

Comparative Analysis with Traditional Materials

Weight Reduction Achievements

The weight reduction potential of reinforced carbon fiber cloth compared to aluminum and steel represents one of its most significant advantages in aerospace applications. Typical weight savings range from 20% to 50% depending on the specific application and design optimization. This weight reduction directly impacts aircraft operating costs through reduced fuel consumption and increased payload capacity, making the higher initial cost of reinforced carbon fiber cloth economically justified over the aircraft's operational lifetime.

Beyond simple weight reduction, reinforced carbon fiber cloth enables design consolidation that eliminates multiple fasteners and joints common in metallic construction. This part consolidation reduces manufacturing complexity, improves structural efficiency, and eliminates potential failure points associated with mechanical fasteners. The ability to create complex shapes in single manufacturing operations further enhances the weight and cost advantages of reinforced carbon fiber cloth in aerospace applications.

Durability and Maintenance Considerations

The corrosion resistance of reinforced carbon fiber cloth provides significant advantages over aluminum in aerospace applications, particularly in marine environments or regions with high humidity and salt exposure. Unlike metallic materials, carbon fiber composites do not suffer from electrochemical corrosion, eliminating the need for protective coatings and associated maintenance procedures. This corrosion immunity extends component service life and reduces lifecycle maintenance costs.

Fatigue performance represents another area where reinforced carbon fiber cloth excels compared to traditional aerospace materials. The absence of crack propagation mechanisms common in metals means that properly designed carbon fiber composite structures can theoretically achieve infinite fatigue life under normal operating conditions. This characteristic reduces inspection requirements and extends service intervals, providing operational advantages that offset the higher initial material costs of reinforced carbon fiber cloth.

Design Optimization and Engineering Considerations

Fiber Architecture Selection

The selection of appropriate fiber architecture in reinforced carbon fiber cloth requires careful consideration of the loading conditions and manufacturing constraints specific to each aerospace application. Balanced weaves provide equal strength in warp and weft directions, making them suitable for applications with multidirectional loading. Unbalanced weaves can be optimized for primary load directions while maintaining adequate strength in secondary directions, enabling more efficient structural designs.

Advanced reinforced carbon fiber cloth architectures include three-dimensional weaves that provide through-thickness reinforcement, addressing one of the traditional weaknesses of laminated composite structures. These 3D architectures improve damage tolerance and impact resistance while maintaining the in-plane properties that make reinforced carbon fiber cloth attractive for aerospace applications. The selection of cloth architecture must balance performance requirements with manufacturing feasibility and cost considerations.

Manufacturing Process Integration

The integration of reinforced carbon fiber cloth into aerospace manufacturing processes requires consideration of handling characteristics, drapability, and compatibility with automated production equipment. The cloth format provides advantages in automated lay-up processes, as it can conform to complex tool surfaces more easily than prepreg tape while maintaining fiber orientation control. This manufacturability advantage becomes increasingly important as aerospace manufacturers seek to increase production rates and reduce labor costs.

Quality assurance in reinforced carbon fiber cloth processing involves monitoring of fiber volume fraction, void content, and cure quality throughout the manufacturing process. Advanced non-destructive testing techniques such as ultrasonic inspection and thermography enable detection of manufacturing defects that could compromise structural performance. The establishment of robust quality control procedures ensures that the performance benefits of reinforced carbon fiber cloth are fully realized in production aircraft components.

Future Developments and Industry Trends

Advanced Fiber Technologies

Ongoing research in carbon fiber technology continues to push the boundaries of what is achievable with reinforced carbon fiber cloth. Higher modulus carbon fibers approaching theoretical limits provide opportunities for even greater weight savings in stiffness-critical applications. Advanced manufacturing techniques such as spread-tow technology enable the production of thinner, more drapable reinforced carbon fiber cloth while maintaining structural performance, opening new possibilities for complex aerospace geometries.

The development of intermediate modulus carbon fibers optimized specifically for reinforced carbon fiber cloth applications represents a significant advancement in balancing performance and cost. These fibers provide improved compression strength and damage tolerance compared to high modulus alternatives while maintaining sufficient stiffness for aerospace requirements. The optimization of fiber properties for cloth applications enables better performance in the final composite structure while potentially reducing material costs.

Sustainable Manufacturing Initiatives

Environmental considerations are driving innovation in reinforced carbon fiber cloth manufacturing and recycling technologies. Advanced recycling processes can recover carbon fibers from end-of-life aircraft components, creating recycled reinforced carbon fiber cloth suitable for secondary aerospace applications. These sustainability initiatives address environmental concerns while potentially reducing material costs as recycling technologies mature and scale up to commercial volumes.

Bio-based precursor materials for carbon fiber production represent an emerging area of development that could enhance the sustainability profile of reinforced carbon fiber cloth. Research into lignin-based and other renewable precursors aims to reduce the environmental impact of carbon fiber production while maintaining the performance characteristics required for aerospace applications. These developments align with industry sustainability goals and regulatory requirements for reduced environmental impact.

FAQ

What makes reinforced carbon fiber cloth superior to traditional aluminum in aerospace applications

Reinforced carbon fiber cloth offers superior strength-to-weight ratios compared to aluminum, typically providing 20-50% weight reduction while maintaining equivalent or better structural performance. The material also exhibits excellent fatigue resistance, corrosion immunity, and design flexibility that enables part consolidation and complex geometries impossible with traditional metallic construction. These advantages translate into improved fuel efficiency, reduced maintenance requirements, and enhanced aircraft performance capabilities.

How does the weave pattern affect the performance of reinforced carbon fiber cloth

The weave pattern in reinforced carbon fiber cloth significantly influences mechanical properties, handling characteristics, and manufacturing requirements. Plain weaves provide maximum stability and balanced properties in both warp and weft directions, while twill and satin weaves offer improved drapability for complex shapes at the potential cost of some mechanical performance. The selection of weave pattern must consider the specific loading conditions, manufacturing processes, and surface finish requirements for each aerospace application.

What quality control measures ensure reliable performance of reinforced carbon fiber cloth in critical aerospace applications

Quality control for aerospace-grade reinforced carbon fiber cloth involves comprehensive testing of fiber properties, fabric construction parameters, and surface treatment effectiveness. Manufacturing quality assurance includes continuous monitoring of weave pattern consistency, fabric weight uniformity, and defect detection through advanced inspection systems. Material certification requires extensive mechanical testing, environmental conditioning, and traceability documentation to ensure compliance with aerospace specifications and regulatory requirements.

How do manufacturing costs of reinforced carbon fiber cloth compare to traditional aerospace materials

While reinforced carbon fiber cloth typically has higher initial material costs compared to aluminum or steel, the total lifecycle cost often favors carbon fiber due to weight savings that reduce fuel consumption and maintenance requirements. Manufacturing costs are influenced by production volume, part complexity, and automation level, with carbon fiber becoming increasingly cost-competitive as manufacturing processes mature and production scales increase. The economic benefits of improved fuel efficiency and reduced maintenance often justify the premium material costs over the aircraft's operational lifetime.

Table of Contents

- Understanding the Composition and Structure of Reinforced Carbon Fiber Cloth

- Manufacturing Processes and Quality Control

- Aerospace Applications and Performance Benefits

- Comparative Analysis with Traditional Materials

- Design Optimization and Engineering Considerations

- Future Developments and Industry Trends

-

FAQ

- What makes reinforced carbon fiber cloth superior to traditional aluminum in aerospace applications

- How does the weave pattern affect the performance of reinforced carbon fiber cloth

- What quality control measures ensure reliable performance of reinforced carbon fiber cloth in critical aerospace applications

- How do manufacturing costs of reinforced carbon fiber cloth compare to traditional aerospace materials