In fields demanding high-performance materials like structural reinforcement and industrial manufacturing, carbon fiber fabric is highly favored for its exceptional strength-to-weight ratio, corrosion resistance, and design flexibility. However, are you aware that carbon fiber fabric comes in unidirectional and bidirectional varieties? They differ significantly in structure, performance, and application scenarios. This article provides a thorough analysis of their core differences and respective advantages, offering clear guidance for your practical selection needs.

I. Unidirectional Carbon Fiber Fabric: Focused Strength in One Direction

Structural Characteristics:

Unidirectional fabric features densely packed carbon fiber tows (e.g., common 12K tows, each containing 12,000 filaments) aligned primarily in one dominant direction (usually the warp direction). The other direction (weft) contains only minimal fine fibers or specialized thermoplastic adhesive threads for fixation. This design concentrates its performance intensely along the fiber alignment axis.

Core Advantages:

Exceptional Uniaxial Strength: Along its primary fiber direction, its tensile strength far exceeds that of ordinary steel (by several times). For example, 12K unidirectional fabric can readily withstand immense tensile loads in its dominant direction, making it ideal for reinforcing tension zones in beams, slabs, and other structures, particularly where the primary load direction is well-defined.

Superior Impregnation: Its relatively simple structure allows the compatible carbon fiber resin (matrix) to penetrate the fiber bundles quickly and uniformly. This ensures a strong bond between the fabric and the substrate, forming an efficient stress-transfer composite system, while also simplifying the installation process.

Outstanding Cost-Effectiveness: The manufacturing process is relatively simpler and uses less raw material compared to bidirectional fabric, resulting in a lower overall cost. This offers significant cost advantages in large-scale, standard reinforcement projects.

Convenient & Flexible Installation: The fabric is soft and easily cut. Installation simply involves applying it along the predetermined load-bearing direction (e.g., tension direction or perpendicular to cracks), requiring no complex skills or heavy machinery. Even on slightly uneven substrate surfaces, high effective bonding rates are achievable. Local air bubbles can be easily remedied via injection syringe repair, shortening project timelines and ensuring quality control.

Key Limitations:

Weak Performance Off-Axis: Perpendicular to the fiber direction, its ability to resist tension, shear, and other forces is very limited. If a structure experiences complex, multi-directional stresses, unidirectional fabric alone may be insufficient for comprehensive reinforcement.

Risk Under Non-Axial Loads: When external forces deviate from the primary fiber direction, unidirectional fabric is more prone to breakage or damage. Using it on irregular structural elements with uncertain or unexpected lateral loading directions carries a risk of reinforcement failure.

II. Bidirectional Carbon Fiber Fabric: The Balanced Multi-Tasker

Structural Characteristics:

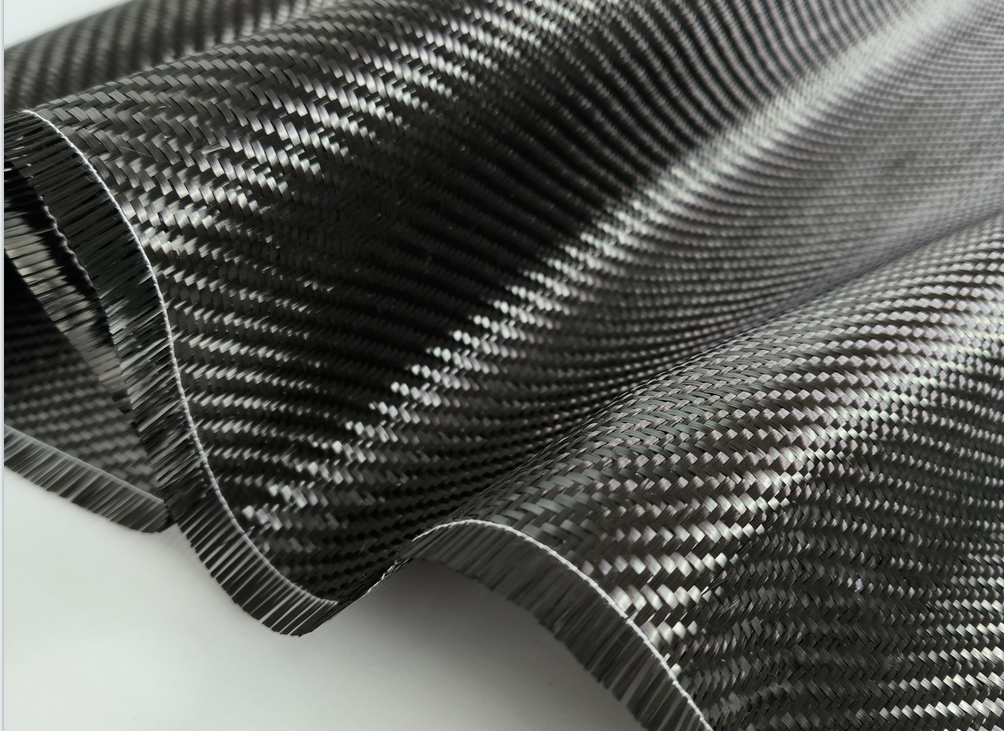

Bidirectional fabric incorporates substantial rovings (carbon fiber bundles) in both the warp and weft directions, woven into a grid structure using techniques like plain, twill, or satin weaves. This design provides relatively balanced mechanical properties in two orthogonal directions.

Core Advantages:

Superior Biaxial Load Capacity: Effectively withstands tension, compression, and even partial shear forces from multiple directions, overcoming the unidirectional fabric's limitation of single-axis dependency. It excels in complex load-bearing structures with unclear primary load paths (e.g., intricate joints, shear walls) or scenarios requiring uniform enhancement of overall stability and load-bearing capacity.

Excellent Conformability to Complex Shapes: The woven structure offers superior flexibility and deformation adaptability, allowing it to conform tightly to complex surfaces like pipes, irregular components, and curved structures. This ensures uniform coverage and reinforcement without dead zones.

Broad Application Scope: Thanks to its balanced biaxial properties and good conformability, its use extends beyond building reinforcement (e.g., historic irregular components, silos) to industrial equipment (parts requiring multi-directional strength) and aerospace (structural components), meeting demands for high performance in multiple directions.

Key Limitations:

Lower Strength Per Single Axis: Despite balanced biaxial performance, its ultimate strength in any single direction is typically lower than that of equivalent unidirectional fabric in its dominant direction. This is because fiber bending and interlacement during weaving partially disperse the inherent strength.

Complex Manufacturing, Higher Cost: The weaving process, requiring precise interlacing of warp and weft yarns, is more complex and demands advanced equipment and technology. This leads to lower relative production efficiency and potentially higher material waste. Consequently, bidirectional fabric is generally more expensive than unidirectional fabric, potentially limiting its use in cost-sensitive projects.

Increased Impregnation Difficulty: The thicker, more intricate woven structure makes it harder for the resin matrix to penetrate rapidly and uniformly into all fiber interstices. This demands higher skill in application techniques (e.g., resin mixing, brushing/vacuum infusion) and operator experience; otherwise, it can compromise bond quality and reinforcement effectiveness.

III. How to Choose Optimally? Context and Loading are Key!

Prioritize Unidirectional Fabric When:

The structural load path is highly defined and uniaxial (e.g., tension zones in beams/slabs for flexural reinforcement).

Extremely high ultimate strength in one specific direction is paramount.

Project budget is constrained, prioritizing high cost-effectiveness.

The substrate surface is relatively flat or simplified installation is required.

Prioritize Bidirectional Fabric When:

Structural loading is complex and multi-directional (e.g., joints, shear walls, silos).

The primary load direction is difficult to define clearly.

Components needing reinforcement have complex, curved geometries (e.g., pipes, domes, historic irregular elements).

Uniform overall enhancement and stability of the structure are critical.

Applications involve industrial equipment, aerospace, or other fields requiring multi-directional high performance.

Conclusion:

Unidirectional carbon fiber fabric is the "Directional Strength Specialist," delivering ultra-high strength and superior cost efficiency when the primary load path is clear. Bidirectional carbon fiber fabric is the "Balanced Multi-Tasker," showcasing its comprehensive coverage and stable load-bearing advantages in complex loading scenarios and irregular structures. A thorough understanding of their distinct characteristics, combined with careful consideration of the specific project's structural form, loading conditions, geometric complexity, and budget, enables the most scientific and efficient selection. This ensures carbon fiber reinforcement technology truly safeguards structural safety and enhances performance.

Trusted Quality Choice - Dr.reinforcement

With years of deep expertise in carbon fiber reinforcement, Dr.reinforcement provides high-performance, reliable unidirectional and bidirectional carbon fiber fabrics, along with professional solutions. Whether you require directional peak strength or need to tackle complex multi-directional challenges, we meet your engineering demands, helping you achieve reliable reinforcement outcomes through optimal investment.

Email:[email protected]

Whats/Tel:+86 19121157199

Hot News

Hot News