Understanding Advanced Composite Materials in Modern Engineering

The realm of composite materials has evolved dramatically over recent decades, with carbon fiber mesh cloth and fiberglass leading the charge in various industrial applications. These revolutionary materials have transformed how we approach construction, automotive design, aerospace engineering, and numerous other fields. As industries continue to demand lighter, stronger, and more versatile materials, understanding the distinct characteristics of these composites becomes increasingly crucial.

In today's competitive market, engineers and manufacturers must make informed decisions about which material best suits their specific needs. Both carbon fiber mesh cloth and fiberglass have carved out their respective niches, each offering unique advantages and specific use cases that deserve careful consideration.

Material Composition and Structure

Carbon Fiber Mesh Cloth Construction

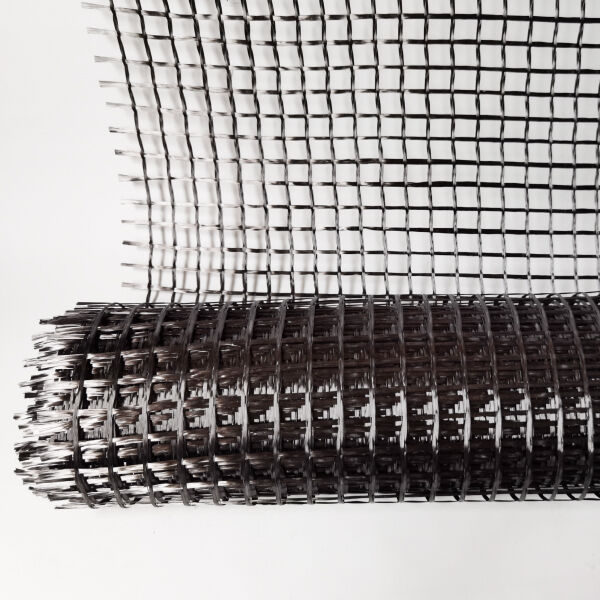

Carbon fiber mesh cloth consists of extremely thin fibers about 5-10 micrometers in diameter, primarily composed of carbon atoms. These fibers are woven into a distinctive mesh pattern that provides exceptional strength and flexibility. The manufacturing process involves carefully aligning carbon molecules in a crystalline structure parallel to the fiber's long axis, creating an incredibly strong material.

The weaving pattern of carbon fiber mesh cloth can be customized to meet specific requirements, with options ranging from plain weave to twill and satin patterns. Each weaving style offers different characteristics in terms of strength, flexibility, and surface finish, making it highly adaptable to various applications.

Fiberglass Composition and Manufacturing

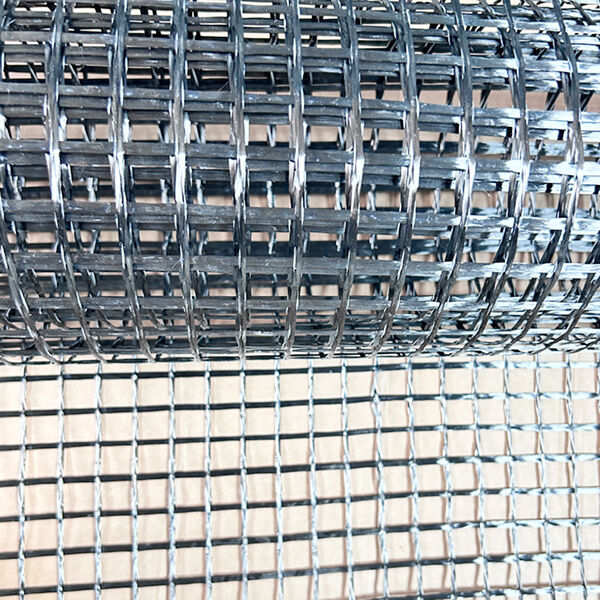

Fiberglass, by contrast, is made from extremely fine fibers of glass, created by extruding molten glass through very small openings. These glass fibers are then woven into a fabric or mat, which can be treated with various resins to create the final composite material. The resulting product offers good strength and excellent insulating properties.

The manufacturing process of fiberglass is generally less complex and more cost-effective than carbon fiber production, making it a more accessible option for many applications. However, this comes with certain trade-offs in terms of performance characteristics.

Performance Characteristics and Properties

Strength-to-Weight Ratio Analysis

Carbon fiber mesh cloth demonstrates superior strength-to-weight properties compared to fiberglass. Typically, carbon fiber constructions are 40% lighter than comparable fiberglass alternatives while offering greater tensile strength. This remarkable efficiency makes it particularly valuable in applications where weight reduction is crucial, such as aerospace and high-performance automotive components.

The exceptional strength of carbon fiber mesh cloth comes from its molecular structure and the way carbon atoms bond together. This results in a material that can withstand tremendous stress while maintaining its structural integrity, often outperforming traditional materials by significant margins.

Durability and Environmental Resistance

When it comes to environmental resistance, both materials have their unique characteristics. Carbon fiber mesh cloth exhibits excellent fatigue resistance and maintains its properties under repeated stress. It's also highly resistant to chemical corrosion and shows minimal thermal expansion, making it ideal for applications requiring dimensional stability.

Fiberglass, while generally more susceptible to fatigue, offers superior resistance to certain environmental factors. It performs particularly well in corrosive environments and can withstand exposure to various chemicals and moisture better than some grades of carbon fiber materials.

Cost Considerations and Economic Factors

Manufacturing and Production Expenses

The production of carbon fiber mesh cloth involves complex processes and expensive raw materials, resulting in higher manufacturing costs compared to fiberglass. The specialized equipment and expertise required for carbon fiber production contribute significantly to its premium pricing. However, advances in manufacturing technology are gradually making it more accessible.

Fiberglass production, being a more established and streamlined process, typically incurs lower manufacturing costs. This cost advantage has made fiberglass the go-to choice for many commercial applications where budget constraints play a crucial role in material selection.

Long-term Investment Analysis

While the initial cost of carbon fiber mesh cloth is higher, its superior durability and performance characteristics often result in better long-term value. The extended service life and reduced maintenance requirements can offset the higher upfront investment, especially in applications where performance is critical.

When calculating total lifecycle costs, factors such as maintenance requirements, replacement frequency, and performance benefits must be considered. In many cases, the premium paid for carbon fiber mesh cloth can be justified through improved efficiency and reduced long-term expenses.

Application Domains and Industry Usage

Aerospace and Aviation Applications

In the aerospace industry, carbon fiber mesh cloth has become indispensable due to its exceptional strength-to-weight ratio. It's extensively used in aircraft components, satellite structures, and space vehicles where weight reduction directly impacts fuel efficiency and operational costs. The material's resistance to fatigue and thermal stability makes it ideal for these demanding applications.

Modern aircraft manufacturers increasingly rely on carbon fiber composites for both structural and aesthetic elements. From fuselage components to interior panels, the material's versatility and performance characteristics continue to drive innovation in aerospace design.

Construction and Infrastructure Projects

The construction industry utilizes both materials extensively, with each finding its optimal applications. Carbon fiber mesh cloth is particularly valuable in structural reinforcement and rehabilitation projects where its high strength and low weight provide significant advantages. Bridge repairs, building retrofits, and seismic upgrades frequently employ carbon fiber solutions.

Fiberglass remains popular in construction applications requiring good insulation properties and corrosion resistance. It's commonly used in building facades, roofing materials, and infrastructure components where cost-effectiveness is a priority without compromising performance.

Frequently Asked Questions

What makes carbon fiber mesh cloth more expensive than fiberglass?

The higher cost of carbon fiber mesh cloth is primarily due to its complex manufacturing process, expensive raw materials, and the specialized equipment required for production. The precise control needed during fiber creation and weaving, along with the high-quality carbon precursors used, contributes significantly to its premium pricing.

How long does carbon fiber mesh cloth typically last compared to fiberglass?

Carbon fiber mesh cloth generally offers superior longevity, often lasting 20-30 years or more when properly maintained. While fiberglass can also be durable, it typically shows signs of degradation earlier, especially under high-stress conditions or extensive environmental exposure. The actual lifespan depends heavily on the specific application and environmental conditions.

Can carbon fiber mesh cloth be repaired if damaged?

Yes, carbon fiber mesh cloth can be repaired, though the process requires expertise and specific techniques. Repairs typically involve carefully removing the damaged area and applying new carbon fiber material with appropriate resins. The repaired section can maintain much of the original strength, though it's crucial to have repairs performed by qualified professionals.