Supporting High-End Manufacturing with "Lightweight Armor"—A Comprehensive Analysis of Carbon Fiber Reinforced Polymer (CFRP)

When it comes to "key materials for high-end manufacturing," many people think of chips and special steel. However, another advanced material is quietly transforming industries such as aerospace, new energy, and high-end equipment—Carbon Fiber Reinforced Polymer (CFRP). Unlike metals, which are widely recognized, CFRP operates more like an unsung hero: airplanes use it to reduce weight and save fuel, wind turbine blades rely on it to withstand wind vibrations, and new energy vehicles utilize it to extend range. As one of China's top three reinforcement brands, Dr. Reinforcement has dedicated ten years to the industry, serving over a million customers with CFRP products that match Toray's quality at half the price! Today, we explore the properties, processes, applications, and localization of this "feather-light, steel-strong" material, and show how you can access high-end materials at a lower cost.

I. Core Characteristics: Not Metal, but Stronger

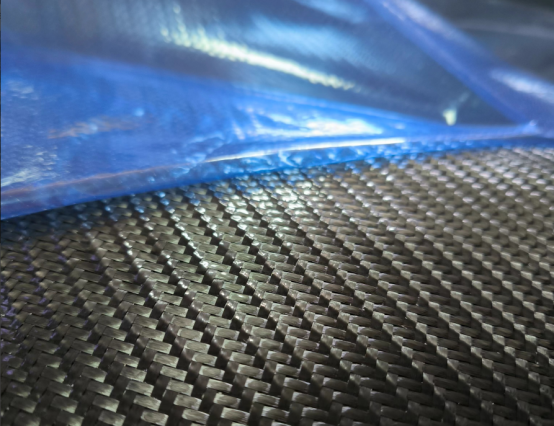

If one word could describe CFRP, it would be "lightweight armor"—composed of a carbon fiber "skeleton" and a resin "binder," it combines the seemingly contradictory advantages of being both light and strong.

Light yet Strong: Density Only One-Fourth That of Steel, Strength Over Ten Times Higher

The density of ordinary steel is about 7.8g/cm³, while CFRP is only 1.63g/cm³. This is equivalent to using the weight of one bottle of water to withstand the pressure of ten. Taking T700-grade carbon fiber as an example, its tensile strength exceeds 3500MPa, more than ten times that of ordinary steel. A clear example is aircraft: the Boeing 787 uses CFRP for fuselage components, making it 20%-30% lighter than traditional aluminum alloys and saving tens of tons of fuel per flight. For new energy vehicles, using CFRP for the body reduces weight by 10%, extending range by 5%.

Dr. Reinforcement's CFRP products adhere to the same process standards as Toray, are ISO-9001 and EU-certified, and match the strength and durability of imported high-end materials—all at 50% lower cost, making "lightweight armor" affordable for more companies!

II. Application Scenarios: From Sky to Ground, These Industries Rely on It

CFRP is not a "niche material" but a "necessity" for high-end manufacturing. Over the past decade, Dr. Reinforcement has served over a million customers, covering industries such as aerospace, wind power, and new energy vehicles, providing customized CFRP solutions and supporting domestic substitution!

1.Aerospace: Weight Reduction Equals "Cost Savings"

The Boeing 787 and Airbus A350 use over 50% CFRP for their fuselages and wings, making them 15% lighter than traditional aircraft. The Long March 5 rocket's engine casing uses CFRP, which is 40% lighter than metal.

Dr. Reinforcement provides high-precision carbon fabric and prepreg for the aerospace sector. Our 8,000-square-meter factory ensures stable supply, and our products have passed rigorous anti-fatigue tests, performing on par with international brands!

2.Wind Power: The "Backbone" of 100-Meter Blades

CFRP enables blades to exceed 100 meters in length, extending their service life from 20 to 25 years.

Major domestic wind power companies have batch-adopted Dr. Reinforcement's domestically produced CFRP main beam materials for blades. The price is only half that of imported materials, the supply cycle is shortened by 50%, and after-sales response is faster!

3.New Energy Vehicles: Range "Booster" + Safety "Shield"

Using CFRP for battery casings can extend range by 10%-15%. The carbon fiber winding layer of hydrogen storage bottles can withstand pressures of up to 70MPa.

Dr. Reinforcement provides lightweight battery pack and hydrogen storage bottle solutions for new energy vehicle companies. With 600,000 repeat customers, our quality is stable, and costs are reduced by 30%!

4.Daily Life and Industrial Applications

From robotic arms to high-end bicycle frames, CFRP has become a "standard feature" in high-end products.

Dr. Reinforcement has deeply cultivated the civilian market for ten years, with products covering industrial reinforcement, sports equipment, medical devices, and more. With 100,000 repeat customers, our title as "King of Cost-Effectiveness" is well-deserved!

III. Why Choose Dr. Reinforcement?

Quality Comparable to Toray: Products are ISO-9001 and EU-certified, with T700-grade carbon fiber strength exceeding 3500MPa.

Half the Price: In-house factory enables large-scale production, reducing intermediate links and directly benefiting customers.

Stable Supply: 8,000-square-meter production base with sufficient inventory to support emergency orders.

Ten Years of Reputation: Serving over a million customers, with 600,000 repeat collaborations—quality that stands the test of time.

Contact Dr. Reinforcement Now for a Customized Lightweight Solution!

Whether in aerospace, wind power, new energy, or industrial and civilian applications, we can provide you with carbon fiber solutions that "match Toray's quality at half the price." A decade-old brand trusted by millions—high-end domestic materials are now within reach!

Whatsapp:+86 19121157199

Email:[email protected]

Hot News

Hot News