The base layer of cement concrete pavement is a critical load-bearing component. Damage to this layer significantly reduces pavement smoothness, induces structural defects, and compromises traffic safety. Traditional repair methods are often plagued by poor durability, extended construction periods, and traffic disruption. Carbon fiber fabric, with its exceptional advantages including ultra-high strength, light weight, corrosion resistance, and ease of installation, has emerged as a premier material in civil engineering reinforcement. Its innovative application in repairing and strengthening deteriorated cement concrete pavement base layers effectively inhibits crack propagation, enhances overall structural integrity and load-bearing capacity, significantly extends service life, and substantially reduces lifecycle maintenance costs. This study, based on an actual project case combined with field monitoring data and theoretical analysis, evaluates the feasibility and effectiveness of carbon fiber fabric reinforcement technology. It encompasses project investigation, solution design and implementation, performance monitoring, and comprehensive benefit assessment, providing authoritative guidance for promoting this advanced technology while demonstrating the technical leadership of the Dr. Reinforcement brand.

1 Project Overview

A major urban arterial road constructed in 2005 spans 8.5 kilometers with a pavement structure consisting of cement concrete surface layer + cement-stabilized macadam base layer + graded gravel subbase. In recent years, due to surging traffic volume and frequent heavy-duty truck traffic, the road developed severe distresses, including extensive cracking in the base layer (crack width: 0.1–5 mm), with some areas exhibiting network-shaped penetrating cracks. Reflective cracks appeared in the surface layer, and decreased smoothness in some sections adversely affected driving comfort and safety. The primary causes of deterioration include long-term traffic loading, material degradation due to complex local climate conditions, and relatively low original design standards. Following comprehensive inspection and assessment, which revealed significantly reduced bearing capacity in most base sections, deflection values exceeding permissible limits in some areas, and high variability in the strength of cement-stabilized macadam with partial low-strength zones, the decision was made to adopt Dr. Reinforcement carbon fiber fabric for base layer reinforcement to restore pavement performance and enhance load-bearing capacity.

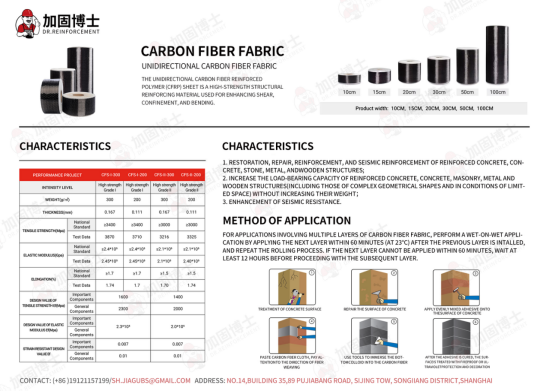

2 Reinforcement Materials: Premium Products from Dr. Reinforcement

This project utilized Dr. Reinforcement high-strength carbon fiber fabric and compatible Dr. Reinforcement epoxy resin adhesive. All material properties exceed standard requirements, ensuring superior performance. The carbon fiber fabric's high tensile strength and elastic modulus effectively restrain crack propagation, while its 1.5% elongation ensures coordinated deformation with the base layer. The adhesive offers high bond strength, excellent aging resistance, and a 45-minute workable time, facilitating construction and guaranteeing long-term performance.

As a leading brand in China's reinforcement materials market, Dr. Reinforcement is trusted for its exceptional quality, competitive pricing, and professional service. All products are certified to ISO-9001 and EU CE standards, making them the ideal choice for reinforcement projects.

3 Construction Process and Quality Control

3.1 Construction Sequence

1.Base Surface Preparation. High-pressure water jetting cleaned the base surface, removing dust, oil, and loose particles. Cracks wider than 0.5 mm were widened to 10–15 mm and deepened to the base bottom manually, followed by cleaning with compressed air and sealing with epoxy mortar. Cracks narrower than 0.5 mm were sanded 50 mm on both sides to roughen the surface, enhancing bond strength. After sanding, compressed air removed all dust.

2.Primer Application. The primer (main agent and hardener mixed per specifications) was evenly applied at 0.2–0.3 mm thickness using a roller brush, ensuring penetration into base pores. At 20–25°C, it cured initially for 1–2 hours (tack-free).

3.Cutting and Pasting Carbon Fiber Fabric. Fabric was cut to design length (crack length + 150 mm extension at both ends). Saturating resin was applied (0.3–0.5 mm thick) on the primed surface. The fabric was laid smoothly from one end, ensuring full contact without wrinkles. A specialized roller expelled air bubbles, ensuring thorough saturation and bond quality. For multiple layers, the second layer was applied after the first layer’s resin cured (12–24 hours, depending on temperature), with a minimum 100 mm overlap.

4.Surface Protection. After curing, a protective coating (0.2–0.3 mm thick) was applied to enhance durability and UV resistance. Upon curing, cement mortar or other surface materials were applied as needed to restore functionality.

3.2 Quality Control Measures

Materials were inspected for certificates and test reports upon delivery. Carbon fiber fabric was sampled (3 groups per 500 m²) for tensile strength testing; adhesive was sampled (5 groups per 200 L) for bond strength testing. Non-compliant materials were rejected. Process inspections ensured base smoothness (≤3 mm), primer thickness (0.2–0.3 mm), fabric overlap (≥100 mm), and resin saturation (98%). Temperature and humidity were recorded hourly; construction proceeded only at 5–35°C and humidity ≤85%. Low temperatures required warm air to maintain 10–15°C; high temperatures necessitated shading to keep below 30°C. Adhesive was used within 2 hours. Acceptance testing involved a 200 g hammer (20 test points per 10 m²); delamination exceeding 100 cm² required rework. Three cores per 500 m² were tested for bond strength; values below 2.5 MPa triggered doubled sampling. After approval, assessment reports were issued for handover.

4 Reinforcement Effectiveness and Benefit Analysis

4.1 Load-Bearing Capacity Improvement

Monitoring data (deflection, base strain, crack development) demonstrated significant improvement. Pre-reinforcement average deflection was 52 (0.01 mm), exceeding the design limit of 30 (0.01 mm). One week post-reinforcement, it dropped to 28 (0.01 mm) and stabilized at 25 (0.01 mm), a 55.2% reduction in representative deflection value, indicating fundamental enhancement of load-bearing capacity. Base strain near cracks decreased substantially, with reduced correlation to load, confirming effective stress distribution and increased overall stiffness. Existing cracks showed minimal propagation, and no new cracks formed, validating structural integrity preservation. Overall, Dr. Reinforcement carbon fiber fabric comprehensively improved load-bearing capacity and durability through deflection reduction, optimized strain distribution, and crack inhibition.

4.2 Economic Benefits Analysis

The Dr. Reinforcement solution required only one month of construction, compared to three months for conventional overhaul, reducing direct costs by 3.6 million RMB (total cost: 3.2 million RMB). Shorter duration minimized traffic disruption and management expenses. Over five years, traditional methods would require 1–2 intermediate repairs (costing 1.5–3 million RMB), whereas the Dr. Reinforcement solution only needs routine maintenance (under 0.3 million RMB). Improved smoothness also lowers vehicle wear, fuel consumption, and accident rates, generating substantial indirect benefits. Despite higher material costs, the solution offers significant overall economic advantages and promising application prospects.

5 Conclusion

Dr. Reinforcement carbon fiber fabric effectively bears tensile stress and inhibits crack growth. Project verification confirmed substantial reduction in pavement deflection and base strain, significantly enhancing load-bearing capacity. Economically, it saves direct costs and reduces long-term maintenance expenses compared to traditional methods. In summary, Dr. Reinforcement technology is feasible, efficient, and economical, providing a reliable solution for deteriorating cement concrete pavement base layers and warranting broad adoption.

Dr. Reinforcement specializes in manufacturing carbon fiber fabric and has participated in numerous reinforcement projects across China, earning widespread customer acclaim. We consistently deliver premium quality at competitive prices! All products are ISO-9001 and CE certified. If you are seeking high-quality carbon fiber fabric, contact us for your exclusive discount!

Whatsapp:+86 19121157199

Email:[email protected]

Hot News

Hot News