Recent engineering practices demonstrate that carbon fiber reinforced polymer (CFRP) strengthening technology, with its high-efficiency construction and significant comprehensive benefits, has become a vital choice for building structure strengthening and rehabilitation. This technique is applicable to the reinforcement and repair of various structural elements, including beams, slabs, columns, roof trusses, tunnels, and other concrete structures.

Core Material Properties

Carbon fiber fabric, as a high-performance composite material, possesses the following outstanding characteristics:

Ultra-High Strength: Tensile strength can exceed 10 times that of carbon steel plates.

Lightweight and High Strength: Low unit weight, adding almost no additional load to the structure.

Excellent Durability: Superior resistance to corrosion and fatigue, good performance across temperature variations (cold/heat), stable properties, effectively extending the service life of strengthened structures.

Good Construction Adaptability: Flexible texture, facilitating on-site cutting and bonding to complex curved surfaces.

Main Technical Advantages

Convenient and Efficient Construction: Relatively simple procedures; requires no large machinery or fixed equipment; primarily relies on manual operation; fast construction speed; minimal disruption to the site.

Easy Quality Assurance: The material is soft and bonds easily, ensuring close adhesion to the substrate and reliable construction quality.

Good Waterproofing Performance: The epoxy resin adhesive system used has strong penetrability, effectively sealing micro-cracks in the concrete substrate and enhancing waterproofing effects.

Outstanding Corrosion Resistance: Both the carbon fiber itself and the epoxy resin system exhibit excellent resistance to chemical corrosion, making it suitable for harsh environments.

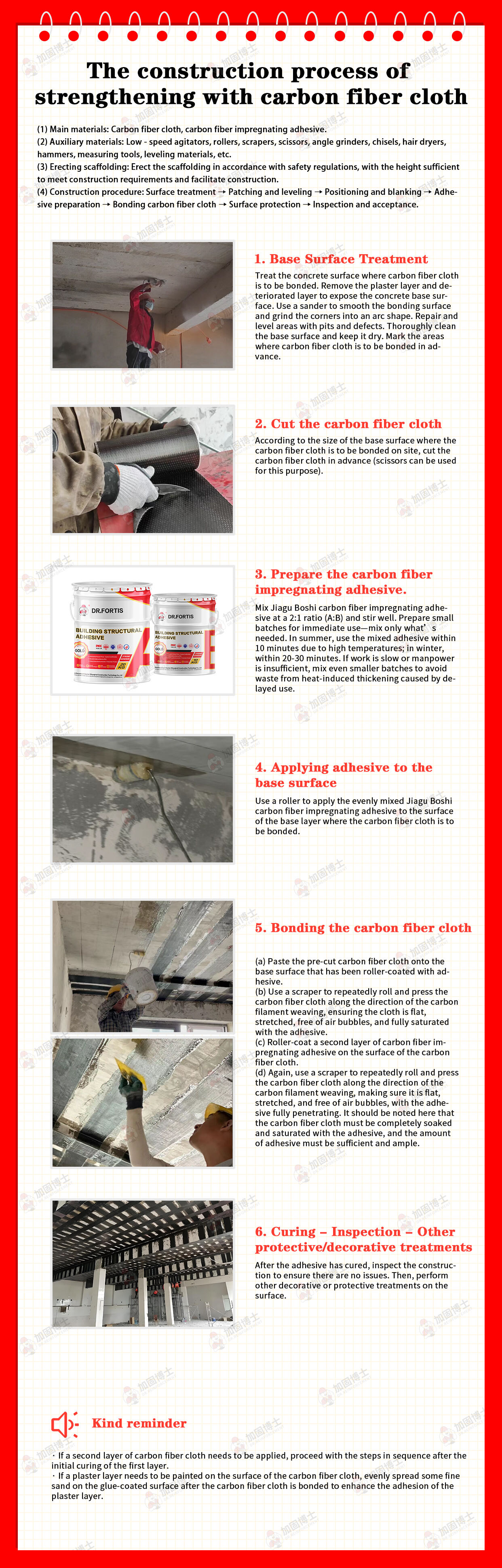

Standardized Construction Process

Unloading: Where possible, unload or reduce the load on the component to be strengthened prior to strengthening.

Layout and Marking: Precisely mark the CFRP or steel plate bonding locations (e.g., beam bottom, beam side, shear wall) on the areas requiring strengthening according to design specifications.

Substrate Surface Preparation:

Chisel off Plaster/Render Layer: Remove the surface plaster layer within the marked area down to the sound structural concrete layer.

Grinding and Leveling: Use an angle grinder with a sanding disc to grind the concrete substrate surface, removing laitance and loose particles to ensure flatness.

Cleaning and Dust Removal: Thoroughly remove dust generated by grinding (recommended: compressed air or industrial vacuum cleaner) to ensure the substrate is clean and dry.

Applying Primer: Evenly apply a thin coat of low-viscosity epoxy primer to the prepared substrate surface, allowing it to fully penetrate the concrete pores.

Substrate Leveling: Fill depressions, holes, and uneven areas on the substrate using epoxy mortar (or repair putty) to ensure a flat bonding surface.

Bonding Carbon Fiber Fabric:

Apply an even coat of epoxy saturant/resin onto the leveled and cured substrate surface.

Lay the pre-cut carbon fiber fabric smoothly onto the resin layer. Roll firmly along the fiber direction to expel air bubbles, ensuring the resin saturates the fibers and achieves full contact..

Repeat this step for multiple layers if required

Hot News

Hot News