Dalam bidang pengukuhan struktur, kain gentian karbon telah menjadi bahan utama yang banyak digunakan disebabkan oleh kelebihan ketara seperti ringan, kekuatan tinggi, serta kecekapan pembinaan (4-5 kali lebih cepat berbanding pengikatan plat keluli). Prinsip pengukuhan kain ini melibatkan proses melekatkan kain tersebut ke permukaan anggota struktur konkrit menggunakan adhesif resins yang bertindak sebagai perekat berprestasi tinggi, membolehkan kekuatan tegangan gentian karbon yang luar biasa dapat dimanfaatkan sepenuhnya untuk meningkatkan keupayaan dan kekuatan anggota berkenaan.

Walau bagaimanapun, pasaran dipenuhi dengan kain gentian karbon palsu, yang biasanya diperbuat daripada gentian basalt yang diwarnakan, gentian aramid, atau pengganti serupa. Kualiti yang rendah ini produk jauh lebih rendah daripada tahap prestasi piawaian. Ia tidak sahaja gagal mencapai kesan pengukuhan yang diingini, malah turut membawa risiko keselamatan yang serius, berpotensi menyebabkan kemalangan kejuruteraan. Oleh itu, penting untuk membezakan secara tepat kain gentian karbon tulen daripada yang palsu.

Berikut adalah 7 kaedah praktikal untuk mengenal pasti kain gentian karbon tulen:

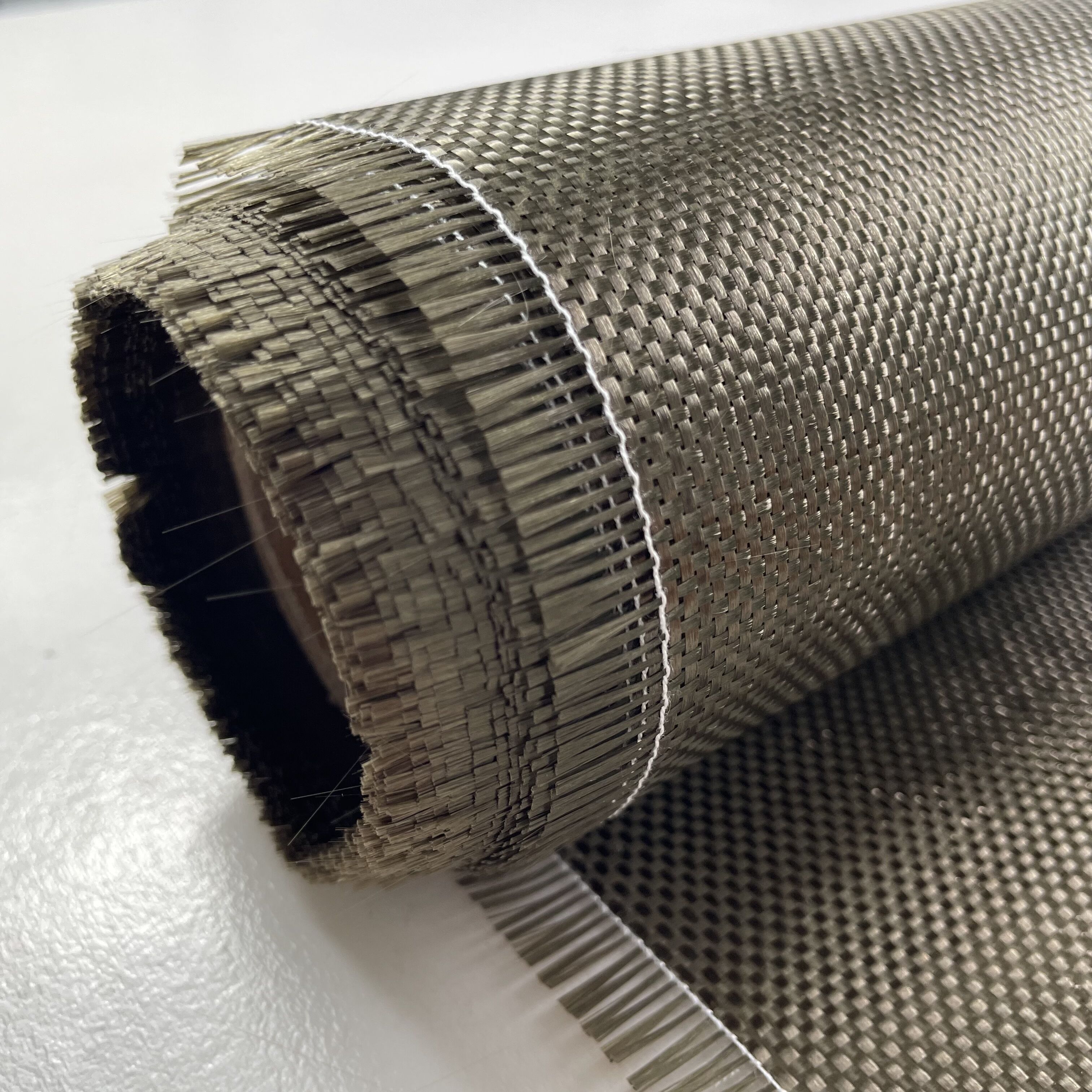

1、Periksa Penampilan:

Tulen: Jalinan benang pakan dan benang lusi yang kemas, bebas daripada kecacatan ketara seperti benang lusi patah, benang pakan patah, atau benang pakan hilang. Helaian gentian karbon berwarna hitam legam dengan kilapan, memberi rasa lembut dan ringan apabila disentuh, serta memperlihatkan taburan helaian yang sekata.

Palsu: Warna kusam dan kering, selalunya memperlihatkan penyerapan warna yang tidak sekata (terutamanya ketara pada imitasi gentian basalt atau aramid yang diwarnakan).

2、Semak Saiz & Berat:

Tulen: Sisihan panjang ≤ 1.5%, sisihan lebar ≤ 0.5%. Berat kawasan unit memenuhi piawaian dengan tepat; spesifikasi biasa adalah 200g/m² (ketebalan kira-kira 0.111 mm) dan 300g/m² (ketebalan kira-kira 0.167 mm). Berat adalah tepat dan mencukupi.

Palsu: Sisihan dimensi yang besar, biasanya kurang berat.

3、Asli (untuk Pengukuhan Struktur): Ditenun menggunakan serat karbon kecil 12k, memastikan penyerapan resin dan kekuatan ikatan yang baik.

Palsu: Untuk mengurangkan kos, biasanya menggunakan tow yang lebih besar (15k, 18k, 24k, atau malah 36k, 48k) yang disalahlaporkan sebagai 12k. Tow yang besar menghalang penyerapan, menghasilkan kualiti ikatan yang buruk dan membawa risiko yang sangat tinggi dalam pengukuhan struktur.

4、Uji Ketahanan Api (Operasi Dengan Berhati-hati):

Tulen: Mempunyai rintangan suhu tinggi yang sangat baik. Tidak berkerut atau melebur apabila terdedah kepada api. Boleh menghasilkan bunga api kecil semasa terbakar tetapi memadamkan diri sendiri apabila api dialihkan , dengan bentuknya kekal kebanyakannya tidak berubah. Tidak menunjukkan perubahan ketara walaupun terdedah dalam jangka masa yang lama.

Palsu: Kerap kali mudah terbakar. Cenderung untuk melengkung, melebur, atau menghasilkan abu berwarna tidak normal (contohnya, kuning pucat, putih) selepas terbakar. ( AMARAN: Ujian ini membawa risiko yang semulajadi. Patuhi langkah keselamatan kebakaran dengan ketat! )

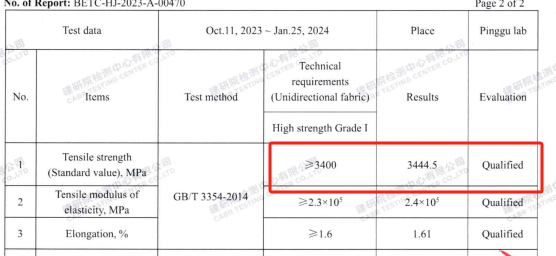

5、Ukur Kekuatan Tarikan:

Tulen: Kekuatan tarikan yang sangat tinggi. Mengikut Piawaian Kebangsaan China GB 50367 "Kod Rekabentuk Penguatan Struktur Konkrit", kain gentian karbon Gred I mesti mempunyai kekuatan tarikan ≥ 3400 MPa , modulus keanjalan tarikan ≥ 230 GPa (2.3×10^5 MPa), dan pemanjangan pada putus ≥ 1.6%. Sukar atau mustahil untuk dipatahkan dengan tangan.

Palsu: Kekuatan tarikan jauh lebih rendah daripada piawaian; sering kali boleh dipatahkan dengan tangan atau dengan daya yang minima.

6、Sahkan Laporan Pemeriksaan:

Tulen: Mesti mempunyai sah laporan ujian bersijil yang dikeluarkan oleh institusi pengujian berwibawa, untuk membuktikan kepatuhan terhadap piawaian seperti GB 50728 "Kod Teknikal untuk Penilaian Keselamatan Bahan Pengukuhan Struktur Kejuruteraan" dan CECS 146 "Spesifikasi Teknikal untuk Pengukuhan Struktur Konkrit dengan Lapisan Polimer Diperkukuhkan Serat Karbon". Laporan ini mesti mengesahkan parameter utama seperti sifat mekanikal (kekuatan tegangan, modulus keanjalan) dan ketahanan.

Palsu: Tiada laporan ujian piawaian kebangsaan/industri yang sah dan berasaskan kepatuhan, atau laporan mengandungi data yang meragukan.

7、Bandingkan Harga & Kualiti:

Tulen: Kos bahan mentah yang tinggi dan proses pengeluaran yang kompleks serta ketat bermaksud harga pasaran tidak boleh terlalu rendah . Prestasinya (terutamanya kekuatan) adalah berbagai kali ganda berbanding gentian tiruan.

Palsu: Sering menarik pelanggan dengan harga jauh di bawah paras pasaran yang munasabah . Boleh menggunakan kaedah penjimatan kos seperti menenun campuran (mencampurkan gentian lebih murah) atau mengurangkan penggunaan bahan (mengurangkan jumlah tows). Amaran harga terlalu rendah!

Kesimpulan: Memilih fabrik gentian karbon berkualiti tinggi adalah asas untuk memastikan keselamatan dan keberkesanan projek pengukuhan. Ia penting untuk mengaplikasikan dengan teliti tujuh kaedah di atas untuk pengesanan. Jangan sekali-kali mengorbankan kualiti demi harga yang lebih rendah. Memilih produk palsu boleh membawa kesan yang tidak berbalik dan serius, di mana kosnya jauh melebihi penjimatan. Sentiasa pilih produk daripada sumber yang boleh dipercayai, disokong oleh laporan ujian berwibawa dan telah terbukti mematuhi piawaian prestasi, untuk memastikan keselamatan jangka panjang struktur bangunan.

Berita Hangat

Berita Hangat