When you pick up a carbon fiber product, you might only see a smooth black surface. But under a microscope, it reveals an orderly microcosm. The root of this miraculous material’s extraordinary performance—capable of withstanding the weight of a tank and resisting intense fire—lies hidden within its unique internal structure. Today, let’s step into this microscopic world and decipher the structural code of carbon fiber.

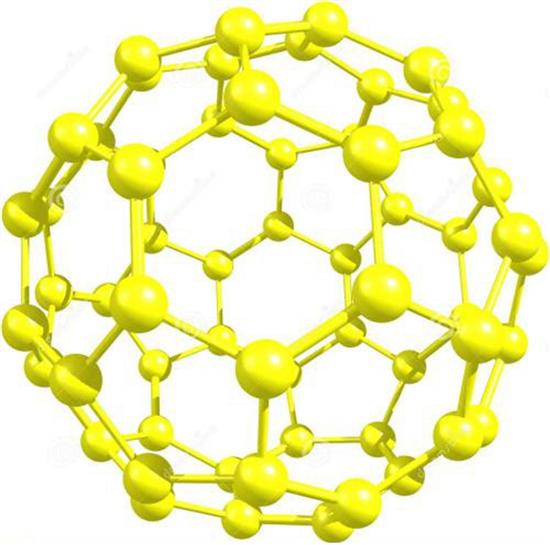

The “Precision Formation” of Carbon Atoms

At the nanoscale, carbon fiber showcases an exquisite “atomic arrangement performance.” Carbon atoms form regular hexagonal grids—a honeycomb-like structure scientists refer to as graphitic layers.

These layers align along the fiber’s length at specific angles, resembling a “spiral staircase.” This arrangement is key to carbon fiber’s strength: when force is applied, the orderly carbon atoms efficiently distribute stress, preventing localized failure. In contrast, the relatively disordered atomic structure of ordinary steel is far less resilient.

The bonding between graphitic layers is equally remarkable. Within each layer, carbon atoms are linked by strong covalent bonds, while weaker van der Waals forces connect the layers. This unique combination allows carbon fiber to balance tremendous tensile strength with flexibility, resisting fracture even under significant bending.

From Fiber to Composite: A Structural Evolution

Individual carbon filaments are incredibly thin (5–10 micrometers), too delicate for direct use. To become practical, they undergo two critical stages of structural enhancement:

Filament Bundling: Thousands of single filaments are aligned into a unified bundle. A standard 12K carbon fiber bundle (containing 12,000 filaments) measures just 3 mm in diameter yet can support 500 kg—enough to lift an adult buffalo.

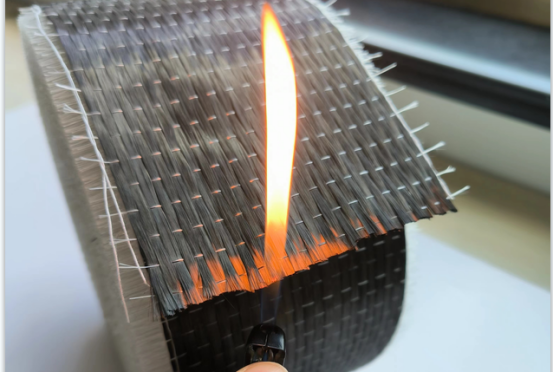

Composite Reinforcement: The bundles are combined with resins, metals, or ceramics to form carbon fiber composites. In the most common type—carbon fiber-reinforced polymer—the resin acts as a protective adhesive, binding the fibers and evenly distributing external forces across each filament. This synergy mirrors reinforced concrete: carbon fibers provide strength, while the matrix material fills and stabilizes the structure.

By selecting different matrix materials (e.g., ceramics for heat resistance, metals for conductivity), composites can be tailored for extreme environments—from deep-sea to aerospace applications.

Performance Through Structure: The “Superpowers” Explained

Every exceptional trait of carbon fiber stems from its microstructure:

Lightweight Secret: Tight atomic packing with microscopic interlayer gaps results in a density of just 1.7 g/cm³—far lower than steel (7.8 g/cm³) or aluminum (2.7 g/cm³).

Heat Resistance: Strong carbon-carbon covalent bonds require temperatures above 3000°C to break, far exceeding the melting point of iron (1538°C). In oxygen-free environments, carbon fiber remains stable up to 2500°C, making it ideal for rocket nozzles.

Corrosion Immunity: The inert graphitic structure resists reactions with acids, alkalis, and other corrosive agents, outperforming metals prone to rust or oxidation.

Conductivity: Electrons move freely along the graphitic layers, enabling electrical conductivity (~1/10 that of copper)—useful for antistatic applications or even replacing metal wires in specific scenarios.

Optimizing Structure: The Path to Superior Performance

At Reinforcement Doctor, we leverage decades of expertise to refine carbon fiber’s microstructure for peak performance. Key strategies include:

Enhanced Graphitization: Processing fibers at 2000–3000°C improves graphitic layer alignment and size, boosting strength and stiffness. Our products rival top-tier materials like Japan’s T1100 grade (7000 MPa tensile strength—a hair-thin filament holding 50 kg).

Precision Orientation Control: Applying tension during production minimizes the alignment angle between graphitic layers and the fiber axis (often below 10 degrees), maximizing axial strength. Our ultra-high-modulus fibers achieve elastic moduli exceeding 900 GPa, over 10 times that of steel.

With 20+ years of innovation, our in-house factory (8000 m²) utilizes German Dornier looms and skilled weavers to ensure uniform tension, zero bubbling, and consistent quality. Over 1 million global customers trust us—nearly half are repeat clients—making us a top-3 leader in China’s reinforcement sector.

Competitive pricing, proven reliability, and tailored solutions for diverse environments: that’s the Reinforcement Doctor advantage.

Need carbon fiber fabrics that deliver? Contact us today for samples, technical support, and custom projects.

Whatsapp:86 19121157199

Email:[email protected]

Reinforcement Doctor: Engineering Trust, One Fiber at a Time.

Hot News

Hot News