The Early Exploration of Carbon Fiber: Budding and Stagnation

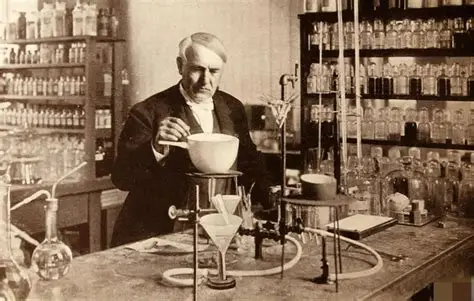

The origin of carbon fiber can be traced back to the 1880s when it was used as a filament material. Thomas Edison and Joseph Swan patented carbon filaments made from bamboo and cotton thread, respectively. However, with the popularization of tungsten filament bulbs, carbon filaments were replaced due to inferior efficiency and lifespan, leading to near stagnation in carbon fiber technology development for decades thereafter.

During World War II, Union Carbide began researching carbon fiber using rayon as a precursor and produced carbon fiber fabric usable for rocket nozzle and heat shield tests in 1958 via high-temperature graphitization. However, due to a lack of optimized stretching processes, its mechanical properties were poor, limiting commercial application.

The 1960s: Multi-Nation Competition and Technological Breakthroughs

In the early 1960s, Japan, the United States, and the United Kingdom almost simultaneously commenced research on high-strength, high-modulus carbon fiber. In 1960, American scientist R. Bacon produced graphite whiskers using a pressure arc method; although not commercialized, it attracted attention from the U.S. Air Force. The same year, Japan's MITI initiated a collaborative research program with companies like Toray and Nippon Carbon to develop polyacrylonitrile (PAN)-based carbon fiber. Akio Shindo published results in 1961, producing samples with three times the performance of rayon-based carbon fiber, but this received little attention in Western academia.

The UK's Royal Aircraft Establishment (RAE) began research in 1963 and accelerated development after learning of the Japanese Achievement, developing a PAN-based carbon fiber process with doubled performance within six months. Key breakthroughs included stretching the PAN precursor during oxidation to enhance molecular orientation, optimizing heat treatment processes, and developing an electrolytic oxidation method to improve fiber-resin bonding. This technology was licensed to three British companies: Courtaulds, Morgan Crucible, and Rolls-Royce.

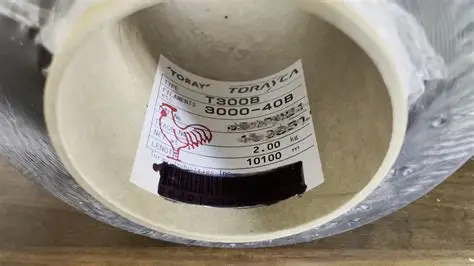

Rolls-Royce used carbon fiber for the RB211 engine blades, but failure during bird strike tests contributed to the company's bankruptcy, severely impacting the UK carbon fiber industry. Meanwhile, Japan's Toray introduced Torayca T300 carbon fiber in 1971, which became a foundational material for first-generation composites and entered the global market through technology exchange agreements.

1970–1989: Application Expansion and Cost Reduction

Starting in the 1970s, carbon fiber applications gradually expanded from aerospace to sporting goods and industrial fields. As processes advanced, its production cost dropped from £200 per kg in 1970 to £20–80 per kg in 1980. Japanese companies, leveraging technological optimization and capacity expansion, gained dominance. Companies like Toray and Toho Rayon successfully promoted carbon fiber in consumer markets such as golf clubs and fishing rods.

In the 1980s, carbon fiber was used in secondary structures of aircraft like the Boeing 757/767. A 1987 U.S. Department of Defense requirement mandating 50% domestic production of carbon fiber and precursors triggered a wave of domestic investment but later led to overcapacity. Japanese firms deepened their global footprint through joint ventures and factory establishments, accounting for nearly half of global carbon fiber production by the late 1980s.

The 1990s: Post-Cold War Challenges and Transformation

The end of the Cold War led to a sharp reduction in defense orders, causing U.S. carbon fiber demand to fall by approximately 60% between 1990–1991, forcing many manufacturers to halt production or exit the market. In contrast, Japanese companies expanded capacity against the trend and strengthened their global position by acquiring plants in Europe and America. In 1993, the Clinton administration launched the Technology Reinvestment Project (TRP), supporting the application of composites in civil infrastructure and aerospace, aiding the gradual recovery of the U.S. industry.

Concurrently, the use of carbon fiber grew in industrial sectors like wind turbine blades and automotive components, while new technologies like thermoplastic composites and pitch-based carbon fibers injected fresh momentum into the industry.

1990–1995: Turbulent Adjustment and Reshaping the Landscape

Global carbon fiber annual sales during this period were approximately 8,000 tons, but regional demand structures differed significantly: the U.S. market was dominated by aerospace, while Asia was led by sporting goods. U.S. defense budget cuts caused severe overcapacity; by 1991, half of the national capacity was idle, and companies like Courtaulds and BASF exited the market.

Japanese companies continued to expand, with firms like Toray and Mitsubishi Rayon entering European and American markets through mergers and acquisitions. By 1995, Japan controlled 62% of global carbon fiber capacity, establishing a clear advantage.

Recovery and New Prospects

After 1995, with increasing demand for lightweight materials in civil aviation aircraft and continued growth in wind power and sporting goods markets, the global carbon fiber industry gradually recovered. U.S. companies, leveraging the TRP project to reduce technical costs, returned to a growth track; Europe became more reliant on foreign investment after local exits. In the future, with rising demand for lightweight materials in emerging fields like electric vehicles and new energy, carbon fiber is expected to find broader application space.

Conclusion

Carbon fiber's journey from a laboratory material to a key raw material in multiple fields involved technological breakthroughs, market fluctuations, and international competition. Japan established a leading position through continuous technological investment and market expansion, the U.S. gradually regained competitiveness with policy support, and Europe faced structural adjustments. In the future, as costs decline and new application scenarios emerge, carbon fiber is poised to play a more important role in green energy, transportation, and other fields.

Harnessing a Century of Material Science, Fortifying Today's Foundations

From the scientific exploration of the 19th century to today's cutting-edge applications worldwide, the evolution of carbon fiber is a history of relentless pursuit of strength and lightness. We honor this dedication and infuse it into every fiber we produce.

Dr. Reinforcement deeply understands the heritage and innovation of carbon fiber technology. We not only possess an 8,000-square-meter modern production base but also have the robust capacity to produce 50,000 tons of carbon fiber fabric daily. This ensures stable and reliable reinforcement solutions for millions of customers globally, from major infrastructure projects to residential safety improvements.

Our entire product line complies with ISO-9001 International Quality System and CE EU certification, meeting world standards. The market is the ultimate test—selective repurchase by nearly half of our customers is the most powerful endorsement of our "absolutely guaranteed quality" promise.

Choosing Dr. Reinforcement means selecting:

Profound Technical Heritage: We stand at the forefront of materials science, allowing historical Accumulate to empower your projects.

Trustworthy Reliability: International dual certifications ensure peace of mind with every reinforcement.

Extensively Proven Excellence: Millions of global customers and a near-50% repurchase rate are testaments to trust.

No matter the challenge your project faces, Dr. Reinforcement has a carbon fiber fabric solution to provide the sturdiest support.

Contact Dr. Reinforcement now, and let us inject unshakable strength into your project with our capability!

Emai:[email protected]

Whatsapp:86 19121157199

Hot News

Hot News