Carbon fiber fabric — known as the “black gold material” — is a high-tech reinforcement product made from continuous carbon fiber filaments through specialized weaving processes, forming unidirectional or bidirectional woven composites. It is not only soft and easy to cut but also conforms tightly to various structural surfaces. When used with dedicated impregnating resin and cured, it forms an ultra-high-strength composite that significantly enhances the component’s load-bearing capacity and durability.

However, wrinkles and blisters during construction are not only common quality defects but also “hidden killers” that seriously affect reinforcement performance and even structural safety. They lead to stress concentration, reduce load-transfer efficiency, and directly threaten project safety.

Want to completely avoid these issues? Dr. Reinforcement shares professional tips and a systematic guide to the entire construction process to help you achieve a perfect carbon fiber reinforcement layer!

I. Root Causes: Why Do Wrinkles and Blisters Occur?

1、 Inadequate Surface Preparation

Insufficient flatness: Failure to grind down to a solid aggregate layer or to round off corners.

Surface defects: Unrepaired honeycombs, pitting, or cracks forming hidden voids.

Inadequate cleaning: Residual dust, oil, or other contaminants affecting adhesion.

2、 Improper Adhesive Application

Incorrect ratio: Not following the manufacturer’s mixing instructions, compromising adhesive performance.

Insufficient or uneven adhesive: Too little adhesive or uneven spread leading to poor fiber impregnation.

Incorrect application: Irregular brushing sequence or direction causing uneven adhesive thickness.

3、 Incorrect Carbon Fiber Fabric Installation

Careless placement: Fabric not laid smoothly, resulting in curls or slack.

Inadequate rolling: Not enough force, too few passes, or incorrect technique; adhesive fails to fully saturate fibers.

Poor handling of special areas: No additional treatment for corners or curved surfaces, leading to wrinkles and bulges.

Ineffective air removal: Trapped air forming blisters.

4、 Environmental and Material Factors

Unsuitable temperature/humidity: Affecting adhesive curing behavior.

Damp substrate: Moisture trapped under the adhesive layer.

Material defects: Loosely woven fabric, high stiffness, or poor-quality raw filaments.

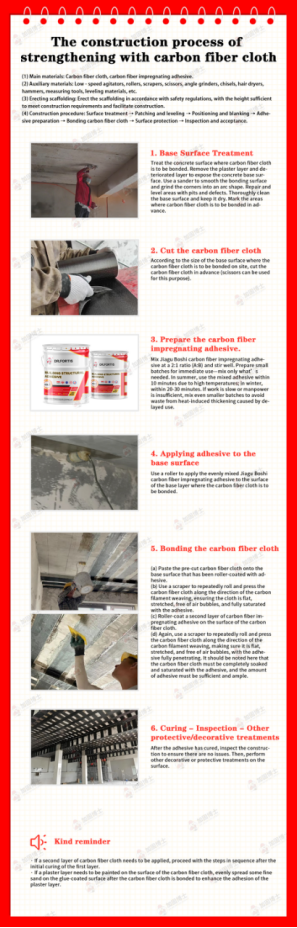

II. Systematic Solutions: Perfect Reinforcement Through Detail-Oriented Construction

1. Surface Preparation: Laying the Foundation

Precision grinding: Use an angle grinder to expose fresh aggregate and round all corners.

Defect repair: Fill holes and cracks with compatible leveling compound to ensure a continuous, flat surface.

Thorough cleaning: Remove dust with an oil-free air blower, then wipe with acetone/alcohol for a clean, dry surface.

2. Primer and Leveling: The Critical Middle Step

Mix primer strictly per ratio, apply thinly and evenly for an absolutely flat base.

3. Impregnating Resin Application: Precision and Efficiency

Weigh accurately and mix thoroughly until uniform in color.

Apply sufficient adhesive: Coat both concrete substrate and carbon fabric; ideal when resin squeezes out from the sides under pressure.

“Mounding” technique: Apply slightly more resin in the center to help squeeze out air during rolling.

4. Fabric Installation and Rolling: Skill and Patience

Two-person teamwork: One holds the roll, one guides the fabric to avoid kinks.

Roll multiple times, with force, inside out: Use a specialized roller for 3–5 passes to ensure full impregnation and air removal.

Special area treatment: Use corner rollers for edges; add supports or clamps for beams to prevent sagging.

III. Choose the Right Materials: Work Efficiently|Dr. Reinforcement Supports You

Good techniques matter, but high-quality materials are fundamental. Dr. Reinforcement’s carbon fiber fabrics and adhesives prevent blisters and wrinkles from the source:

Internationally certified: ISO 9001 & CE EU certified — guaranteed quality.

Precision weaving: German Dornier automated production lines ensure uniform tension and prevent bulging.

Fully automated adhesive production: Accurate ratios and stable curing performance.

10,000㎡ factory with decade-long expertise: Over 1 million global customers served.

Top-tier brand recognition: Ranked among Top 3 Strengthening Material Brands in China 2024.

Choosing Dr. Reinforcement means choosing peace of mind and reliability. We provide not only products but also professional technical support and construction guidance, helping you deliver safe, compliant, and high-quality reinforcement projects!

Contact Dr. Reinforcement now for factory-direct prices and technical manuals! Let us help you achieve perfect construction and efficient delivery!

Email:[email protected]

Whatsapp:86 19121157199

Hot News

Hot News