In the field of construction engineering, "reinforcement" has always been a critical aspect of ensuring structural safety. From the renovation of old buildings to the upgrading of bridge load-bearing capacity, from the transformation of industrial plants to post-disaster structural repairs, the choice of reinforcement materials directly determines project quality and service life. With the evolution of material technology, carbon fiber composite materials have emerged as a powerful alternative with their "lightweight, high-strength, and durable" properties, fiercely competing with traditional reinforcement materials such as steel bars, steel plates, and concrete. Today, we compare these two from three dimensions—performance, application, and economic efficiency—to see who comes out on top in this "clash of the old and the new."

I. Material Properties: From "Heavy Load-Bearing" to "Lightweight Empowerment"

To understand the differences between the two, we must start with their fundamental nature. Traditional reinforcement materials are mostly based on a "gravity-based" design, relying on their own weight and stiffness to resist external forces. In contrast, carbon fiber materials use a composite structure of "high-strength fibers + resin matrix" to achieve a breakthrough in "lightweight high strength."

Traditional Reinforcement Materials: Mature but Limited

Steel Bars/Steel Plates: As the most classic reinforcement materials, steel bars and plates offer the advantages of "intuitive strength and mature construction techniques." They can be integrated with the original structure through welding and anchoring. However, their drawbacks are also significant—excessive weight (steel density ≈ 7.85g/cm³) adds additional load to the structure; they are prone to corrosion, requiring anti-corrosion treatment in humid or acidic/alkaline environments, which increases long-term maintenance costs; and on-site cutting and welding are necessary during construction, requiring ample workspace and generating significant noise and dust pollution.

Sprayed Concrete: Commonly used for wall and tunnel lining reinforcement, it enhances load-bearing capacity by increasing structural thickness. However, it is bulky and heavy (density ≈ 2.4g/cm³), significantly increasing the cross-sectional size of the structure, which may reduce usable space. Additionally, it is prone to shrinkage cracks during hardening, requires reinforcement with steel mesh, and has a long construction cycle.

Carbon Fiber Composite Materials: Lightweight Yet Stronger

Carbon fiber reinforcement materials mainly include carbon fiber fabric and carbon fiber plates. Their core advantages stem from the inherent properties of carbon fiber:

Lightweight: Density is only 1.7-1.8g/cm³, about one-fifth that of steel. After reinforcement, it barely adds any additional weight to the structure, making it particularly suitable for load-sensitive scenarios such as old buildings and bridges.

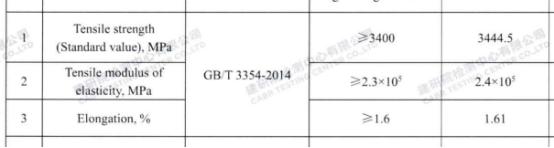

High Strength: Tensile strength can exceed 3000MPa, 8-10 times that of ordinary steel bars. A thin layer (e.g., 200g/m² carbon fiber fabric, only 0.111mm thick) can significantly enhance the load-bearing capacity of the structure.

Corrosion Resistance: Contains no metal components, resisting erosion from harsh environments such as acids, alkalis, salt spray, and humidity. It requires no regular anti-corrosion maintenance and has a service life of over 50 years, making it especially suitable for projects in coastal areas and chemical zones with severe corrosion.

Ease of Construction: No heavy equipment is needed. The process involves cutting, pasting, and curing, making construction efficiency 3-5 times higher than traditional steel plate reinforcement. It causes minimal damage to the original structure, making it ideal for projects requiring high precision, such as historical buildings and indoor spaces.

Choose Dr. Reinforcement Carbon Fiber Fabric for Exceptional Quality with German Technology and Expert Craftsmanship!

II. Performance Showdown: 6 Key Indicators Reveal the Winner

While describing properties is helpful, a quantitative comparison of six key performance indicators between carbon fiber materials and traditional materials more clearly highlights the differences:

Carbon fiber materials outperform traditional materials in strength, lightweightness, corrosion resistance, and construction efficiency. They are only slightly higher in elastic modulus compared to steel (close to but slightly higher than steel), but this difference hardly affects their use in most reinforcement scenarios. In fact, carbon fiber's "high ductility" allows it to better coordinate with concrete structures, avoiding localized stress concentration.

The only caveat: Carbon fiber materials have relatively low shear and compressive strength (after all, they are "fiber" materials, excelling in tension but not compression). Therefore, in pure compression scenarios (e.g., column footing reinforcement), they need to be used in combination with other materials (e.g., carbon fiber wrapping + concrete jackets). This is where they "complement" traditional materials.

III. Application Scenarios: Not the Best, Only the Most Suitable

Although carbon fiber materials have obvious advantages, they are not suitable for all scenarios. Let's examine the "compatibility" of both in different scenarios based on actual engineering cases:

Carbon Fiber Materials: The "Preferred Choice" in These Scenarios

Reinforcement of Old Buildings: For example, brick-concrete residential buildings from the 1980s with insufficient floor load-bearing capacity (unable to meet modern appliance and furniture loads). Applying carbon fiber fabric to the bottom of the floor can increase load-bearing capacity by 30%-50% without adding floor thickness. Construction does not disrupt residents' daily lives (no noise or dust).

Bridge Reinforcement: A highway bridge cracked due to truck overloading. Carbon fiber plates were applied to the tensile zone of the beam bottom, completing reinforcement in just 3 days (compared to over 15 days for traditional steel plate reinforcement). The bridge's weight increased by less than 1%, avoiding impact on its overall stress performance.

Coastal/Chemical Zone Projects: A chemical plant in Shenzhen had steel support structures frequently rusting due to acid-base corrosion. After switching to carbon fiber composite supports, no anti-corrosion maintenance was needed for 5 years, saving nearly RMB 100,000 annually compared to traditional steel.

Historical Building Restoration: Wooden beams in a Qing Dynasty palace in Beijing were decaying. Using steel for reinforcement would have damaged the historical appearance. Carbon fiber fabric (dyed to match the wood color) was applied to the sides of the beams, enhancing load-bearing capacity while preserving the historical appearance.

Traditional Materials: Still "Irreplaceable" in These Scenarios

Heavy Structural Compression Reinforcement: For example, columns in large factories bearing long-term heavy equipment loads, requiring simultaneous improvement in compressive and shear strength. Here, traditional methods like "concrete jackets + steel bars" are more reliable (carbon fiber must be used in combination and cannot bear compressive loads alone).

Temporary Reinforcement Projects: For temporary supports at construction sites, the "recyclability" of steel is more advantageous (carbon fiber materials are difficult to recycle after curing). Steel also has a lower short-term cost, making it suitable for temporary use.

Large-Volume Structural Strengthening: For crack repair in dams and basement walls, sprayed concrete can directly fill cracks and increase structural thickness. Carbon fiber materials are more suitable for "surface reinforcement" and cannot replace the "volume filling" role of concrete.

IV. Economic Analysis: Balancing Short-Term Costs and Long-Term Benefits

Many people believe carbon fiber materials are "expensive," but in reality, engineering economics must consider the "full lifecycle cost," not just the initial purchase price:

Initial Cost: The unit price of carbon fiber fabric is approximately RMB 200-300/m², seemingly higher than steel (Q235 steel plate ≈ RMB 50/m²). However, carbon fiber fabric requires minimal usage (reinforcing 1m² of floor requires only 1-2 layers of carbon fiber fabric, with a total thickness of less than 0.3mm), while steel requires 5-10mm thick plates and involves welding and anti-corrosion treatment (anti-corrosion coating costs ≈ RMB 20/m²). Overall, the initial cost of carbon fiber reinforcement is only 10%-20% higher than steel, far lower than many expect.

Long-Term Cost: Carbon fiber materials require almost no post-construction)maintenance, while steel needs anti-corrosion treatment every 5-10 years (each maintenance costs ≈ RMB 30/m²). Calculated over a 50-year service life, the total maintenance cost for steel is about 15-20 times that of carbon fiber. In severely corrosive environments such as coastal and chemical zones, carbon fiber's long-term economic advantages are even more pronounced.

Indirect Costs: Carbon fiber has a shorter construction cycle, reducing duration by 30%-50%, minimizing project downtime losses (e.g., shopping mall reinforcement, where each day of early reopening can generate additional revenue of tens of thousands of RMB). Moreover, no heavy equipment is needed during construction, reducing site rental and equipment transportation costs. These indirect savings often offset the difference in initial costs.

V. Conclusion: Not "Replacement," but "Upgrade and Complement"

After a comprehensive comparison, we can conclude that carbon fiber materials are not meant to "completely replace" traditional reinforcement materials. Instead, they offer an "upgraded solution" that is more efficient, durable, and lightweight compared to traditional materials.

When projects require lightweightness, high durability, and rapid construction (e.g., old buildings, bridges, coastal projects), carbon fiber materials are the "optimal solution." When projects require compression resistance, recyclability, or temporary use (e.g., heavy structures, temporary supports), traditional materials remain "irreplaceable." More often, the "synergistic use" of both yields the best results—for example, column reinforcement using "carbon fiber fabric wrapping + concrete jackets" leverages carbon fiber's shear strength and concrete's compressive advantage, achieving a "1+12" reinforcement effect.

As carbon fiber material technology continues to advance (e.g., development of low-cost carbon fiber precursors, composite technology of carbon fiber and concrete), it will play a role in more engineering scenarios in the future, driving the reinforcement industry from "heavy-duty" to "high-efficiency" transformation. For engineers and owners, understanding the properties of different materials and choosing the "most suitable" solution based on project needs is the key to ensuring engineering safety and economic efficiency.

Choose Dr. Reinforcement for Trust and Quality!

As a leading brand in China's reinforcement materials industry, Dr. Reinforcement has focused on the R&D and production of carbon fiber fabric for over ten years. Our products are bestselling in over 80 countries and regions worldwide. We own an 8,000㎡ self-operated factory equipped with German Dornier looms, ensuring stable tension and no bubbling in every roll of carbon fiber fabric. Our skilled weavers have over ten years of experience, ensuring meticulous attention to detail in every meter!

High strength, lightweight, corrosion-resistant

Easy construction, reduces construction duration by 30%-50%

Lower full lifecycle cost, more economical in the long run

Contact us now for exclusive discounted quotes and technical solution support! We welcome partnerships with engineers, distributors, and end clients. Let's cooperate with integrity and achieve win-win results!

Have you used carbon fiber reinforcement materials in your projects? Or do you have questions about choosing between the two materials? Feel free to leave a comment below, and let's discuss!

Contact Information:

Email:[email protected]

Whatsapp:86 19121157199

Hot News

Hot News