With global climate warming and the increasing tension surrounding fossil fuels, promoting a green, low-carbon transition has become an international consensus. The automotive industry, as a significant sector for energy consumption and emissions, is facing unprecedented pressure to reduce carbon emissions. Lightweighting, as a key pathway to reduce energy consumption and extend range, has become an essential route for the industry's transformation and upgrading. Among the many lightweight materials, carbon fiber composites stand out due to their exceptional specific strength, specific modulus, fatigue resistance, and design flexibility, gradually becoming a new focus for high-end manufacturing and large-scale application.

I. Body Structural Components: Reshaping the Balance Between Safety and Aesthetics

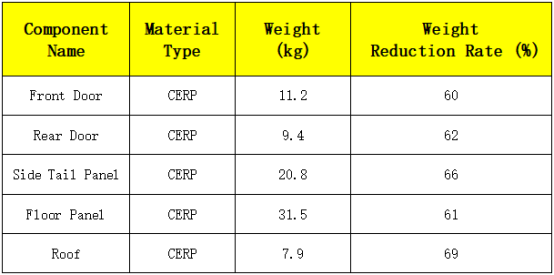

In the field of exterior body panels, carbon fiber composites are widely used in components like doors and engine hoods. They not only meet high standards for aerodynamics and NVH but also achieve significant weight reduction through scientific ply design and resin selection, while enhancing stiffness, impact resistance, and design freedom.

In terms of body frame structures, carbon fiber is gradually replacing steel and aluminum alloys thanks to its outstanding specific strength and specific modulus. Utilizing integrated molding technologies and advanced joining processes enables modular integration of the frame structure, significantly reducing the number of parts and improving both vehicle safety and the level of lightweighting. For example, a certain vehicle model adopts a full carbon fiber passenger cabin, achieving a 62% weight reduction while increasing crash safety performance by over 30%, fully demonstrating the potential of synergistic innovation between material and structure.

II. Chassis System: Advancing Both Precision Handling and Comfort

Carbon fiber composites also perform excellently in chassis systems, particularly suitable for key components such as suspension springs, control arms, and shock absorbers. Taking shock absorbers as an example, using carbon fiber not only reduces weight by 15%–25% but also improves fatigue resistance by 2–3 times, enhances the system's dynamic response capability, effectively reduces vibration transmission, and improves ride comfort.

In drive shaft applications, carbon fiber material can achieve a 25%–40% weight reduction while ensuring strength and stiffness, and reduce vibration noise by 3–8 decibels, contributing to the simultaneous optimization of vehicle NVH performance and transmission efficiency.

III. Powertrain System: Efficient Protection and Quiet Operation

As an important component of the powertrain, engine covers made of carbon fiber composites can achieve precise matching with the engine bay through autoclave processes. Compared to traditional aluminum alloy covers, the carbon fiber version can reduce weight by 30%–40%, increase stiffness by 20%–30%, significantly suppress vibration and noise, and optimize the working environment of the engine compartment.

IV. Innovative Bumper: Pultrusion Process Breaks Structural Boundaries

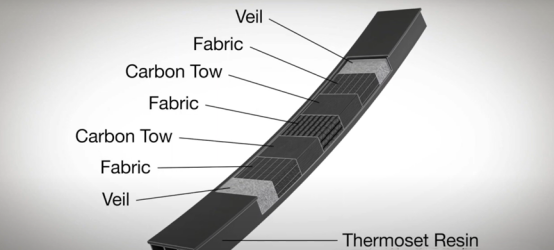

Taking the Chevrolet Corvette Stingray as an example, its curved carbon fiber rear bumper beam demonstrates the capability of pultrusion technology in manufacturing highly complex components. This technology enables high-strength, high-surface-quality mass production within compact equipment space by precisely controlling the introduction and molding of multiple layers of carbon fiber and fabrics, with an annual production capacity of over 70,000 units, setting a benchmark for the large-scale application of composites in safety structural components.

V. Xiaomi SU7 Ultra: A Milestone in Mass Production of Carbon Fiber

Xiaomi Motors successfully pushed the carbon fiber front hood into mass production in the SU7 Ultra model, marking the material's formal entry into the market of models with monthly sales reaching tens of thousands, breaking through the "exclusive for the nobility" application bottleneck. Its front hood uses Toray carbon fiber, with both the inner and outer panels consisting of 3 layers of carbon fabric, undergoing 11 precise processes. Molds are made of high-strength P20 steel to withstand the high temperature and pressure environment of the autoclave. Each mold is assigned two skilled workers for manual layup, with texture alignment accuracy controlled within 0.5 mm. Curing under conditions of 145°C and 0.7 MPa for 6 hours ensures high stability and excellent performance of the component.

Behind this "phenomenal breakthrough" lies the maturity and synergy of the entire carbon fiber industry chain – from the performance improvement of raw materials to the standardization and automation of molding processes, driving continuous cost reduction and laying the foundation for the popularization of composite materials in more vehicle models.

Dr. Reinforcement: Your Carbon Fiber Solution Partner

As a deep cultivator in the field of carbon fiber materials, Dr. Reinforcement leverages its own modern production base of 8,000 square meters, advanced equipment such as German Dornier weaving machines, ensuring uniform tension, no bubbling, and stable quality during the weaving process of carbon fiber fabric. We possess a professional weaving team with over ten years of experience. Our products are certified with the ISO 9001 Quality Management System and CE EU standards, and we have provided highly reliable carbon fiber fabric products to millions of customers globally, with a repurchase rate exceeding 50%.

We deeply understand the high requirements for material performance and consistency in automotive lightweighting, and are committed to providing customers with one-stop services from material selection and structural design to process support. Whether for body panels, chassis components, or innovative structural parts, Dr. Reinforcement can assist you in achieving product upgrades and technological innovation through a cost-effective, rapidly responsive cooperation model.

If you are looking for a reliable, high-performance carbon fiber material supplier, please feel free to contact us! Dr. Reinforcement will provide you with professional, customized product solutions to jointly create a lightweight future.

Email:[email protected]

Whatsapp:86 19121157199

Hot News

Hot News